Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

High-Quality Pump Connector Castings-Hebei Yuanda Trade Co., Ltd.

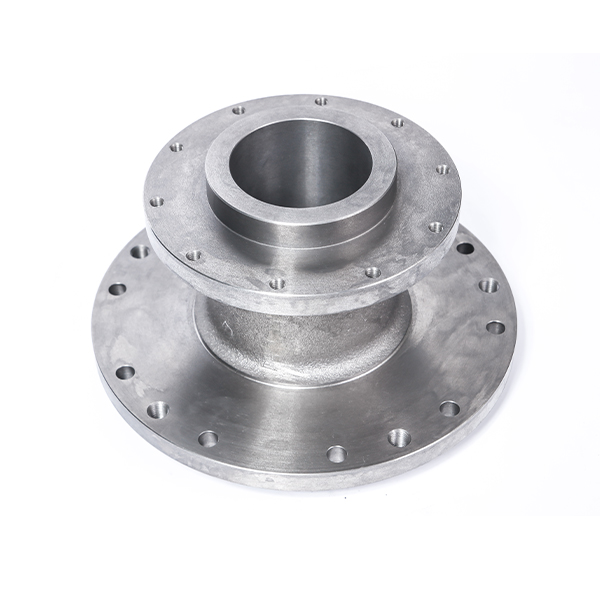

Connector castings are essential components in pump equipment, serving as critical links between various parts and piping systems. These castings are typically manufactured from robust materials such as cast iron, stainless steel, or aluminum alloys, chosen for their ability to withstand harsh operating conditions. The design and material selection of connector castings play a pivotal role in determining the performance, stability, and longevity of pumping systems. By ensuring seamless integration and minimizing risks of leakage or structural failure, high-quality connector castings significantly enhance the efficiency and reliability of pump equipment. For more information, visit the product page or explore the company website.

Key Features and Technical Specifications

Connector castings are engineered to meet stringent quality standards, with a focus on precision, durability, and performance. Below is a detailed overview of their technical specifications:

| Parameter | Details |

|---|---|

| Product Name | Connectors |

| Weight Range | 5-50 kg |

| Material | GG25-Cast Iron |

| Casting Process | Resin Sand Casting |

| Shape Accuracy | High precision, ensuring optimal sealing performance |

| Dimensional Accuracy | Minimal size error to meet strict design requirements |

| Surface Quality | Smooth finish with no sand holes or air pockets |

Advantages of Precision Connector Castings

The advantages of high-quality connector castings are multifaceted, addressing both functional and operational requirements of pump systems. One of the most critical benefits is their corrosion resistance, which is essential for maintaining structural integrity in environments exposed to moisture, chemicals, or extreme temperatures. Wear resistance further ensures that these components can endure prolonged use without degradation, reducing the need for frequent replacements. Additionally, their pressure resistance makes them ideal for high-stress applications, such as industrial pumping systems or hydraulic machinery.

Another significant advantage is the smooth surface finish of these castings. A defect-free surface minimizes the need for post-casting machining, thereby improving production efficiency and reducing labor costs. According to the National Institute of Standards and Technology (NIST), "surface quality in casting processes directly impacts the operational efficiency and lifespan of mechanical components" (NIST, 2023). This aligns with the design philosophy of modern connector castings, which prioritize both performance and cost-effectiveness.

Applications in Pump Equipment

Connector castings are indispensable in a wide range of pump equipment, including water pumps, industrial pumps, and hydraulic systems. Their role in connecting different components ensures that fluid flow remains consistent and leakage is minimized. For instance, in water pump impeller systems, the precision of connector castings directly affects the pump's efficiency and reliability. A poorly designed casting can lead to misalignment, increased wear, and reduced energy efficiency.

Moreover, these castings are crucial in residential and commercial water supply systems, where their corrosion resistance and durability ensure long-term performance. In industrial settings, they are used in pump impeller assemblies and cap ends, which are critical for maintaining system integrity. The resin sand casting process employed in their production allows for complex geometries, making them suitable for specialized applications such as high-pressure hydraulic systems or chemical processing equipment

Advanced Manufacturing Techniques

The production of connector castings involves cutting-edge technologies to achieve the required precision and quality. The resin sand casting process is a key innovation in this domain, utilizing advanced molds and equipment to ensure high shape accuracy and dimensional stability. This method not only reduces the need for secondary machining but also minimizes material waste and energy consumption, aligning with modern sustainability goals.

According to NIST, "resin sand casting has become a standard practice in the manufacturing of high-precision components due to its ability to produce complex shapes with minimal defects" (NIST, 2023). This is particularly relevant for pump castings, where even minor deviations can compromise performance. The use of fine molds and automated casting equipment further enhances the consistency and reliability of the final product.

Company Background: Hebei Yuanda Trade Co., Ltd.

Hebei Yuanda Trade Co., Ltd., a leading manufacturer of pump castings and connector components, has established itself as a trusted name in the industry. With a focus on quality, innovation, and customer satisfaction, the company has built a reputation for delivering high-performance products that meet global standards. Their expertise in resin sand casting and precision engineering enables them to cater to a diverse range of applications, from residential water systems to industrial hydraulic equipment

As a company committed to sustainable manufacturing practices, Hebei Yuanda Trade Co., Ltd. integrates eco-friendly technologies into its production processes. This approach not only reduces environmental impact but also ensures that their products are cost-effective and long-lasting. For more details about their services, visit the company website.

Product Images and Visuals

Below are key visuals of connector castings and related components:

Read More About pumpe impeller

Read More About water pump impeller

Conclusion

Connector castings are a cornerstone of modern pump systems, offering a blend of precision, durability, and versatility. Their role in ensuring sealing performance, pressure resistance, and corrosion protection makes them indispensable in both industrial and residential applications. With advanced manufacturing techniques and a commitment to quality, companies like Hebei Yuanda Trade Co., Ltd. continue to set benchmarks in the industry. For those seeking reliable and high-performance pump components, exploring their product range is a step toward achieving operational excellence.

References

National Institute of Standards and Technology (NIST). "Resin Sand Casting in Modern Manufacturing." 2023. https://www.nist.gov

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025