Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the Benefits and Techniques of Aluminium Casting Dies in Modern Manufacturing Processes

The Importance of Aluminium Casting Die in Modern Manufacturing

Aluminium casting die plays a pivotal role in the manufacturing industry, particularly in the production of complex shapes and components that are essential for various applications. Die casting is a technique that involves forcing molten aluminium into a precisely shaped mold, or die, allowing for high-volume production and a superior finish. As industries strive for efficiency and precision, understanding the significance of aluminium casting die becomes increasingly essential.

Advantages of Aluminium Die Casting

One of the primary advantages of using aluminium for die casting is its excellent fluidity. When it's melted, aluminium can flow into intricate mold designs, capturing fine details and producing components with tight tolerances. This characteristic is crucial for industries such as automotive and aerospace, where precision is paramount for safety and performance.

Moreover, aluminium is lightweight yet strong, making it an ideal choice for applications where weight reduction is critical. For instance, companies in the automotive sector have shifted towards aluminium die casting to create lighter vehicles, improving fuel efficiency without compromising structural integrity. This trend is also reflected in the aerospace industry, where reducing weight can enhance flight performance and reduce emissions.

The Casting Process

The process of aluminium die casting involves several stages, starting with the design of the die itself. Engineers utilize advanced computer-aided design (CAD) software to create highly detailed models that maximize the efficiency of the casting process. Once the design is finalized, the die is manufactured, typically from high-strength steel or iron, to withstand the intense pressures and temperatures involved.

After preparing the die, molten aluminium is injected into it under high pressure. This process allows the aluminium to fill every corner of the die, forming components that are not only precise but also exhibit a smooth surface finish. Once cooled, the die opens, and the finished part is ejected. This rapid cycle time and the ability to create complex geometries make aluminium die casting a cost-effective solution for mass production.

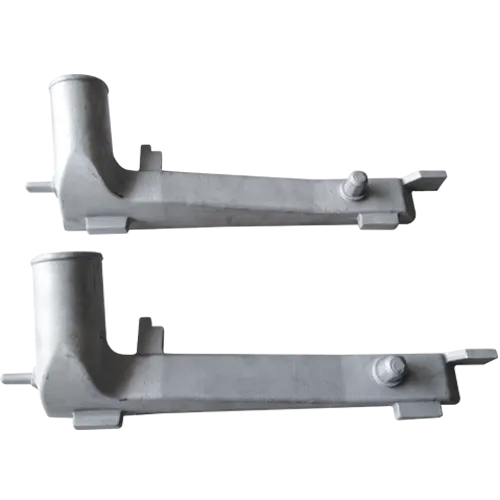

aluminium casting die

Applications of Aluminium Die Casting

Aluminium die casting finds applications across various industries. In the automotive sector, it is used to manufacture engine blocks, transmission housings, and other components that require durability and precision. In the electronics sector, die-cast aluminium housings provide a robust solution for protecting sensitive electronic components. Similarly, in the furniture industry, aluminium die casting is used for decorative items and functional hardware.

The versatility of aluminium die casting also extends to the production of consumer goods, such as kitchenware and sporting equipment. Manufacturers appreciate the ability to create intricate designs that enhance both function and aesthetic appeal.

The Future of Aluminium Die Casting

As technology advances, the future of aluminium die casting looks promising. Innovations in processes, such as the development of better alloys and enhanced die materials, are expected to further improve the efficiency and quality of cast parts. Additionally, the integration of automation and digital technologies in manufacturing is streamlining production processes, reducing waste, and improving turnaround times.

Sustainability is another key focus. The aluminium casting industry is actively exploring ways to minimize its environmental impact by recycling scrap material and reducing energy consumption. The trend towards greener manufacturing practices aligns with global goals to foster sustainable production and consumption patterns.

Conclusion

In conclusion, aluminium casting die is a cornerstone of modern manufacturing, offering a combination of precision, efficiency, and versatility. Its applications span numerous industries, making it an indispensable process for producing high-quality components. As advancements continue to transform the landscape of manufacturing, aluminium die casting remains at the forefront, adapting to meet the evolving needs of tomorrow’s market.

-

What Makes Stainless Steel Pump Casting Essential for Modern Industries?NewsJul.14,2025

-

Revolutionize Your Engine Maintenance with Premium Aluminum and Cast Iron ComponentsNewsJul.14,2025

-

Precision Flow Engineering Starts with the Right Pump ComponentsNewsJul.14,2025

-

Maximize Efficiency: Explore Reliable Containment and Crop SolutionsNewsJul.14,2025

-

Discover Superior Performance with Advanced Turbo ComponentsNewsJul.14,2025

-

Boost Fluid Dynamics with Precision-Engineered Pump ComponentsNewsJul.14,2025