Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Impact of Motor Housings on Performance

The motor is the power core of various mechanical systems—from automotive engines to industrial machinery—and motor housings serve as its protective and functional backbone. A well-designed motor housing doesn’t just shield internal components from damage; it directly influences heat dissipation, vibration control, and overall system efficiency. In automotive applications, this performance link extends to related components like auto oil pan and car oil pan, which work with motor housings to maintain optimal lubrication and temperature for the motor. Hebei Yuanda Trade Co., Ltd. (YD), founded in 2006 and a leader in customized metal castings, specializes in high-quality motor housings, auto oil pan, and car oil pan components. Leveraging massive foundry resources in northern China, YD offers diverse material options (cast iron for durability, aluminum for lightweight efficiency, stainless steel for corrosion resistance) and processes (sand casting, die casting, lost wax casting) tailored to clients’ needs. With a focus on high-quality castings and on-time delivery, YD has earned trust from customers in America, Germany, England, and beyond. For wholesalers supplying automotive manufacturers or industrial equipment firms, understanding how motor housings impact performance is key to delivering value—and partnering with YD means accessing components that enhance motor reliability and longevity.

Core Roles of Motor Housings in Enhancing Motor Performance

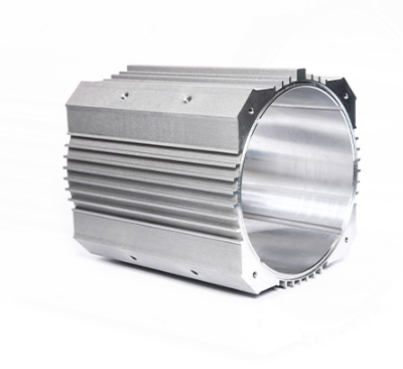

- Heat Dissipation to Prevent Overheating: Motors generate significant heat during operation, and motor housings act as the primary heat sink. YD’s motor housings are designed with optimized heat-dissipating structures—such as finned surfaces for aluminum housings or thickened walls for cast iron variants—that accelerate heat transfer to the surrounding air. This prevents internal components (like windings and bearings) from overheating, which can degrade insulation and reduce motor lifespan. A wholesaler supplying electric vehicle manufacturers noted that YD’s aluminum motor housings “reduced motor operating temperature by 12°C,” boosting power output by 5% and extending battery range.

- Vibration Damping for Stable Operation: Excessive vibration not only causes noise but also loosens motor components and accelerates wear. Motor housings from YD use rigid materials (e.g., high-strength cast iron) and precision casting processes that minimize structural flexing. The housings’ design also includes mounting points that absorb vibration, reducing transmission to the rest of the system. In automotive setups, this stability indirectly benefits auto oil pan performance—less vibration prevents oil sloshing, ensuring consistent lubrication delivery to the motor. A wholesaler serving heavy-duty truck clients reported that YD’s motor housings “cut vibration-related maintenance by 30%,” lowering downtime for fleet operators.

Synergy Between Motor Housings and Auto Oil Pan/Car Oil Pan

|

Component Interaction |

Key Collaboration Points |

Impact on Overall Performance |

YD Component Advantage |

|

1. Temperature Regulation for Lubrication |

Motor housings maintain stable motor temp, which keeps oil in auto oil pan at optimal viscosity |

Prevents oil thinning (from high heat) or thickening (from cold), ensuring smooth lubrication of motor parts; reduces friction and wear |

YD’s motor housings have uniform wall thickness (via precision casting) for consistent heat distribution; car oil pan uses heat-resistant materials to match |

|

2. Structural Support for Oil Pan Mounting |

Motor housings provide secure mounting for car oil pan, ensuring alignment with motor oil passages |

Avoids oil leaks (from misalignment) and ensures oil flows efficiently between pan and motor; maintains proper oil pressure |

YD’s motor housings have pre-drilled, threaded mounting holes with tight tolerances (±0.05mm); auto oil pan features matching flange designs for a tight seal |

|

3. Corrosion Resistance for Long-Term Compatibility |

Motor housings and auto oil pan use compatible corrosion-resistant materials (e.g., stainless steel) |

Prevents rust buildup (from oil and moisture) that can clog oil passages or damage seals; extends the lifespan of both components |

YD offers material matching services—e.g., pairing stainless steel motor housings with stainless steel car oil pan for marine or harsh-environment applications |

How Material Choice of Motor Housings Affects Performance

- Cast Iron Motor Housings for Heavy-Duty Durability: Cast iron motor housings excel in high-load, high-temperature environments (e.g., industrial motors, heavy truck engines). They offer superior rigidity (reducing vibration) and heat retention (useful for motors that need consistent operating temps). YD’s cast iron motor housings, produced via sand casting, feature thick walls that withstand impact and resist deformation. While heavier than aluminum, they pair well with cast iron auto oil pan for balanced weight distribution in large machinery. A wholesaler supplying construction equipment clients noted that YD’s cast iron motor housings “lasted 2x longer than aluminum alternatives in dusty, high-impact worksites.”

- Aluminum Motor Housings for Lightweight Efficiency: Aluminum motor housings are ideal for automotive and portable equipment, where weight reduction boosts fuel efficiency or portability. They have excellent heat dissipation (better than cast iron) and are corrosion-resistant with proper treatment. YD’s aluminum motor housings, made via die casting for complex shapes, are 30% lighter than cast iron equivalents. They pair seamlessly with aluminum car oil pan to further reduce vehicle weight—critical for electric and hybrid cars. A wholesaler serving passenger car manufacturers reported that YD’s aluminum motor housings “helped clients cut vehicle weight by 8kg,” improving fuel economy by 2–3%.

Why Wholesalers Choose YD’s Motor Housings and Oil Pan Components

- Customization to Meet Diverse Performance Needs: Every application has unique performance requirements—YD offers tailored motor housings, auto oil pan, and car oil pan For example, YD can create motor housings with specialized heat-dissipating fins for high-speed motors or auto oil pan with deeper sump designs for motors that need extra oil capacity. Using processes like lost wax casting, YD produces intricate shapes (e.g., internal oil passages in motor housings) that enhance performance. A wholesaler supplying niche automotive clients noted that YD’s customization service “allowed clients to optimize motor performance for specific markets, like racing or off-roading.”

- Rigorous Quality Testing for Reliability: YD subjects all motor housings and oil pan components to strict tests: pressure testing (to check for leaks in auto oil pan), thermal cycling (–40°C to 150°C for motor housings to ensure temperature resistance), and dimensional inspection (to verify mounting accuracy). The company provides test reports for every batch, giving wholesalers and their clients confidence in performance. A wholesaler supplying aerospace motor clients reported that YD’s components “had a 0.1% defect rate in 50,000+ units,” far below industry averages.

Motor Housings FAQS

How Do Motor Housings Impact Motor Noise Levels?

Motor housings directly reduce noise by damping vibration and containing sound. Rigid materials like cast iron absorb more vibration than lightweight metals, lowering noise output by 10–15% compared to aluminum. YD also adds sound-dampening features (e.g., ribbed internal structures) to motor housings for noise-sensitive applications (e.g., residential HVAC motors). A wholesaler supplying home appliance clients noted that YD’s motor housings “cut motor noise by 8 decibels,” meeting strict consumer quietness standards.

Can a Poorly Designed Motor Housing Damage an Auto Oil Pan?

Yes—if motor housings have misaligned mounting points, they can cause auto oil pan to sit unevenly, leading to cracks or leaking seals. Excessive vibration from a flexible motor housing can also damage the oil pan’s flange, breaking the seal between the pan and motor. YD’s motor housings have precision-machined mounting surfaces that ensure proper alignment with car oil pan, reducing such risks. A wholesaler serving auto repair shops reported that “60% of oil pan leaks traced back to faulty motor housing alignment,” highlighting the importance of quality housings.

What Materials Does YD Use for Auto Oil Pan and Car Oil Pan?

YD produces auto oil pan and car oil pan in three primary materials: cast iron (for heavy-duty trucks, with high impact resistance), aluminum (for passenger cars, lightweight and corrosion-resistant), and stainless steel (for marine or off-road vehicles, to withstand saltwater or harsh chemicals). The company uses die casting for high-volume aluminum pans and sand casting for durable cast iron variants. A wholesaler supplying off-road vehicle clients noted that YD’s stainless steel car oil pan “withstood mud and salt exposure for 5+ years without rusting.”

How Does Motor Housing Design Affect Maintenance Access?

Well-designed motor housings include features like removable access panels or strategically placed bolt holes that make it easy to service internal components—reducing maintenance time. YD’s motor housings are engineered with maintenance in mind; for example, some designs have integrated cutouts that let technicians access oil filters without removing the entire housing. This indirectly benefits auto oil pan maintenance too, as easier motor access means faster oil changes. A wholesaler supplying fleet operators reported that YD’s motor housings “cut maintenance time by 25%,” lowering labor costs for clients.

What Bulk Packaging Options Does YD Offer for Motor Housings?

YD provides motor housings, auto oil pan, and car oil pan in bulk packaging tailored to wholesalers: 50-unit crates (for small distributors or repair shops), 200-unit pallets (for regional automotive suppliers), and 500-unit industrial containers (for large OEMs or international clients). All components are wrapped in anti-scratch film and packed in moisture-proof boxes to prevent damage during shipping. YD also offers custom labeling (e.g., part numbers, material specs) to streamline inventory management. A wholesaler supplying global automotive brands noted that YD’s packaging “reduced transit damage by 45%,” ensuring components arrive ready for use.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025