Mobile:+86-311-808-126-83

Email:info@ydcastings.com

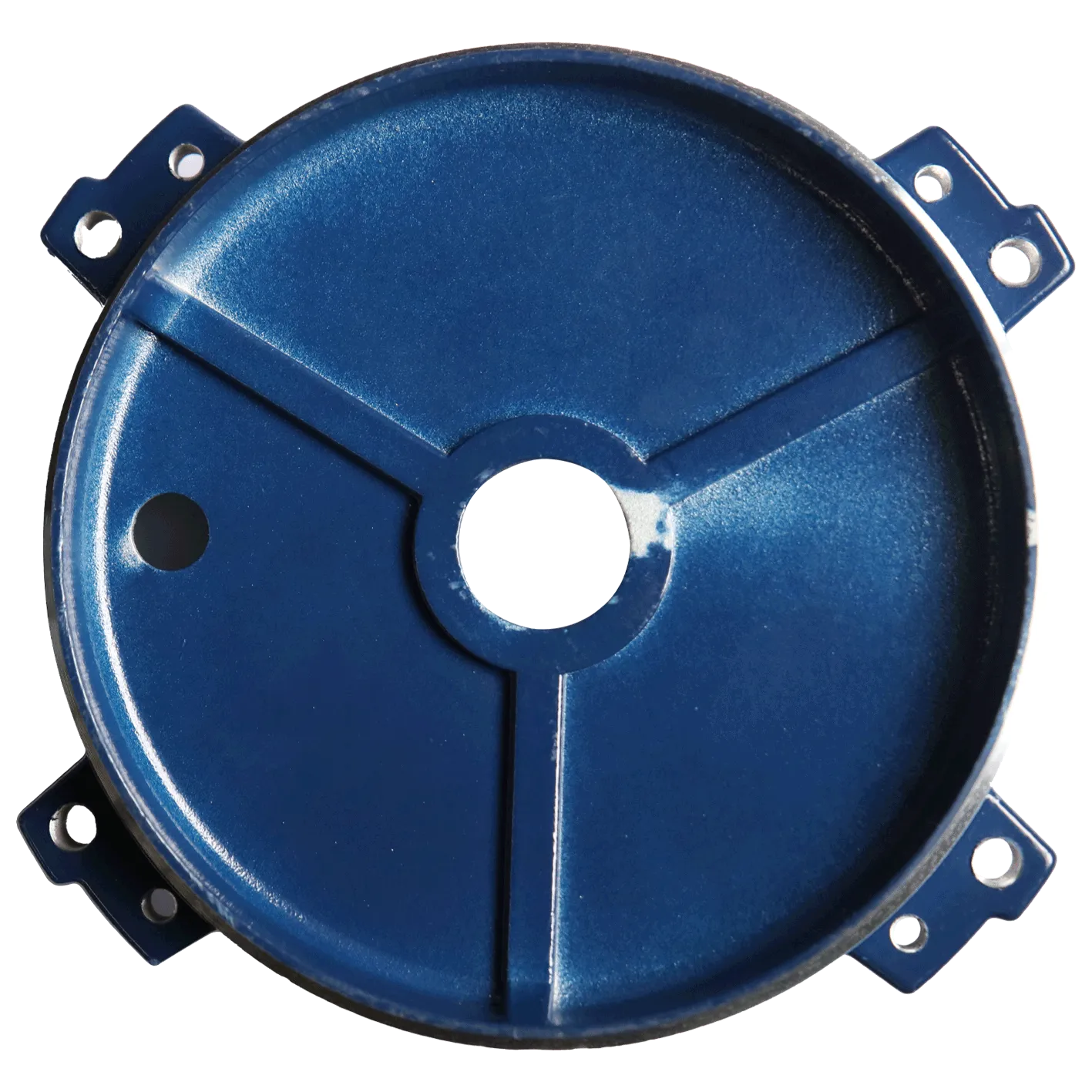

impeller

Impellers are critical components in various industrial applications, serving as pivotal elements in the functionality of equipment ranging from pumps to turbines. Their primary function is to convert mechanical energy from a motor into kinetic energy, facilitating the movement of fluids. Expertise in the design and application of impellers is essential for ensuring optimal performance and efficiency in any related system.

In the realm of fluid dynamics, the design of an impeller significantly influences the efficacy of a pump or turbine. Notably, the impeller's blades are crafted to maximize fluid flow while minimizing turbulence. This delicate balance is achieved through meticulous engineering that considers the fluid's properties, such as viscosity and density, alongside the intended application of the impeller. Real-world experience demonstrates that even slight modifications in blade curvature or angle can lead to significant improvements in performance, attesting to the expertise required in impeller design.

Professionals in industries reliant on impeller technology often emphasize the importance of material selection. The environment in which the impeller will operate demands materials that can withstand specific conditions, be it corrosion, erosion, or extreme temperature variations. From stainless steel to advanced composites, the choice of material is guided by years of authoritative research and field trials. This not only ensures the longevity of the impeller but also upholds the trustworthiness of the system's overall performance.

Moreover, the authority of impeller manufacturers is typically grounded in their ability to provide solutions tailored to individual needs. Customization, driven by sophisticated computational fluid dynamics simulations, allows for the fabrication of impellers that meet precise specifications. This bespoke approach underscores a commitment to excellence and is a testament to the manufacturer's expertise, fostering trust among discerning clients.

impeller

To maintain such high standards, continuous innovation in impeller technology is vital. This includes the integration of cutting-edge technology such as 3D printing, which affords precise control over the manufacturing process, allowing for greater intricacy in blade designs. Such advancements not only enhance performance but also offer opportunities to explore new applications across various sectors. The push towards innovative solutions is driven by an authoritative understanding of both current challenges and future possibilities in fluid mechanics.

In practice, the true measure of an impeller's success is often reflected in user satisfaction and feedback. Professionals who utilize these components regularly provide invaluable insights into performance and areas for improvement. This exchange of real-world experience between users and manufacturers enriches the design and development process, ensuring that the products not only meet but exceed industry standards.

Ultimately, the synthesis of experience, expertise, authoritativeness, and trustworthiness enables the production of impellers that are both reliable and efficient. Whether in pumping water through municipal systems or channeling chemical processes in industrial plants, impellers remain indispensable. The commitment to refining their design and application is a testament to their crucial role in advancing modern engineering solutions.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025