Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring Various Methods of Metal Casting Techniques for Enhanced Production Efficiency and Quality

Types of Metal Casting Processes

Metal casting is a fundamental manufacturing process where molten metal is poured into a mold to create a desired shape. This method is widely used in various industries due to its versatility and efficiency. There are several key types of metal casting processes, each with unique characteristics, advantages, and applications.

1. Sand Casting

One of the most common casting processes is sand casting. This technique uses sand as the primary mold material. The process begins with the creation of a pattern, often made of metal or plastic, which is then embedded in sand mixed with a binder. Once the pattern is removed, the cavity left behind is filled with molten metal. After solidification, the sand mold is broken away to reveal the final product. Sand casting is highly regarded for its ability to produce complex shapes and large components, making it ideal for manufacturing engine blocks, housings, and other heavy machinery components.

Investment casting, also known as lost-wax casting, is another popular method characterized by its ability to achieve high precision and excellent surface finishes. The process involves creating a wax pattern that is coated with a ceramic material. Once the ceramic hardens, the wax is melted away, leaving a hollow mold. Molten metal is then poured into the mold, solidifying into the desired shape. Investment casting is commonly used for intricate parts in aerospace, medical devices, and jewelry, where tight tolerances are crucial.

3. Die Casting

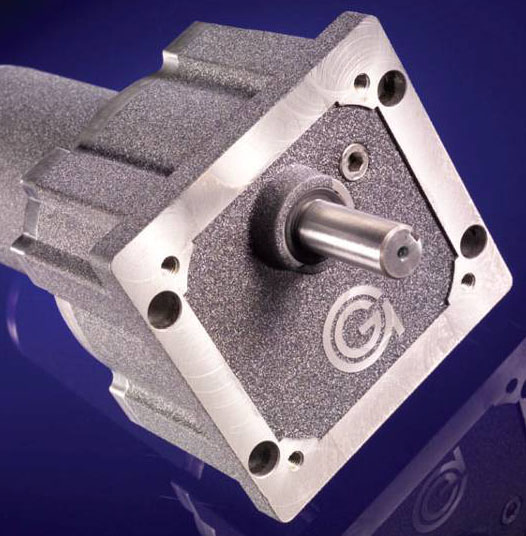

types of metal casting processes

Die casting is a highly efficient process used primarily for metals with a low melting point, such as aluminum, zinc, and magnesium. In this method, molten metal is injected into a steel die under high pressure. This technique allows for high-volume production with excellent dimensional accuracy and surface finish. Die casting is widely used in making automotive components, electronic housings, and consumer products due to its ability to produce parts that require minimal machining.

4. Permanent Mold Casting

Permanent mold casting is similar to die casting but involves the use of reusable molds, typically made of metal. This process allows for faster cooling of the metal and can result in improved mechanical properties. The molds are preheated before pouring, which helps in achieving finer details and surface quality. This method is often used for producing medium-sized parts in applications such as automotive and industrial machinery.

5. Continuous Casting

Continuous casting is a modern process primarily used for manufacturing metal shapes such as slabs, billets, or blooms. In this method, molten metal is poured into a continuous casting machine where it solidifies as it is drawn through a mold, creating a continuous length of material. This process significantly reduces waste and energy consumption and is widely employed in the steel industry to produce semi-finished products for further processing.

Conclusion

Metal casting encompasses a variety of processes, each tailored to meet specific industrial needs. From the traditional sand casting to the advanced techniques like investment and die casting, the ability to create complex shapes and intricate designs makes casting an essential part of modern manufacturing. As technology advances, innovations in materials and process efficiencies will continue to evolve, further expanding the applications and benefits of metal casting in various industries. Understanding the different types of casting processes ensures that manufacturers can choose the most suitable method for their specific requirements, leading to improved productivity and product quality.

-

What Makes Stainless Steel Pump Casting Essential for Modern Industries?NewsJul.14,2025

-

Revolutionize Your Engine Maintenance with Premium Aluminum and Cast Iron ComponentsNewsJul.14,2025

-

Precision Flow Engineering Starts with the Right Pump ComponentsNewsJul.14,2025

-

Maximize Efficiency: Explore Reliable Containment and Crop SolutionsNewsJul.14,2025

-

Discover Superior Performance with Advanced Turbo ComponentsNewsJul.14,2025

-

Boost Fluid Dynamics with Precision-Engineered Pump ComponentsNewsJul.14,2025