Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the Benefits and Applications of CF8 Casting in Modern Manufacturing Techniques

The Art and Science of CF8 Casting

In the world of metalworking and manufacturing, casting processes play a pivotal role in creating components that are essential for various industries, from automotive and aerospace to construction and machinery. One particular type of casting that has garnered attention due to its excellent mechanical properties and corrosion resistance is CF8 casting.

Understanding CF8 Casting

CF8 is a type of stainless steel, specifically classified as austenitic, which contains approximately 18% chromium and 8% nickel. This composition imparts a range of desirable properties, making it suitable for several applications. The term CF denotes its classification under the ASTM A351 specification, which is commonly used for casting stainless steel in various forms. CF8's unique traits are exceptionally valuable in environments prone to oxidation and corrosion.

The casting process of CF8 typically involves preparing a wax or sand mold. The molten metal is poured into the mold, allowing it to cool and solidify. This process not only shapes the component but also enhances its mechanical integrity. Once cooled, the casting is often subjected to heat treatments that further improve its performance, riveting its relevance in high-demand applications.

Benefits of CF8 Casting

One of the most prominent advantages of CF8 casting is its outstanding corrosion resistance. The chromium content in CF8 provides a protective oxide layer on the steel surface, which helps prevent rust and deterioration when exposed to various corrosive elements, such as moisture and chemicals. This property makes CF8 an excellent choice for components used in marine environments, chemical processing plants, and food processing facilities.

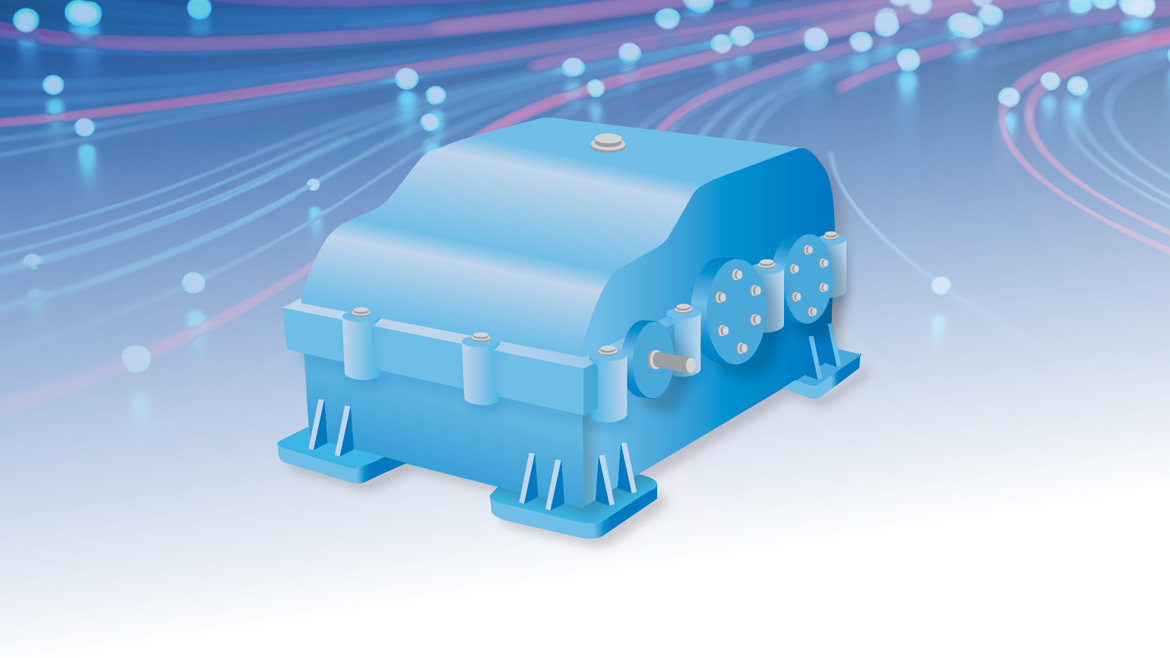

cf8 casting

In addition to its corrosion resistance, CF8 also exhibits good mechanical strength and toughness. The austenitic structure contributes to its ability to withstand extreme temperatures, making it suitable for applications requiring heat resistance. This is crucial for industries like aerospace, where components are often subjected to significant thermal stresses.

Another benefit of CF8 casting is its outstanding ability to be machined and formed. Unlike some stainless steels that can be challenging to work with due to their hardness, CF8 can be easily shaped and refined, allowing for precise fabrication of intricate parts. This machinability is particularly advantageous for manufacturers looking to produce complex components efficiently.

Applications of CF8 Casting

Given its advantageous properties, CF8 casting is widely used across numerous sectors. In the chemical industry, it is commonly employed to fabricate valves, pumps, and fittings that need to handle aggressive substances safely. In the food processing sector, CF8 components ensure hygiene and safety while resisting corrosion from cleaning agents and other substances.

The marine industry also relies on CF8 for constructing pumps and marine hardware due to its ability to withstand the harsh effects of saltwater. Furthermore, in the aerospace sector, CF8 casting finds applications in components that require robustness coupled with resistance to extreme conditions.

Conclusion

CF8 casting represents a harmonious blend of art and science in the field of metallurgy. Its unique properties, including exceptional corrosion resistance, mechanical strength, and machinability, make it an invaluable choice in various industrial applications. As technology continues to advance and industries evolve, the relevance of CF8 casting is expected to grow, leading to enhanced designs and more efficient manufacturing processes. As we embrace the future, the legacy of CF8 will undoubtedly continue to shape the landscape of metalworking and its applications.

-

What Makes Stainless Steel Pump Casting Essential for Modern Industries?NewsJul.14,2025

-

Revolutionize Your Engine Maintenance with Premium Aluminum and Cast Iron ComponentsNewsJul.14,2025

-

Precision Flow Engineering Starts with the Right Pump ComponentsNewsJul.14,2025

-

Maximize Efficiency: Explore Reliable Containment and Crop SolutionsNewsJul.14,2025

-

Discover Superior Performance with Advanced Turbo ComponentsNewsJul.14,2025

-

Boost Fluid Dynamics with Precision-Engineered Pump ComponentsNewsJul.14,2025