Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

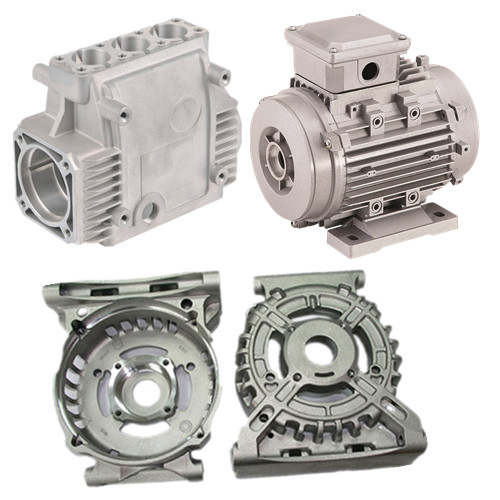

end cover

The Importance of End Covers in Modern Manufacturing

In the realm of modern manufacturing, where precision and efficiency play pivotal roles, attention to detail can make a significant difference. One often-overlooked, yet crucial component in various products is the end cover. An end cover serves as a protective barrier that encases the ends of a product or assembly, offering multiple benefits that enhance both functionality and longevity.

End covers are utilized across a wide range of industries, from automotive to electronics, and their designs can vary greatly depending on the application. Typically made from materials such as plastic, metal, or rubber, these covers are engineered to protect sensitive components from environmental factors such as dust, moisture, and mechanical damage. In the automotive sector, for example, end covers are essential for safeguarding electrical connectors and engine parts, ensuring they operate efficiently and reliably over time.

One of the primary purposes of an end cover is to provide protection. By shielding vulnerable components, end covers help prevent the accumulation of debris that can lead to malfunctions. In electronic devices, for instance, an end cover can prevent dust buildup on sensitive circuit boards, which can significantly extend the life of the device. Moreover, in scenarios where products are exposed to harsh chemicals or extreme weather conditions, the right end cover material can provide additional resistance, ensuring that the integrity of the components remains intact.

end cover

In addition to protection, end covers also contribute to the aesthetic appeal of a product. A well-designed end cover can enhance the overall appearance of an item, making it more visually appealing to consumers. Manufacturers are increasingly recognizing the importance of design elements, and end covers are no exception. Customizable end covers can incorporate branding, logos, or distinct color schemes, allowing companies to create a strong visual identity while also providing functional benefits.

Furthermore, end covers can play a vital role in safety. In industrial applications, exposed edges of machinery or components can pose hazards. Here, end covers create a barrier that minimizes the risk of accidents, protecting workers from sharp edges or moving parts. Ensuring safety in the workplace is a priority for any manufacturer, and the incorporation of end covers is a simple yet effective measure to mitigate risk.

Lastly, from a practical perspective, end covers can facilitate assembly and disassembly. In modular systems, for example, end covers can allow for straightforward access to internal components without damaging the product. This ease of access is particularly beneficial for maintenance and repairs, contributing to reduced downtime and improved operational efficiency.

In summary, end covers are far more than mere accessories; they are essential components that enhance protection, aesthetics, safety, and maintenance efficiency. As manufacturing continues to evolve, the importance of thoughtful design and functionality remains paramount. Whether you are in the automotive, electronics, or any other industry, paying attention to the details—like choosing the right end cover—can lead to better products and satisfied customers. As we move forward, the role of end covers will undoubtedly become even more significant in developing innovative and durable products that stand the test of time.

-

Superior Aluminum Castings in Automotive Engine PartsNewsAug.22,2025

-

Common Materials Used in Fan Housing ManufacturingNewsAug.22,2025

-

Symptoms of a Stuck Automobile Water Pump ImpellerNewsAug.22,2025

-

The Importance of Valve Castings in Water TreatmentNewsAug.22,2025

-

Welding Techniques for End Cap Stainless Steel FittingsNewsAug.22,2025

-

How to Install a Water Pump Connector ProperlyNewsAug.22,2025