Mobile:+86-311-808-126-83

Email:info@ydcastings.com

End Cap Solutions for MS Pipe Applications and Installations

Understanding End Caps for MS Pipes

In the world of industrial piping systems, certain components play a critical role in ensuring the integrity and functionality of the overall structure. Among these components, end caps, specifically for mild steel (MS) pipes, are essential when it comes to sealing the ends of the pipes for various applications. This article will delve into the significance, types, applications, advantages, and installation of end caps for MS pipes.

What Are MS Pipes?

Mild steel pipes are made from low carbon steel, which typically contains less than 0.3% carbon content. This composition grants them a unique combination of strength, ductility, and weldability, making them a popular choice in various construction and engineering projects. Mild steel pipes are commonly used in water supply systems, construction, and manufacturing industries due to their excellent corrosion resistance, affordability, and ease of installation.

Significance of End Caps

End caps are fittings used to close the open ends of pipes, effectively sealing them and preventing the ingress of dust, moisture, and other contaminants. In the case of MS pipes, end caps play a vital role in protecting the inner integrity of the pipe from external elements and maintaining the flow of fluids within a piping system. They are also critical in ensuring safety by preventing accidental injuries caused by open pipe ends.

Types of End Caps

End caps come in various designs and materials, but when specifically talking about MS pipes, they are primarily made of mild steel or materials that can withstand significant pressure and temperature variations. The most commonly used types of end caps for MS pipes include

1. Welded End Caps These caps are welded onto the pipe ends using appropriate welding techniques. This provides a strong and robust seal that can withstand high pressure.

2. Threaded End Caps Designed to screw onto the pipe ends, threaded end caps provide a convenient way to seal the pipe while allowing for easy removal when necessary.

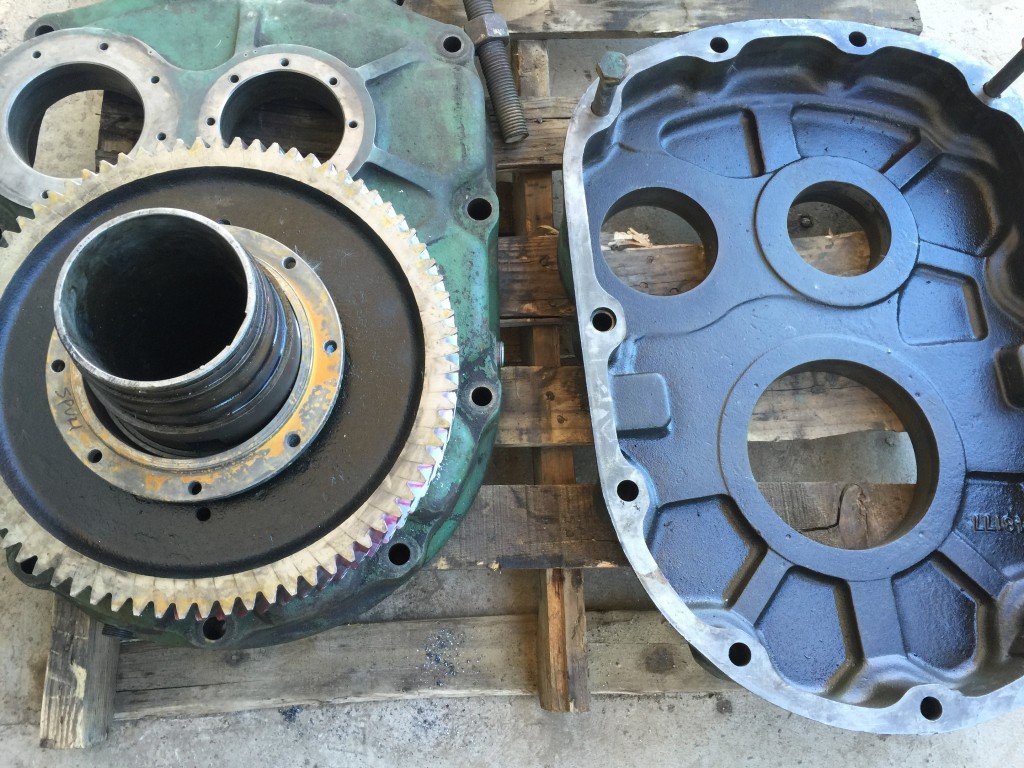

end cap for ms pipe

4. Socket Weld End Caps These caps are inserted into the pipe socket and welded in place, providing a strong connection.

Applications of End Caps for MS Pipes

End caps have a wide range of applications, including but not limited to

- Water Supply Systems End caps are used to close the ends of supply lines, ensuring that water does not leak and that contaminants do not enter the system. - Construction Projects In structural applications, end caps are used to seal pipes that are not in use, preventing debris and moisture from entering. - Manufacturing Processes In manufacturing environments, end caps are often utilized in pneumatic and hydraulic systems, where sealing is essential for maintaining pressure.

Advantages of Using End Caps

There are several advantages to using end caps with MS pipes

- Prevention of Contamination End caps protect the inner surfaces of pipes from dirt, moisture, and other contaminants. - Enhanced Safety By sealing the ends of pipes, end caps reduce the risk of accidents that could occur from exposed pipe ends. - Cost-Effectiveness Using end caps can prolong the life of piping systems by minimizing wear and tear, resulting in lower repair and maintenance costs in the long run. - Versatility Available in various designs and materials, end caps can be used across multiple applications, making them a versatile choice in the industry.

Installation of End Caps

Installing end caps on MS pipes is a straightforward process, generally involving cleaning the pipe ends, applying any necessary sealant, and then using the appropriate method (welding, screwing, or bolting) to secure the cap in place. Proper installation is crucial to ensure the seal's effectiveness and the safety of the overall piping system.

Conclusion

End caps for MS pipes are invaluable components that ensure the safety and functionality of piping systems across various industries. Understanding their significance, types, and applications is essential for those involved in construction, manufacturing, and other related fields. By choosing the right end caps and installing them correctly, businesses can enhance the durability and efficiency of their piping systems, ultimately leading to significant operational savings.