Mobile:+86-311-808-126-83

Email:info@ydcastings.com

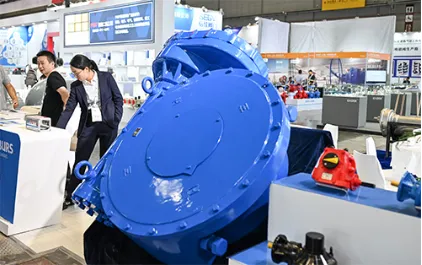

Exploring Various Impeller Designs and Their Applications in Fluid Dynamics Systems

Understanding Different Types of Impellers

Impellers are essential components used in various mechanical systems, especially in pumps and turbines. They are designed to impart kinetic energy to the fluid, allowing it to flow through a system efficiently. The type of impeller selected can significantly influence the performance, efficiency, and suitability of the equipment for specific applications. In this article, we will explore the different types of impellers, their functions, and their typical applications.

1. Radial Impellers

Radial impellers are characterized by blades that extend outward from the center, resembling a wheel. They are widely used in centrifugal pumps and are designed to move fluid outward from the impeller's axis. This design allows for a high flow rate and is suitable for applications requiring significant lifting capacity. Radial impellers are commonly found in water supply, irrigation, and industrial processes.

In contrast to radial impellers, axial impellers have blades that are oriented parallel to the axis of rotation. They are designed to move fluid along the impeller’s axis in a direction that is parallel to the axis of rotation. This design maximizes the fluid flow rate while minimizing pressure rise, making them ideal for applications where high flow at low pressure is required, such as in marine propellers, HVAC systems, and some types of agricultural equipment.

3. Mixed-Flow Impellers

Mixed-flow impellers combine features of both radial and axial designs. They allow fluid to flow both axially and radially, providing a compromise between high flow rates and moderate pressure increase. Due to their versatility, mixed-flow impellers are commonly used in applications like sewage treatment, chemical processing, and various industrial pumps where a balance between flow rate and pressure is desired.

different types of impellers

4. Open Impellers

Open impellers consist of blades without any shrouds or casings, providing a simple and effective design for applications involving clear liquids or fluids with little to no solids. Their open structure offers ease of cleaning and maintenance, making them ideal for food processing, pharmaceuticals, and other sanitary applications. However, open impellers may struggle with efficiency when handling more viscous fluids or mixtures with solids.

5. Closed Impellers

Closed impellers, on the other hand, are enclosed within a casing, which helps to maintain higher efficiency, especially when handling viscous fluids or those containing solids. The enclosed design minimizes fluid turbulence and enhances the pressure increase, making closed impellers particularly suitable for industrial pumps, chemical processing, and wastewater management where flow rates must be controlled effectively.

6. Vortex Impellers

Vortex impellers are designed to create a swirling motion in the fluid, allowing them to handle solids and debris more effectively than traditional designs. Due to their unique flow patterns, vortex impellers are commonly used in applications like sewage treatment, slurry pumps, and certain chemical processes where large particles must be handled without causing blockages.

Conclusion

Selecting the appropriate type of impeller is critical to the efficiency and effectiveness of a system. Each design—radial, axial, mixed-flow, open, closed, and vortex—serves unique functions and is suited to specific applications. By understanding these differences, engineers and technicians can make informed decisions that enhance system performance, reduce energy consumption, and meet operational requirements. As technology advances and applications diversify, the innovation of impeller designs will continue to play a crucial role in the development of more efficient fluid handling systems.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025