Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring HEMI Engine Benefits and Innovations in Exhaust Manifold Design and Performance Optimization

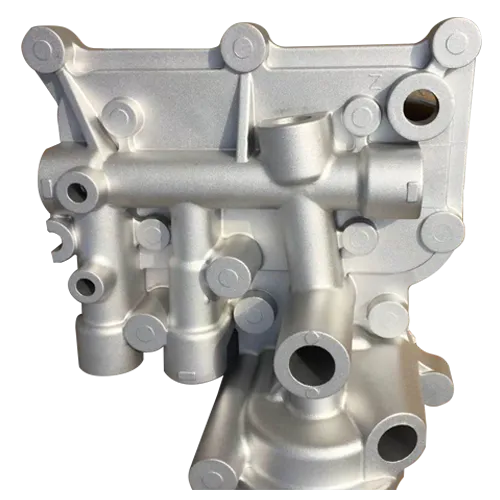

Understanding the Hemi Exhaust Manifold Design and Performance

The Hemi exhaust manifold is a crucial component in the engine design of vehicles, especially those that are equipped with the Hemi V8 engine. The term “Hemi” refers to the hemispherical design of the engine's combustion chamber, which allows for improved airflow and efficient combustion. The exhaust manifold, on the other hand, plays an essential role in directing exhaust gases from the engine to the exhaust system, ultimately influencing the engine's overall performance.

The Design of Hemi Exhaust Manifolds

Hemi exhaust manifolds are typically constructed from cast iron or stainless steel, materials chosen for their durability and heat resistance. The design of these manifolds is particularly important as it affects not just the emission of gases but also the engine’s performance, horsepower, and torque. The design often features a series of tubes that connect each exhaust port from the engine to the outlet, allowing for smooth evacuation of exhaust gases.

One of the distinctive features of Hemi exhaust manifolds is their compact design. Because of the 90-degree angle of the engine's configuration, the manifold must efficiently bundle the exhaust flow while minimizing backpressure. This is essential for improving performance, as excessive backpressure can lead to reduced engine efficiency, increased fuel consumption, and diminished power output.

Performance Enhancements

The effectiveness of the Hemi exhaust manifold can significantly impact the performance metrics of a vehicle. A well-designed manifold enhances exhaust flow, which allows the engine to breathe better, subsequently improving horsepower and torque across various RPM ranges. The increased efficiency in the expulsion of exhaust gases enables the engine to operate more smoothly, leading to enhanced throttle response.

hemi exhaust manifold

Performance enthusiasts often seek aftermarket upgrades to their Hemi exhaust manifolds. These aftermarket options frequently feature larger piping and optimized bends, allowing for even greater exhaust flow. Some designs incorporate features such as equal-length runners, which help in maintaining consistent pressure and temperature, further boosting performance.

The Role of Exhaust Manifolds in Emissions Control

In addition to performance, Hemi exhaust manifolds play a vital role in ensuring compliance with emissions regulations. As environmental standards become increasingly stringent, manufacturers are required to develop exhaust systems that minimize harmful emissions. The design of the exhaust manifold must work in sync with other components, such as catalytic converters and oxygen sensors, to ensure that the engine operates efficiently and within legal emissions limits.

Furthermore, modern advancements in technology have allowed for the integration of heat shields, thermal barriers, and tuned lengths within the exhaust manifold, all aimed at optimizing exhaust flow while reducing heat transfer to other engine components. This not only helps with emissions control but also contributes to engine longevity and reliability.

Conclusion

In summary, the Hemi exhaust manifold is a vital component that significantly affects engine performance and emissions control. Its unique design complements the Hemi engine's combustion characteristics, facilitating optimal exhaust flow and enhancing overall efficiency. With ongoing advancements in manufacturing materials and design techniques, both OEM and aftermarket options continue to evolve, offering vehicle owners various solutions to maximize their engine’s performance while adhering to emissions standards. Understanding the intricacies of Hemi exhaust manifolds can help automotive enthusiasts and everyday drivers alike appreciate the complexity and engineering behind modern internal combustion engines.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025