Mobile:+86-311-808-126-83

Email:info@ydcastings.com

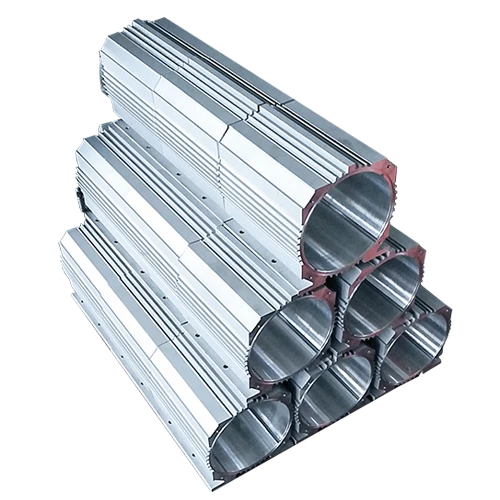

Exploring the Features and Benefits of Cap 4 for Enhanced End Performances

Understanding End Caps Enhancing Efficiency in Modern Manufacturing

In today's fast-paced manufacturing environment, efficiency and precision are paramount. One critical component that plays a significant role in ensuring these aspects is the end cap. Often overlooked, end caps are vital in a variety of applications, from plumbing and automotive to industrial machinery. This article delves into the importance of end caps, their various types, and how they enhance overall manufacturing processes.

What Are End Caps?

End caps are fittings used to close off the ends of pipes, tubes, or other structures. They serve both functional and aesthetic purposes, preventing the ingress of dust, dirt, and moisture while also providing a finished look to the product. In manufacturing, end caps also help maintain structural integrity and pressure within systems, such as hydraulic lines or pneumatic devices.

Types of End Caps

End caps come in various materials and designs, each tailored to specific applications. The most common materials include

1. Plastic Lightweight and corrosion-resistant, plastic end caps are widely used in plumbing and electrical applications. They are easy to install and cost-effective.

2. Metal Often made from steel, brass, or aluminum, metal end caps are chosen for their durability and ability to withstand high pressures and temperatures. They are frequently utilized in heavy industrial settings.

3. Rubber Used primarily in applications that require flexibility and shock absorption, rubber end caps are found in automotive and aerospace industries, providing cushioning and noise reduction.

4. Custom End Caps In many specialized applications, manufacturers may require custom-designed end caps to meet specific requirements, including unique dimensions or specialized materials.

Importance of End Caps in Manufacturing

end cap 4

1. Sealing and Protection One of the primary functions of end caps is to seal and protect the ends of tubes and pipes. This sealing capability prevents contamination and damage during shipping and storage, ensuring that products reach customers in optimal condition.

2. Pressure Maintenance In systems where pressure control is crucial—such as hydraulic machinery or high-performance engines—end caps play a critical role in maintaining pressure levels. Properly sealed end caps prevent leaks that could lead to malfunctions, downtime, and costly repairs.

3. Cost Efficiency Using the right type of end cap can reduce operational costs significantly. Effective sealing minimizes the risk of leaks and failures, which could disrupt production and lead to expensive repairs. Moreover, the right end caps can enhance the lifespan of the components they protect.

4. Aesthetic Appeal Beyond functionality, end caps provide a clean and finished look to various products. This is especially important in consumer products, where the visual aspect can influence purchasing decisions. Well-designed end caps contribute to a product's overall appeal, signaling quality to potential customers.

5. Easy Installation and Replacement Most end caps are designed for quick installation, which is essential in a manufacturing setting where time is money. Their straightforward design allows for easy replacement, minimizing downtime for machinery and equipment.

Innovations and Trends

As industries evolve, so do the designs and materials of end caps. Recent innovations include

- Smart End Caps Some manufacturers are developing end caps equipped with sensors that can monitor pressure and detect leaks in real time. This technology enhances safety and efficiency in critical applications. - Sustainable Materials In response to environmental concerns, manufacturers are increasingly turning to biodegradable and environmentally friendly materials for end caps. This trend aligns with global sustainability goals and reduces the impact of industrial waste on the environment.

Conclusion

In summary, end caps may seem like a minor component in the vast landscape of manufacturing, but their significance cannot be understated. They enhance efficiency, protect against contamination, maintain pressure, and contribute to the aesthetic value of products. As technology advances and industries seek increased efficiency, the role of end caps will undoubtedly continue to grow, driving innovations that meet the evolving needs of modern manufacturing. Investing in the right end caps is not just a matter of preference; it is a critical decision that impacts the overall performance and reliability of manufacturing operations.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025