Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the Efficiency and Design Features of Single Impeller Pump Systems in Modern Applications

Understanding Single Impeller Pumps Function and Applications

Single impeller pumps are a crucial component in various industries, providing efficient fluid movement and control in diverse applications. With their simplicity and effectiveness, these pumps have become a preferred choice for many engineering and manufacturing processes. In this article, we will delve into the workings, design, advantages, and applications of single impeller pumps.

What is a Single Impeller Pump?

A single impeller pump, often referred to as a centrifugal pump, features a single rotating component known as the impeller. The impeller's role is to impart kinetic energy to the fluid, converting it into pressure energy as the fluid moves through the pump. As the impeller spins, it creates a low-pressure zone at its center, drawing in fluid from the inlet. This fluid is then expelled through the pump discharge, driven by the centrifugal force generated.

Design and Components

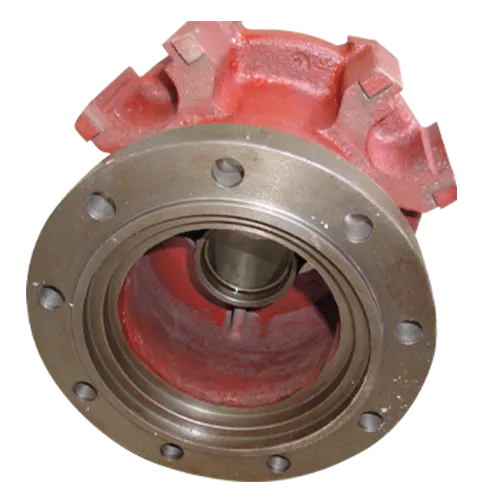

The design of a single impeller pump is relatively straightforward, yet highly effective. The primary components include the impeller, the volute casing, the inlet and outlet ports, and the drive mechanism. The impeller is typically constructed from stainless steel, plastic, or other corrosion-resistant materials to suit different fluid types and operating conditions.

The volute casing is designed to efficiently convert the velocity of the fluid into pressure, allowing for smooth flow downstream. Additionally, a single impeller pump often features mechanical seals to prevent leaks and protect the internal components from wear and tear.

Advantages of Single Impeller Pumps

single impeller

One of the most significant advantages of single impeller pumps is their simplicity. Their straightforward design allows for easy installation, maintenance, and operation. Furthermore, they are capable of handling a wide variety of fluids, including water, acids, and slurries, making them versatile for different industries.

Another advantage is their cost-effectiveness. Single impeller pumps tend to be more affordable than multi-impeller or positive displacement pumps, making them an attractive option for budget-conscious projects. They also offer a favorable power-to-flow ratio, ensuring efficient energy use during operation.

Applications

Single impeller pumps are used in a multitude of applications across various industries. In agricultural settings, they are utilized for irrigation to efficiently move water from sources to fields. In the chemical industry, these pumps assist in transferring various fluids, including corrosive chemicals and slurries, contributing to the efficient operation of processing plants.

In the municipal sector, single impeller pumps are essential for water supply and wastewater management systems. They help transport clean water to homes and businesses while also facilitating the treatment and disposal of wastewater. Similarly, these pumps find applications in HVAC systems for circulating water or coolant.

Conclusion

In conclusion, single impeller pumps are a vital technology that has proven beneficial in a wide range of applications. Their design simplicity, versatility, and cost-effectiveness make them an excellent choice for industries requiring reliable fluid movement. As technology continues to evolve, we can expect further innovations in pump design and efficiency, ensuring that single impeller pumps remain at the forefront of fluid handling solutions. Whether in agriculture, chemical processing, or municipal systems, these pumps will continue to play an essential role in maintaining operational efficiency and effectiveness.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025