Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the Benefits of Partnering with a Leading Aluminum Die Casting Manufacturer for Quality Solutions

Understanding Aluminum Die Casting Companies Innovation and Efficiency in Manufacturing

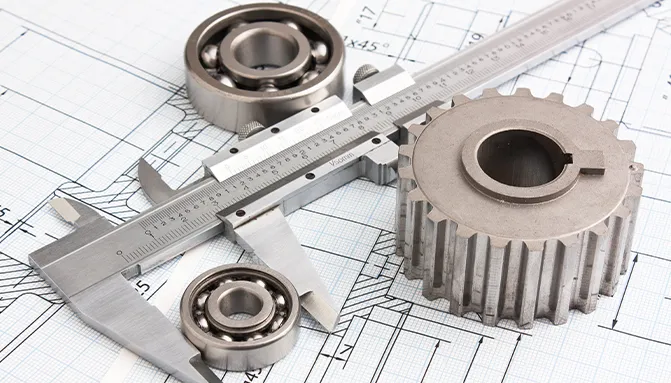

Aluminum die casting is a highly efficient manufacturing process that produces complex metal components with excellent precision and surface finish. This technique is particularly favored in industries like automotive, aerospace, electronics, and consumer goods due to its ability to create lightweight yet durable parts. As businesses increasingly seek ways to enhance productivity and reduce production costs, aluminum die casting companies have emerged as key players in the manufacturing landscape.

Understanding Aluminum Die Casting Companies Innovation and Efficiency in Manufacturing

One of the primary benefits of working with aluminum die casting companies is their expertise in developing customized solutions tailored to the specific needs of clients. Companies in this sector invest significantly in research and development to keep up with the latest technological advancements. They utilize computer-aided design (CAD) software and simulation tools to optimize mold designs and production processes, ensuring that every component meets stringent industry standards. Moreover, many aluminum die casting companies also offer additional services such as machining, surface finishing, and assembly, providing a one-stop solution for manufacturers.

aluminum die casting company

Sustainability is another critical aspect driving the growth of aluminum die casting companies. As environmental concerns continue to rise, these companies are adopting more sustainable practices, such as using recycled aluminum in their processes. This not only reduces energy consumption and waste but also decreases the carbon footprint associated with metal production. By promoting recycling and using eco-friendly methods, aluminum die casting companies are positioning themselves as responsible leaders in the manufacturing sector.

Moreover, the versatility of aluminum die casting allows it to meet the diverse demands of various industries. In the automotive sector, for instance, aluminum castings are used for engine blocks, transmission housings, and various other components, contributing to lighter vehicles that enhance fuel efficiency. In the aerospace industry, the strength-to-weight ratio of aluminum makes it an ideal choice for aircraft parts, ensuring safety while minimizing weight. The electrical and electronics industries also benefit from aluminum die casting, using it for housing and structural components that require excellent thermal conductivity and electromagnetic interference shielding.

As the market for aluminum die casting continues to expand, companies are also focusing on enhancing their production capabilities. Automation and robotics are becoming increasingly common in manufacturing processes, improving efficiency and reducing labor costs. Advanced technologies, such as artificial intelligence and machine learning, are being integrated into operations to predict maintenance needs, optimize production schedules, and enhance quality control.

In conclusion, aluminum die casting companies play an essential role in modern manufacturing by delivering high-quality, cost-effective, and sustainable solutions across various industries. Their commitment to innovation, coupled with a focus on customer satisfaction, positions them as vital partners for businesses looking to thrive in an increasingly competitive environment. As technology continues to advance, the future of aluminum die casting looks promising, with the potential for even greater efficiency and creativity in the production of complex components.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025