Mobile:+86-311-808-126-83

Email:info@ydcastings.com

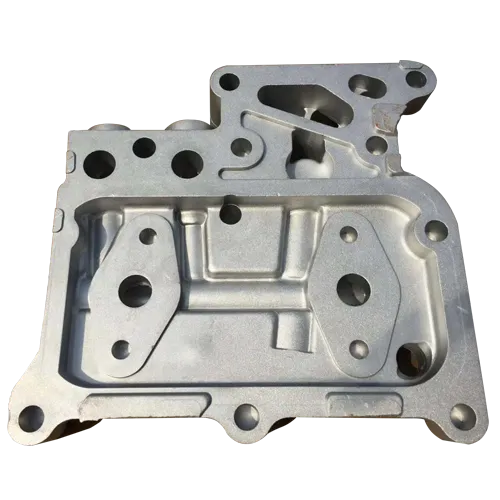

Exploring the Techniques and Advantages of High-Quality JIS Casting in Manufacturing Processes

The Art and Science of JIS Casting A Comprehensive Overview

JIS casting, or Japanese Industrial Standards casting, is a significant aspect of manufacturing that has gained prominence for its precision and quality. The JIS standards were established to ensure the quality and interoperability of industrial components, contributing to Japan's reputation for excellence in engineering and manufacturing. This article explores the principles, advantages, and applications of JIS casting.

What is JIS Casting?

JIS casting refers to the process of producing metal parts by pouring molten metal into molds that conform to specific standards set forth by the Japanese Industrial Standards. These standards cover various aspects of casting, including materials, tolerances, and testing methods. The standardized approach ensures that components produced are reliable and meet stringent quality checks, which is crucial in industries where safety and durability are paramount.

The JIS Standards Framework

The JIS standards for casting include a wide range of specifications for different materials, such as cast iron, aluminum, and steel. Each material has particular characteristics that influence the casting process, including melting point, fluidity, and cooling rates. The standards include guidelines on the types of defects that can occur during the casting process and how to mitigate them. This comprehensive framework serves as a foundation for manufacturers to create high-quality cast components consistently.

Advantages of JIS Casting

1. Quality Assurance One of the most significant advantages of JIS casting is its strong emphasis on quality control. Manufacturers adhere to rigorous testing and inspection protocols, ensuring that each component meets the required specifications. This level of quality assurance can lead to enhanced durability and reliability of the final products.

jis casting

2. Interchangeability The JIS standards facilitate the production of interchangeable parts. This interchangeability is crucial in industries such as automotive and aerospace, where components must fit precisely with others. It reduces the risk of assembly errors and improves overall efficiency.

3. Innovation and Adaptability The JIS framework encourages continuous improvement and innovation in casting techniques. Manufacturers are motivated to adopt new technologies, such as computer-aided design (CAD) and advanced molding processes, to enhance the quality and efficiency of casting. As a result, the industry is constantly evolving to meet changing market demands.

4. Environmental Considerations Many JIS casting manufacturers are adopting more environmentally friendly practices. These include recycling scrap materials and minimizing waste during the casting process. The emphasis on sustainability aligns with global trends and regulatory requirements, making JIS casting a more appealing option for environmentally conscious consumers.

Applications of JIS Casting

JIS casting finds applications across various industries, reflecting its versatility and reliability. In the automotive sector, it is used to produce engine blocks, transmission housings, and many other critical components. The aerospace industry also benefits from JIS casting, as it aids in creating lightweight yet strong parts necessary for aviation.

Furthermore, JIS casting is vital in the manufacturing of industrial machinery and equipment, where precision and reliability are non-negotiable. From pumps and valves to structural components, the use of JIS casting ensures that these parts can withstand the rigors of their operational environments.

Conclusion

In conclusion, JIS casting represents a blend of art and science, rooted in Japan’s commitment to quality and precision manufacturing. By adhering to strict standards, JIS casting plays an essential role in multiple industries, promoting innovation, sustainability, and most importantly, quality assurance. As global manufacturing continues to evolve, the principles and practices of JIS casting will remain pivotal in shaping the future of the industry.

-

Why Is Choosing the Right Motor Housing Critical for Engine Performance?NewsJul.18,2025

-

Which Impeller Types Best Optimize Your Pump’s Efficiency?NewsJul.18,2025

-

Optimize Maintenance Efficiency with Durable Oil Catch SolutionsNewsJul.18,2025

-

Maximize Pump Performance with Precision-Engineered ComponentsNewsJul.18,2025

-

Elevate Industrial Flow Systems with Precision-Engineered ComponentsNewsJul.18,2025

-

Boost Durability and Functionality with Precision Power CastingsNewsJul.18,2025