Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the Design and Functionality of T31 Turbine Housing for Enhanced Performance

Understanding T31% Turbine Housing Technology and Applications

The T31% turbine housing represents a critical component in the design and functionality of modern turbochargers and gas turbines. In the ever-evolving field of aerospace and automotive engineering, the importance of efficient turbine housing cannot be overstated. It serves not only as a protective casing but also plays a pivotal role in optimizing performance, enhancing durability, and improving fuel efficiency.

At its core, the turbine housing is designed to guide the exhaust gases from the engine to the turbine. The T31% designation often refers to a specific design or performance characteristic related to the housing's ability to manage these gases effectively. The percentage denotes the efficiency rating, indicating how well the turbine housing converts exhaust energy into useful work, which is vital for maximizing energy recovery from exhaust gases.

Understanding T31% Turbine Housing Technology and Applications

Material selection plays a crucial role in the effectiveness of the T31% turbine housing. Typically, high-temperature alloys or specialized composites are used to withstand the extreme heat generated during combustion. These materials not only need to endure thermal stresses but must also resist oxidation and wear over time. The latest developments in metallurgy and material science have yielded lighter yet stronger options, allowing for significant weight reductions in rotor assemblies, which improve overall engine performance.

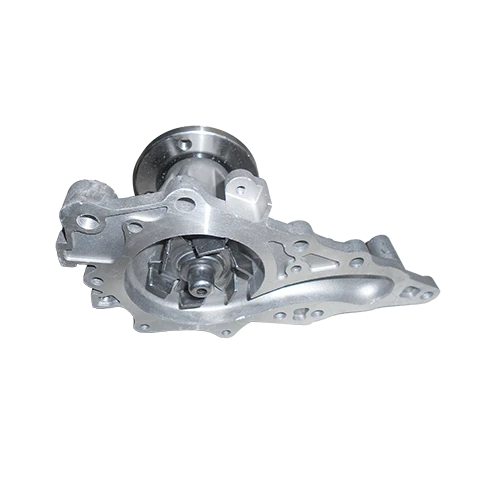

t31 turbine housing

Another critical factor in the design of the T31% turbine housing is thermal efficiency. In many applications, especially in turbocharged engines, managing the heat generated is paramount. An inefficient housing can cause excessive heat buildup, which can lead to engine knock, increased emissions, and even catastrophic failures. Advanced cooling channels and heat shielding technologies are often integrated into the design to mitigate these risks, ensuring that the turbine housing maintains a stable operating temperature.

In addition to performance benefits, the T31% turbine housing can also contribute to emissions control. As the automotive and aerospace industries increasingly face stringent environmental regulations, the ability to optimize exhaust flow through efficient turbine housing designs can help manufacturers meet these standards. By ensuring that exhaust gases are effectively managed and reduced in temperature and velocity, the T31% turbine housing helps in minimizing the environmental footprint of modern engines.

The versatility of the T31% turbine housing extends beyond automotive applications. In aerospace, for instance, it translates into improved performance and greater reliability for jet engines and auxiliary power units (APUs). Additionally, its applications in industrial settings, such as power generation and marine engines, further underscore the critical importance of this component in a variety of high-performance systems.

In conclusion, the T31% turbine housing is a marvel of modern engineering that embodies the continued pursuit of efficiency, performance, and sustainability across multiple industries. As technology advances, so too will the designs and materials used in turbine housing, paving the way for even more innovations in energy management and performance optimization. Whether in a sports car, a commercial jet, or an industrial generator, the significance of a well-designed turbine housing cannot be overlooked.

-

What Makes Stainless Steel Pump Casting Essential for Modern Industries?NewsJul.14,2025

-

Revolutionize Your Engine Maintenance with Premium Aluminum and Cast Iron ComponentsNewsJul.14,2025

-

Precision Flow Engineering Starts with the Right Pump ComponentsNewsJul.14,2025

-

Maximize Efficiency: Explore Reliable Containment and Crop SolutionsNewsJul.14,2025

-

Discover Superior Performance with Advanced Turbo ComponentsNewsJul.14,2025

-

Boost Fluid Dynamics with Precision-Engineered Pump ComponentsNewsJul.14,2025