Mobile:+86-311-808-126-83

Email:info@ydcastings.com

High-Quality 5 Inch End Cap for Optimal Pipe Sealing and Durability in Various Applications

Understanding the Importance of a 5% 20 Inch End Cap in Pipeline Systems

In the realm of engineering and industrial applications, pipeline systems play a crucial role in the transport of various fluids, gases, and materials. These systems rely on numerous components to ensure efficient flow control, safety, and operational effectiveness. Among these components, the end cap is a significant element that often goes unnoticed, yet it serves vital functions in the integrity of pipeline systems. Specifically, the 5% 20 inch end cap is a fitting that possesses unique characteristics and roles in various applications.

An end cap is a type of fitting that seals the end of a pipe or tube, serving multiple purposes. These caps can be part of a temporary solution during installation or act as a permanent closure in a pipeline system. The 5% 20 inch designation refers to the specific size and pressure rating of the end cap, which indicates its compatibility with a 20-inch diameter pipeline and a pressure tolerance of 5%.

Key Functions of the 5% 20 Inch End Cap

1. Pressure Regulation The 5% pressure rating denotes that the end cap is designed to withstand relatively high pressure without deforming or leaking. This is crucial in industries such as oil and gas, where pipelines must bear the pressure of transporting volatile substances. A reliable end cap ensures that the system can maintain its integrity under pressure, preventing leaks that could result in hazardous situations.

2. Pipeline Maintenance In many cases, pipeline maintenance requires sections of the line to be isolated for repairs or inspections. The use of a 5% 20 inch end cap allows workers to safely seal the pipeline at one end, ensuring that the liquid or gas within the system does not escape and cause spills or exposure to harmful substances. By securely capping the end of the pipe, maintenance can proceed safely and efficiently.

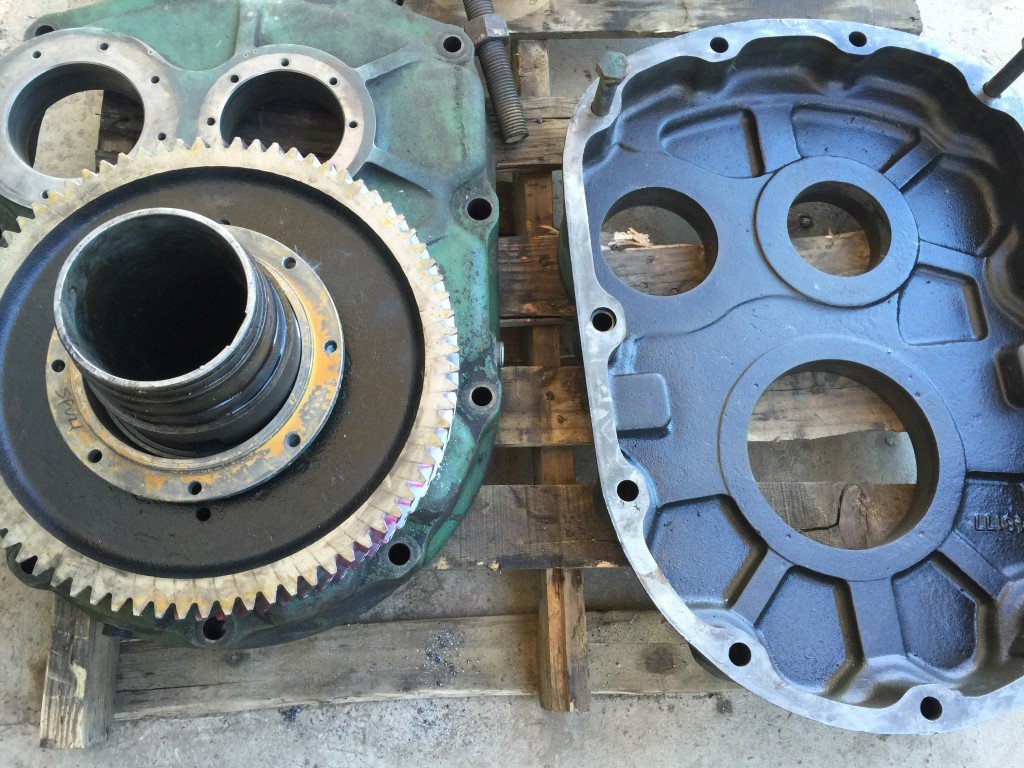

5 inch end cap

3. System Integrity The end cap contributes to the overall structural integrity of a pipeline. By providing a sealed closure, it minimizes the likelihood of environmental factors, such as dirt, debris, or moisture, entering the pipeline. This helps maintain the quality of the transported medium and prevents contamination, which is especially important in food and pharmaceutical industries.

4. Design Versatility The design of the 5% 20 inch end cap is versatile, allowing it to be used in various applications across multiple industries. Whether in fluid transport, wastewater management, or industrial manufacturing, having a reliable end cap that meets specific size and pressure requirements is essential for smooth operation.

Selection and Installation Considerations

When selecting a 5% 20 inch end cap, several factors need to be considered. The material of the cap is crucial, as it must be compatible with the fluid or gas being transported, as well as resistant to corrosion and wear. Additionally, the installation of the end cap should follow industry standards to ensure that the system is secure, which includes proper welding or threading techniques depending on the type of piping system in use.

Properly integrating a 5% 20 inch end cap into a pipeline system leads to enhanced safety and efficiency. It is a testament to the engineering principles that prioritize the functionality of industrial applications. Understanding the roles, applications, and considerations surrounding such components can lead to better decision-making when designing or maintaining pipeline systems.

In conclusion, while often overlooked, the 5% 20 inch end cap performs essential functions that contribute to the reliability and safety of pipeline systems. Ensuring that the right end caps are selected and installed can lead to increased operational efficiency and reduced risks within various industrial applications. Thus, investing attention and resources into this small yet significant component can lead to substantial benefits in the long run.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025