Mobile:+86-311-808-126-83

Email:info@ydcastings.com

how to cast in bronze

How to Cast in Bronze A Comprehensive Guide

Bronze casting is a time-honored art form that has been practiced for thousands of years, dating back to ancient civilizations. The allure of bronze, with its warm color and durability, continues to captivate artists and metalworkers today. Whether you’re an experienced sculptor or a novice looking to explore metal casting, understanding the bronze casting process is essential. In this article, we will delve into the steps involved in casting in bronze, key techniques, and essential tips for success.

Understanding Bronze

Bronze is an alloy primarily made of copper, usually combined with tin, though other metals such as aluminum, manganese, and nickel can also be added to create various types of bronze with different properties. The melting point of bronze is typically around 950 to 1,050 degrees Celsius (1,742 to 1,922 degrees Fahrenheit), making it ideal for casting. Its corrosion resistance and ability to withstand wear make it a popular choice for sculptures, jewelry, and industrial applications.

Preparing Your Design

Before you begin the casting process, you need a design or model to work from. This can be made from various materials, such as clay, wax, or even a 3D-printed object. If you are using the lost-wax casting method—which is one of the most common techniques—you will create a detailed wax model of your design. Once the model is complete, it is important to consider the size and shape, ensuring it can be efficiently cast and will yield the desired final product.

Creating the Mold

1. Shell Mold Method For the shell mold technique, the wax model is coated in a ceramic shell material. This layer needs to be carefully built up to provide a strong mold. After the shell has dried completely, it is heated to melt out the wax, leaving behind a hollow ceramic mold that will be used for casting.

2. Sand Casting Alternatively, you can use sand casting, where a sand mixture is compacted around a mold frame. The wax model (or a solid version of your design) is pressed into the sand, and the mold is created by splitting the frame and removing the model. This method is often used for larger sculptures and can be a more accessible option for beginners.

how to cast in bronze

Melting the Bronze

Once your mold is ready, it’s time to melt the bronze. This requires a furnace capable of reaching the necessary temperatures. Safety is paramount—always wear appropriate protective gear, including heat-resistant gloves and goggles. The bronze is typically placed in a crucible, which is then heated until the metal reaches a molten state.

Pouring the Bronze

With the bronze melted, you need to pour it into the mold. This stage requires precision and steadiness. The molten metal should be poured slowly and steadily to avoid air bubbles, which can create weaknesses in the final piece. If you’re using the lost-wax method, ensure that the ceramic shell mold can withstand the heat of the molten bronze to prevent breakage.

Finishing Touches

Once the bronze has cooled and solidified, it’s time to break open the mold. For shell molds, careful chipping away is required, whereas sand molds can be broken down more straightforwardly. After the removal of the mold, the bronze casting will have a rough surface that needs to be smoothed out. This is typically done through grinding, sanding, and polishing to achieve the desired finish.

If your design features intricate details, it may require additional work, including patination to alter the surface color or applying protective coatings to enhance durability. The finishing process not only adds aesthetic value but also contributes to the longevity of the bronze piece.

Conclusion

Casting in bronze is both an art and a science, requiring careful planning, precise execution, and a commitment to safety. As you embark on your bronze casting journey, remember that practice is key. Continue to experiment with different techniques and molds to develop your skills. Whether creating a small sculpture or a large installation, the rewards of working with bronze are immense—producing timeless pieces that may be cherished for generations to come. By following the steps outlined in this guide and maintaining a spirit of curiosity and creativity, you’re well on your way to mastering the art of bronze casting.

-

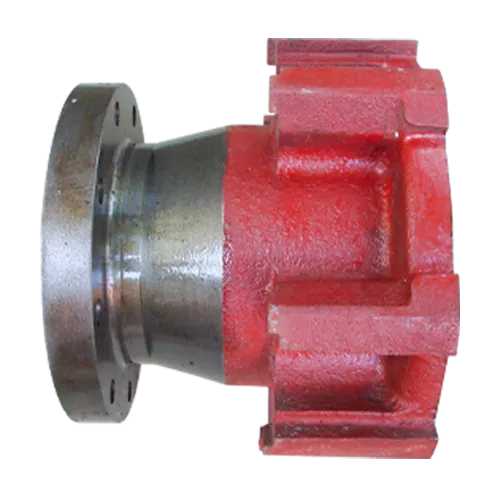

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025