Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Precision Aluminium Metal Casting Solutions | Custom Quality Parts

The Strategic Imperative of aluminium metal casting in Modern Industry

In the intricate landscape of B2B manufacturing, the demand for lightweight, high-strength, and corrosion-resistant components is ever-growing. aluminium metal casting stands as a cornerstone technology, offering unparalleled versatility and economic advantages for a myriad of industrial applications. This process transforms raw aluminium alloys into complex shapes with exceptional precision, making it indispensable across sectors ranging from automotive and aerospace to petrochemical and renewable energy.

The selection of appropriate metal castings and casting techniques, such as green sand metal casting or aluminum die casting, directly impacts product performance, cost-efficiency, and overall project timelines. This detailed overview delves into the technical intricacies, strategic benefits, and real-world applications of modern aluminium casting solutions, providing crucial insights for engineers, procurement specialists, and project managers.

With continuous advancements in metallurgy and process control, the capabilities of aluminium alloy for casting are expanding, allowing for the creation of components that meet increasingly stringent technical specifications and performance demands.

Detailed Process Flow of aluminium metal casting

The manufacturing of aluminium metal casting components involves a meticulously controlled, multi-stage process designed to achieve optimal material integrity and dimensional accuracy. While specific steps can vary depending on the chosen casting method (e.g., sand casting, die casting, permanent mold casting), a general framework ensures consistent quality:

1. Mold Design & Pattern Making

CAD models are translated into patterns (for sand casting) or dies (for die casting/permanent mold). Material properties of the selected aluminium alloy for casting are paramount in this stage.

2. Material Preparation & Melting

High-grade aluminium alloy ingots are melted in furnaces, often with precise temperature and atmospheric control to prevent oxidation and gas absorption. Common alloys include A356, A380, and A413, each selected for specific mechanical properties.

3. Pouring/Injection

Molten metal is poured into sand molds (green sand metal casting), injected into metal dies (aluminum die casting), or gravity-fed into permanent molds. The technique chosen optimizes for volume, surface finish, and intricate geometry.

4. Cooling & Solidification

The cast metal cools and solidifies within the mold. Controlled cooling rates are critical to achieve desired grain structure and prevent defects such as shrinkage porosity or hot tearing.

5. Demolding & Shakeout

Once solidified, the casting is removed from the mold. For sand casting, this involves breaking away the sand; for die casting, ejector pins push the part out.

Excess material, such as gates, risers, and flash, is removed. This can involve sawing, grinding, or specialized trimming machines. Precision is key to minimizing post-processing.

7. Heat Treatment (If Required)

Many aluminium alloys undergo heat treatment (e.g., T4, T6) to enhance mechanical properties like tensile strength, yield strength, and hardness, improving the service life of the component.

8. Machining (CNC)

For components requiring tight tolerances or specific features not achievable through casting alone, CNC machining is employed. This ensures final dimensions meet exacting specifications.

9. Inspection & Testing

Castings undergo rigorous inspection, including visual inspection, dimensional checks, NDT (Non-Destructive Testing) like X-ray or penetrant testing, and mechanical property testing. Adherence to standards like ISO 9001 and ANSI is verified.

10. Surface Finishing & Packaging

Finally, components may receive surface treatments (e.g., anodizing, powder coating) for enhanced corrosion resistance or aesthetic appeal, then are carefully packaged for shipment.

These processes ensure that the final aluminium metal casting product not only meets but often exceeds the demanding specifications of target industries such as petrochemical, metallurgy, and water supply & drainage. The inherent advantages, like excellent energy saving characteristics due to lightweighting, and superior corrosion resistance, make aluminium castings a preferred choice for critical infrastructure components like flanges, valves, and pump housings.

Current Industry Trends in aluminium metal casting

The landscape of aluminium metal casting is continually evolving, driven by demands for greater efficiency, sustainability, and advanced material performance. Several key trends are shaping the future of this vital industry:

- Lightweighting for Energy Efficiency: The automotive and aerospace industries continue to push for lighter components to improve fuel efficiency and reduce emissions. Advanced aluminium alloys and casting techniques are crucial in achieving these weight reductions without compromising structural integrity.

- Additive Manufacturing Integration: While not a replacement for traditional casting, additive manufacturing (3D printing) is increasingly used for rapid prototyping of complex molds and cores, significantly shortening development cycles for new metal castings.

- Sustainable Practices: There's a growing emphasis on green manufacturing, including the use of recycled aluminium, optimizing energy consumption in melting processes, and reducing waste in green sand metal casting. This aligns with broader corporate social responsibility goals.

- Advanced Simulation and AI: Sophisticated simulation software is used to predict casting behavior, optimize mold designs, and minimize defects before physical production. AI and machine learning are being deployed for real-time process monitoring and quality control, particularly in aluminum die casting.

- High-Performance Alloys: Research into new aluminium alloy for casting with enhanced properties – such as higher strength-to-weight ratios, improved fatigue resistance, and superior performance at elevated temperatures – is ongoing to meet the demands of advanced applications.

- Automation and Robotics: Increased automation in pouring, demolding, fettling, and inspection processes is improving efficiency, safety, and consistency across casting operations.

These trends underscore a commitment to innovation, quality, and environmental stewardship, ensuring aluminium metal casting remains a competitive and relevant manufacturing solution.

Technical Specifications and Parameters for Aluminium Castings

The performance of aluminium metal casting components is defined by a range of critical technical specifications. These parameters are vital for engineers and designers to ensure that the chosen alloy and casting method meet the operational requirements of the end application. Below is a representative table of properties for common aluminium alloys used in casting, along with typical specifications for a cast aluminium flange.

Aluminium Alloy for Casting: Comparative Properties

| Property | A356.0-T6 (Heat-Treated) | A380.0 (Die Cast) | A413.0 (Corrosion-Resistant) |

|---|---|---|---|

| Typical Application | Aerospace, Automotive, Pump Housings | Automotive, Electrical Enclosures, Gear Cases | Marine, Architectural, Pressure Vessels |

| Tensile Strength (MPa) | 290 - 320 | 310 - 330 | 240 - 270 |

| Yield Strength (MPa) | 205 - 225 | 145 - 165 | 110 - 130 |

| Elongation (%) | 3 - 6 | 1 - 3 | 2 - 4 |

| Hardness (Brinell) | 70 - 90 | 70 - 80 | 60 - 70 |

| Density (g/cm³) | 2.68 | 2.74 | 2.69 |

| Corrosion Resistance | Good | Good | Excellent |

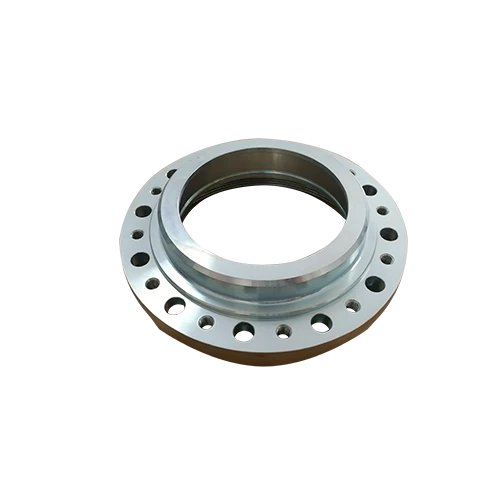

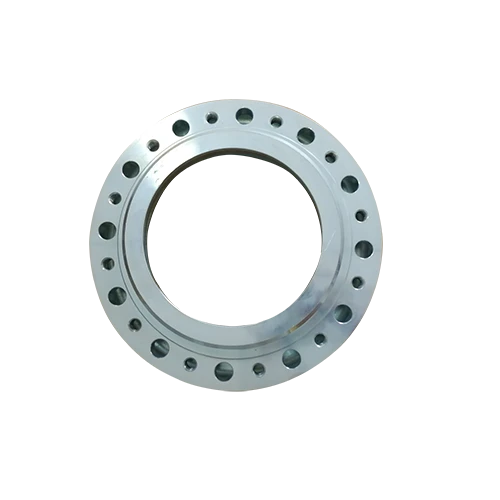

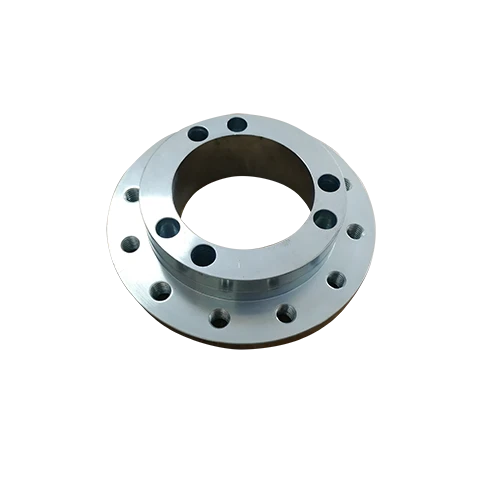

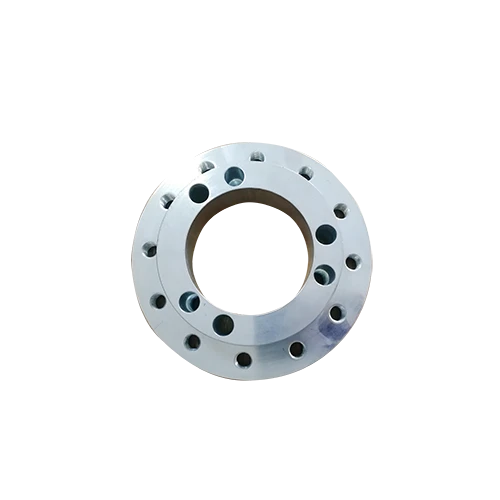

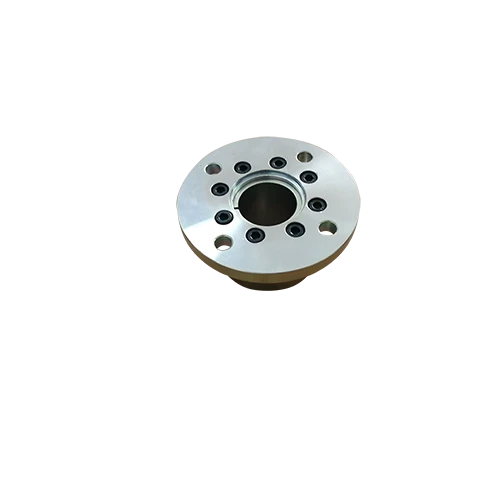

Product Specification: Cast Aluminium Flange (Example)

| Specification | Details |

|---|---|

| Material | A356.0-T6 Aluminium Alloy (or custom alloy) |

| Manufacturing Process | Permanent Mold Casting & CNC Machining |

| Pressure Rating | ANSI Class 150 / PN16 (up to 275 PSI / 16 Bar) |

| Nominal Diameter (DN) | DN50 - DN600 (2 inches - 24 inches) |

| Face Type | Raised Face (RF) or Flat Face (FF) |

| Testing Standards | ISO 9001, ASTM B26, ASME B16.5, EN 1092-1 |

| Surface Finish | Ra 3.2-6.3 µm (machined surfaces) |

| Dimensional Tolerance | ISO 8062-3 DCTG 6-8, or per customer drawing |

| Weight Reduction vs. Steel | Approx. 60-70% lighter |

| Service Life | 20+ years under specified conditions |

Application Scenarios for Aluminium Castings

The versatility of aluminium metal casting enables its use across a broad spectrum of industries, providing robust and efficient solutions for critical components. Its unique combination of properties makes it ideal for challenging environments.

- Petrochemical Industry: Aluminium castings are frequently used for components like pump housings, valve bodies, and various pipe fittings and flanges in corrosive or high-temperature environments where lightweight and superior corrosion resistance are crucial. Their non-sparking properties are also valuable in hazardous zones.

- Metallurgy & Mining: Equipment for material handling, processing, and separation often requires durable, corrosion-resistant parts. Aluminium castings, including specialized metal castings, offer excellent service life even in abrasive and chemically aggressive settings.

- Water Supply & Drainage Systems: Flanges, impellers, and manifold components for water treatment plants, pumping stations, and municipal infrastructure benefit from aluminium's corrosion resistance against water and various chemicals, ensuring longevity and reduced maintenance costs.

- Automotive & Transportation: Engine blocks, transmission cases, wheel hubs, suspension components, and chassis parts extensively utilize aluminum die casting for lightweighting, which directly translates to improved fuel efficiency and reduced emissions.

- Aerospace: Critical structural components, engine parts, and housings for electronic systems leverage the high strength-to-weight ratio and precise dimensional control offered by advanced aluminium alloy for casting.

- Renewable Energy: Components for wind turbines (nacelle covers, gearbox housings), solar panel mounting systems, and hydroelectric equipment often employ large-scale aluminium castings due to their durability and ability to withstand environmental stressors.

The ability to customize these castings for specific pressure ratings, temperature ranges, and chemical compatibilities ensures optimal performance and safety in these demanding applications.

Technical Advantages of aluminium metal casting

Choosing aluminium metal casting over other manufacturing methods or materials offers distinct technical and economic advantages:

- Exceptional Strength-to-Weight Ratio: Aluminium alloys provide excellent mechanical strength at a fraction of the weight of steel or cast iron, leading to reduced overall component weight. This is critical for moving parts, transportation applications, and reducing foundational loads.

- Superior Corrosion Resistance: Aluminium naturally forms a protective oxide layer, making it highly resistant to corrosion in various atmospheric and chemical environments. This enhances the service life of components, particularly in outdoor, marine, or industrial settings. For applications requiring even greater resistance, specialized aluminium alloy for casting or surface treatments can be applied.

- Design Flexibility and Intricate Geometries: Casting processes, especially aluminum die casting, allow for the creation of complex, near-net-shape parts with fine details, thin walls, and integrated features, minimizing the need for extensive post-machining. This design freedom facilitates innovative product development.

- Excellent Thermal and Electrical Conductivity: Aluminium is an effective conductor of both heat and electricity, making it suitable for heat sinks, electrical housings, and components requiring efficient thermal management.

- Cost-Effectiveness for Volume Production: While initial tooling costs can be higher for methods like die casting, the high production rates, reduced material waste, and minimal post-processing often make aluminium metal castings highly cost-effective for large-volume manufacturing compared to alternatives like stainless steel casting for similar forms.

- Recyclability and Sustainability: Aluminium is 100% recyclable without loss of properties, contributing to a circular economy. Utilizing recycled content in metal castings significantly reduces energy consumption and environmental impact.

- Good Machinability: Although casting often produces near-net shapes, when machining is required, aluminium is relatively easy to machine, allowing for tight tolerances and smooth finishes.

Vendor Comparison and Selection for Aluminium Casting Services

Selecting the right vendor for aluminium metal casting is a critical decision that impacts project success, product quality, and cost-efficiency. A thorough evaluation process should consider several key factors:

- Technical Expertise and Experience: Assess the vendor's years of service in aluminium metal casting, their engineering capabilities, and their understanding of specific casting processes (e.g., green sand metal casting, aluminum die casting, permanent mold). Look for a track record of handling complex geometries and challenging alloy specifications.

- Quality Certifications and Standards: Verify compliance with international quality management systems such as ISO 9001, and material-specific standards like ASTM B26 for aluminium alloy for casting. Certifications for specific industries (e.g., IATF 16949 for automotive, AS9100 for aerospace) are also indicators of strong quality control.

- In-house Capabilities: A comprehensive vendor will offer end-to-end solutions, including mold design, casting, heat treatment, CNC machining, surface finishing, and NDT. This streamlines the supply chain and ensures consistent quality.

- Technology and Equipment: Evaluate the modernity of their casting equipment, automation levels, and their use of advanced simulation software for process optimization. State-of-the-art technology often translates to higher precision and fewer defects.

- Customer Support and Communication: Responsive communication, clear project management, and a willingness to collaborate on design for manufacturability (DFM) are crucial for successful partnerships. Review customer feedback and references.

- Scalability and Lead Time: Determine if the vendor can meet your volume requirements, from prototyping to mass production, and if their lead times align with your project schedules. Inquire about their fulfillment details and capacity planning.

- Cost-Effectiveness and Value: Beyond the initial quote, consider the total cost of ownership, including quality, potential rework, and logistical efficiencies. A competitive price combined with high quality offers the best value.

Engaging with a vendor that demonstrates a strong commitment to these principles ensures a reliable supply of high-quality metal castings that meet stringent performance criteria.

Customized Solutions for Aluminium Castings

In many B2B scenarios, off-the-shelf components are insufficient. Specialized requirements for dimensions, material properties, or functional integration necessitate customized aluminium metal casting solutions. Our expertise lies in collaborating closely with clients to develop bespoke metal castings that precisely fit their unique application needs.

- Alloy Selection and Development: Beyond standard alloys, we can work to specify or even custom-blend aluminium alloy for casting to achieve specific mechanical properties, corrosion resistance, or thermal performance characteristics.

- Complex Geometry and Design Optimization: Leveraging advanced CAD/CAM and casting simulation software, we optimize designs for manufacturability, ensuring intricate components can be cast with precision and minimal defects. This includes optimizing gating systems and riser placement.

- Integrated Manufacturing Processes: Custom solutions often combine casting with other processes such as specialized forging for critical areas or high-precision CNC machining for tight tolerances and surface finishes not achievable through casting alone. We can also integrate secondary operations like surface treatments (e.g., anodizing, powder coating, plating) and assembly.

- Tailored Testing and Quality Control: For critical applications, customized inspection protocols, including specific NDT methods (e.g., ultrasonic testing, eddy current), fatigue testing, or hydrostatic pressure testing, can be implemented to meet stringent industry standards and client performance benchmarks.

- Prototyping and Low-Volume Production: We support initial product development with rapid prototyping and offer flexible production capabilities for low-volume, highly specialized runs, allowing for iterative design improvements before scaling to mass production.

This tailored approach ensures that the final aluminium metal casting product not only meets functional requirements but also integrates seamlessly into the client's broader system, offering long-term reliability and performance.

Application Case Studies

Real-world applications demonstrate the tangible benefits and reliability of high-quality aluminium metal casting. Our experience and commitment to delivering superior metal castings are reflected in our successful collaborations.

Case Study 1: High-Pressure Pump Housing for Water Treatment

A leading industrial pump manufacturer required a lightweight, corrosion-resistant housing for a new line of high-pressure water treatment pumps. Their previous design, using a heavier cast iron, faced issues with excessive weight for installation and susceptibility to pitting corrosion in chlorinated water.

Solution: We proposed an A356-T6 aluminium alloy for casting produced via permanent mold casting, followed by precision CNC machining. The design was optimized for flow dynamics and structural integrity under 10 bar operating pressure.

Results: The new aluminium housing resulted in a 65% weight reduction, significantly easing installation and reducing shipping costs. Rigorous testing confirmed superior corrosion resistance, extending the product's service life by an estimated 50% compared to the previous design. Customer feedback highlighted improved pump efficiency and reduced long-term maintenance needs.

Case Study 2: Automotive Structural Component via Aluminum Die Casting

An automotive Tier 1 supplier needed a complex, thin-walled structural bracket for an electric vehicle chassis. The primary challenges were achieving tight dimensional tolerances, a high strength-to-weight ratio, and cost-effective mass production.

Solution: We utilized advanced aluminum die casting with a proprietary A380 alloy variant, employing sophisticated simulation tools to optimize die design and injection parameters. Post-casting, components underwent specific heat treatment and robotic trimming.

Results: The project delivered an ultra-lightweight component meeting stringent structural requirements while maintaining a highly competitive unit cost. Dimensional accuracy (within ±0.15mm) was consistently achieved over millions of units. The rapid cycle times inherent to aluminum die casting ensured on-time delivery for the vehicle's production schedule. This component contributed to the vehicle's enhanced range and safety ratings.

Trust and Transparency: FAQ, Lead Times, Warranty, and Support

Building trust with our B2B partners is paramount. We believe in transparency and providing comprehensive support throughout the entire engagement, from inquiry to post-delivery.

Frequently Asked Questions (FAQ)

Q: What are the typical lead times for custom aluminium metal casting projects?

A: Lead times vary significantly based on complexity, chosen casting method, and order volume. For new tooling and prototypes, lead times can range from 4-8 weeks. Production runs typically follow 3-6 weeks after initial sample approval. We provide detailed timelines upon project scope definition.

Q: What quality certifications do you hold?

A: We are ISO 9001 certified, ensuring stringent quality management systems are in place across all our operations. Our processes adhere to relevant ASTM, ANSI, and EN standards for materials and casting practices. Specific product certifications are provided as required.

Q: Can you work with proprietary aluminium alloy for casting?

A: Yes, we have extensive experience working with a wide range of standard and proprietary aluminium alloys. Our metallurgical team can provide guidance on material selection or assist in developing specific alloy compositions to meet unique performance criteria.

Q: What is your typical order fulfillment process?

A: Our fulfillment process begins with an initial consultation and quotation, followed by design review and tooling development. Once samples are approved, production is scheduled, followed by rigorous quality control, secure packaging, and logistics management to ensure on-time delivery.

Warranty Commitments

All our metal castings are manufactured to the highest standards and come with a comprehensive warranty against defects in material and workmanship. The specific terms of the warranty are outlined in our sales agreements and are typically for a period of 12 to 24 months from the date of shipment, ensuring peace of mind for our clients.

Customer Support and After-Sales Service

Our commitment extends beyond delivery. We provide dedicated customer support to address any post-purchase inquiries, technical assistance, or performance evaluations. Our engineering team is available for consultation, troubleshooting, and continuous improvement initiatives. We ensure that our partners receive prompt and effective assistance throughout the entire lifecycle of our aluminium metal casting components.

References

- ASM International. (2009). ASM Handbook Vol. 15: Casting. Materials Park, OH: ASM International.

- Davis, J. R. (Ed.). (1993). Aluminum and Aluminum Alloys. Materials Park, OH: ASM International.

- Modern Casting Magazine. (Various Issues). American Foundry Society.

- Society of Automotive Engineers (SAE) International. (Various Standards for Aluminum Alloys and Castings).

- ISO 9001:2015 - Quality management systems - Requirements.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025