Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the Benefits and Applications of 17-4 PH Investment Casting in Modern Manufacturing

The Significance of 17% 204 PH Stainless Steel in Investment Casting

Investment casting, also known as lost-wax casting, is a precision casting process that allows for the production of complex metal parts with excellent dimensional accuracy and surface finish. Among the various materials used in this process, 17% 204 PH stainless steel stands out due to its unique properties and advantages. This article explores the significance of 17% 204 PH stainless steel in investment casting and its applications in various industries.

Understanding 17% 204 PH Stainless Steel

The designation 17% 204 PH refers to a specific type of stainless steel alloy that contains approximately 17% chromium, along with nickel and other elements. PH stands for precipitation hardening, which means the steel can be hardened through a heat treatment process. This alloy is known for its excellent mechanical properties, corrosion resistance, and ability to retain strength at elevated temperatures, making it suitable for various high-performance applications.

Advantages in Investment Casting

1. Dimensional Accuracy One of the primary benefits of using 17% 204 PH in investment casting is its remarkable dimensional accuracy. The investment casting process creates intricate and precise components with minimal machining required, thus saving time and reducing costs.

2. Corrosion Resistance The high chromium content in 17% 204 PH stainless steel endows it with exceptional corrosion resistance, making it ideal for applications in environments where exposure to moisture, chemicals, or extreme conditions is a concern. This property ensures the longevity and reliability of components made from this alloy.

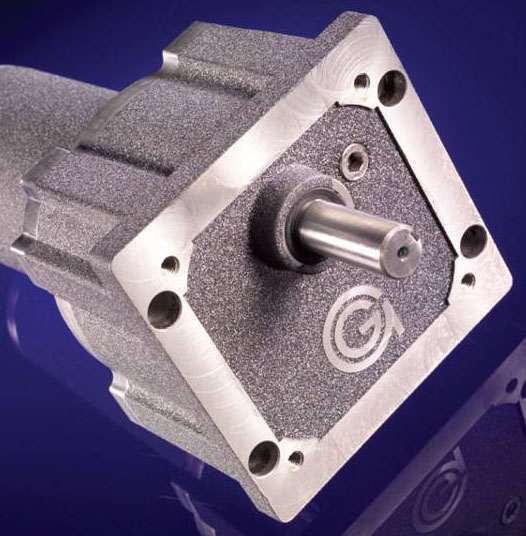

17 4 ph investment casting

3. High Strength and Hardness The ability to heat-treat 17% 204 PH stainless steel allows manufacturers to enhance its strength and hardness, providing substantial mechanical properties suitable for demanding applications. Components cast from this alloy can withstand high loads and stresses, making them suitable for industries requiring durable materials.

4. Versatility Suitable for various applications, 17% 204 PH stainless steel is used in industries such as aerospace, automotive, oil and gas, and medical devices. Its versatility in both mild and harsh environments allows for diverse use-cases, ranging from turbine blades to surgical instruments.

5. Excellent Surface Finish Investment casting with 17% 204 PH stainless steel results in components with superior surface finishes compared to traditional casting methods. This characteristic is particularly beneficial in applications where aesthetic appearance and smooth surfaces are critical.

Applications Across Industries

Due to its unique properties, 17% 204 PH stainless steel is employed in numerous industries. In aerospace, it is used for parts that require lightweight yet strong materials, such as brackets and frames. The automotive sector utilizes this alloy for various engine components, exhaust systems, and safety features. In the oil and gas industry, it is favored for valves and fittings that endure harsh operational environments. Medical equipment manufacturers also rely on 17% 204 PH due to its sterilization capability and resistance to bodily fluids.

Conclusion

17% 204 PH stainless steel represents a significant innovation in the realm of investment casting. Its combination of strength, corrosion resistance, and exceptional dimensional accuracy makes it an ideal choice for industries requiring high-performance components. As technology advances and industries continue to evolve, the demand for materials like 17% 204 PH stainless steel is likely to increase, paving the way for new applications and innovations. In an era where precision and reliability are paramount, the role of this remarkable alloy in investment casting is undeniably crucial.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025