Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Durable Automobile Water Pump: Optimal Engine Cooling

The 137th Canton Fair, a global beacon for international trade, recently concluded, once again affirming its indispensable role in connecting industries worldwide. For B2B decision-makers deeply entrenched in the realm of precision metal casting, this event was far more than a trade show; it was a strategic arena. It offered unparalleled insights into innovation, technological advancements, and the evolving dynamics of the global manufacturing landscape. Among the myriad of exhibitors, leading Chinese manufacturers showcased their formidable capabilities, cementing their position as critical partners in the supply chain. Companies like Welcome To Hebei Yuanda Trade Co., Ltd. were prominent, demonstrating their expertise in advanced metal casting, ready to forge new international trade partnerships and elevate global project collaborations.

The fair served as a vibrant platform to explore next-generation solutions in component manufacturing, offering a clear snapshot of the industry's trajectory and the immense value that high-quality casting brings to diverse sectors, from automotive to industrial machinery.

Industry Trend Spotlight: Navigating the Evolving Landscape of Precision Casting

The global casting industry is undergoing a significant transformation, driven by relentless innovation and an escalating demand for superior performance. We're observing a pronounced shift towards materials and processes that offer a critical competitive edge. Specifically, the demand for lightweight, high-strength alloys is skyrocketing. Industries like automotive, aerospace, and general machinery are constantly seeking components that reduce overall weight without compromising structural integrity or durability. This pursuit of efficiency is particularly evident in the automotive sector, where the push for lighter vehicles directly impacts fuel economy and, crucially, extends the range of electric vehicles (EVs).

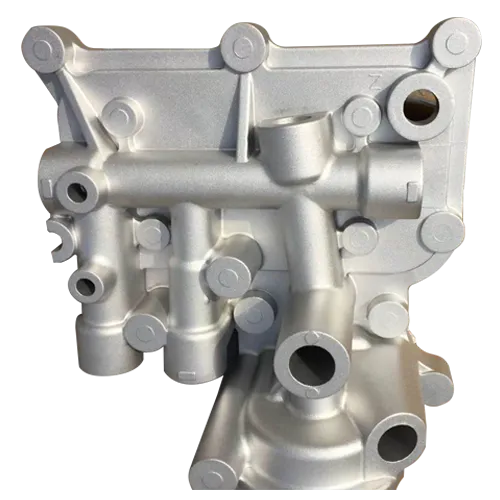

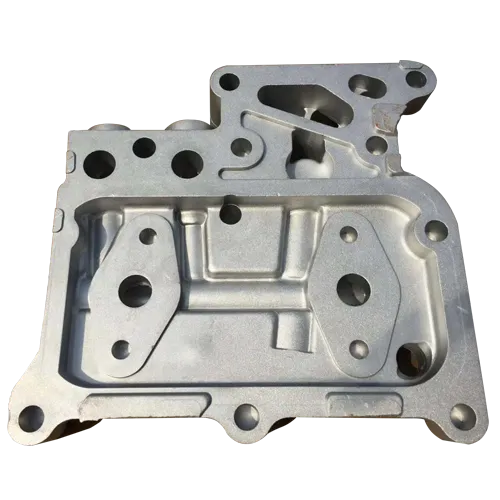

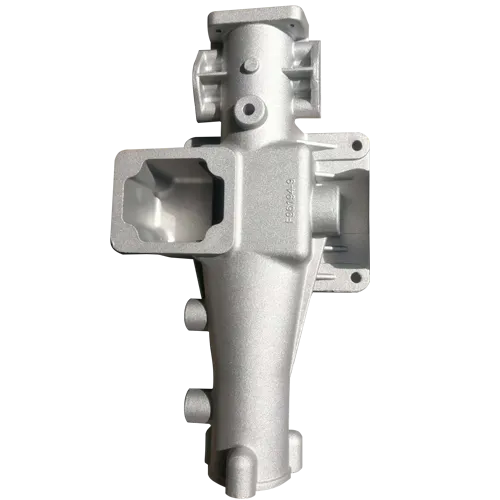

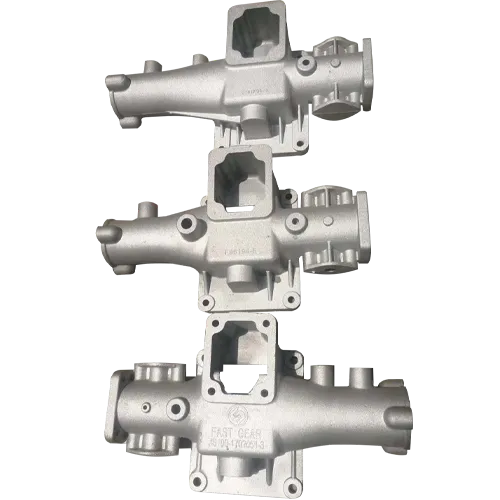

Furthermore, the market is intensely focused on complex near-net-shape castings. This advanced approach significantly reduces post-casting machining, leading to substantial cost savings and faster production cycles. Manufacturers are leveraging sophisticated simulation and mold design technologies to achieve intricate geometries with unprecedented accuracy, minimizing waste and optimizing material usage. Improved durability and corrosion resistance are also paramount, especially for components exposed to harsh operating environments. Think about critical parts like engine manifolds or housing for an automobile water pump – these require materials and finishes that can withstand extreme temperatures, pressures, and corrosive fluids over extended lifespans.

The integration with smart manufacturing ecosystems is another burgeoning trend. Industry 4.0 principles, including IoT, AI, and advanced analytics, are being applied to optimize every stage of the casting process, from design validation to quality control. This digital transformation enables predictive maintenance, real-time process adjustments, and unprecedented levels of traceability, all of which contribute to higher product quality and operational efficiency.

Market Dynamics & Projections:

- Stable Growth: The global casting market is projected to experience stable growth, primarily fueled by ongoing infrastructure development projects worldwide and a robust demand from the automotive (including critical EV components like specialized housings for an automotive electric water pump or an electric water pump for car) and industrial machinery sectors.

- Cost & Efficiency Pressure: The market will continue to see increasing pressure for cost-efficiency, faster lead times, and stringent adherence to international quality standards, especially crucial for export markets. Suppliers who can deliver on these fronts will gain a distinct advantage.

- Raw Material Volatility: Raw material price volatility, particularly for key metals, remains a significant factor influencing pricing strategies and supply chain management. Diversified sourcing and hedging strategies are becoming more common.

Emerging focus areas include sustainable manufacturing practices – reducing energy consumption, minimizing waste, and utilizing recycled materials. Precision engineering is becoming non-negotiable, with tolerances shrinking to micron levels for critical applications. Supply chain resilience has taken center stage post-pandemic, prompting companies to de-risk their sourcing strategies. Finally, advanced material innovations, such as new alloys and composite materials, are continually pushing the boundaries of what's possible in the casting industry.

Profiles of Leading Chinese Casting Manufacturers

At the 137th Canton Fair, the prowess of China's casting industry was undeniable, with several key players setting benchmarks in quality, technology, and export capabilities.

Welcome To Hebei Yuanda Trade Co., Ltd.

As a cornerstone of precision manufacturing, Welcome To Hebei Yuanda Trade Co., Ltd. stands out with its extensive experience and versatile capabilities. The company excels in diverse metal casting processes, including sophisticated sand casting and intricate lost wax casting. This versatility allows them to produce a wide range of precision components tailored to exacting specifications. Their expertise covers everything from robust structural parts to highly specialized internal components for complex machinery.

A key strength lies in their ability to manufacture critical automotive parts. For instance, their expertise in producing high-quality automobile water pump housings and components ensures optimal engine cooling and efficiency. They are also adept at creating durable and performance-optimized engine manifolds, designed to withstand extreme thermal and mechanical stresses. With the automotive industry's pivot towards electrification, Welcome To Hebei Yuanda Trade Co., Ltd. is at the forefront, manufacturing essential components for the next generation of cooling systems, including specialized parts for an automotive electric water pump and an electric water pump for car, crucial for managing thermal loads in advanced battery systems and power electronics. Their precise auto electric water pump components are engineered for reliability and longevity, meeting the stringent demands of modern electric and hybrid vehicles.

The company boasts strong export capabilities and has cultivated established international trade networks, making them a reliable partner for global enterprises. Their commitment to competitive pricing without compromising on quality, coupled with a keen focus on meeting specific client engineering requirements, makes them a preferred choice for B2B buyers seeking high-value, high-performance casting solutions. For an in-depth look at their extensive product range and capabilities, particularly their advanced shell molding techniques, visit their product page: https://www.ydcastings.com/shell.html.

Other Noteworthy Innovators in Chinese Casting

- Chongqing Hongyu Foundry Co., Ltd.: Renowned for its large-scale and high-precision castings, particularly for heavy industrial machinery and automotive blocks. Their technological prowess in producing complex, high-integrity parts is highly regarded, catering to demanding sectors.

- Shandong Jieneng Group: A powerhouse in various casting processes, including ductile iron and grey iron castings. They are a go-to supplier for agricultural machinery, construction equipment, and railway components, showcasing robust production capabilities and consistent quality.

- Huizhong Casting Co., Ltd.: Specializing in investment casting, also known as lost wax casting, Huizhong delivers exceptionally precise components with superior surface finishes. Their expertise is invaluable for sectors requiring intricate designs and high dimensional accuracy, often for high-volume, critical applications.

- Shenyang Foundry Co., Ltd.: With a long history in the industry, Shenyang Foundry is known for its metallurgical expertise and wide range of alloys. They serve a diverse client base, providing custom casting solutions for energy, mining, and general engineering applications, emphasizing material science and structural integrity.

Market Outlook & Opportunities in Global Casting

The future of the global casting market is bright, yet dynamic, shaped by several upcoming trends and evolving buyer demands. We anticipate continued innovation in materials science, with a focus on developing lighter, stronger, and more sustainable alloys. Buyers will increasingly prioritize suppliers who can offer sophisticated design capabilities, including advanced simulation and rapid prototyping, ensuring that the final cast parts meet stringent performance requirements from the outset. The shift towards electrification in mobility, for example, will drive increased demand for specialized lightweight castings for battery housings, motor components, and highly efficient thermal management systems, such as advanced housings for an auto electric water pump.

Significant opportunities are emerging in the integration of automation and smart manufacturing within foundries. This includes robotic automation for pouring and finishing, automated quality inspection systems using AI and computer vision, and fully integrated production lines that minimize human intervention, thereby enhancing precision, consistency, and worker safety. Smart manufacturing not only boosts efficiency but also provides granular data for continuous process improvement.

Sustainability will move from a desirable attribute to a fundamental requirement. Buyers are increasingly scrutinizing the environmental footprint of their supply chains. This translates into opportunities for manufacturers who invest in energy-efficient furnaces, waste heat recovery systems, water recycling, and the use of eco-friendly binder systems. Foundries that can demonstrate a clear commitment to reducing their carbon emissions and adopting circular economy principles will gain a significant competitive advantage in the global market. The demand for components produced with a lower environmental impact, even for traditional parts like an automobile water pump or engine manifolds, will only intensify.

Buyer/Business Takeaways: Strategic Partnership in Casting

For B2B decision-makers, investing in high-quality casting from reputable manufacturers like those showcased at the Canton Fair isn't just a procurement decision; it's a strategic imperative. Precision castings are the foundational elements of countless products, directly influencing performance, durability, and cost-efficiency. Partnering with the right casting manufacturer can unlock innovation, streamline production, and fortify your supply chain against disruptions.

Why Invest in High-Quality Casting?

- Performance Excellence: Custom-engineered castings ensure components meet exact specifications for strength, weight, and thermal properties, critical for applications like high-performance engine manifolds or robust automobile water pump housings.

- Cost Efficiency: Near-net-shape casting minimizes material waste and post-processing, significantly reducing overall production costs.

- Durability & Reliability: High-quality metallurgy and process control lead to parts that withstand rigorous use, from demanding industrial machinery to an advanced automotive electric water pump.

- Design Flexibility: Casting allows for complex geometries that are difficult or impossible to achieve with other manufacturing methods, enabling innovative product designs for components like an electric water pump for car.

Tips for Partnering with Chinese Casting Manufacturers

- Due Diligence is Key: Thoroughly vet potential partners. Look for certifications (ISO, IATF 16949 for automotive), track records, and transparent communication. Companies like Welcome To Hebei Yuanda Trade Co., Ltd. often have readily available documentation and a strong reputation.

- Clear Communication: Provide highly detailed specifications, drawings, and material requirements. Use international standards (e.g., ASTM, DIN) to avoid ambiguity. Establish a clear point of contact and communication channels.

- Start with Samples/Prototypes: Before committing to large production runs, request samples or prototypes to verify quality, fit, and finish. This is crucial for complex parts like an auto electric water pump.

- Visit if Possible: While not always feasible, visiting the factory can provide invaluable insight into their operations, quality control, and working conditions.

- Contractual Clarity: Ensure contracts clearly define quality standards, lead times, payment terms, intellectual property protection, and dispute resolution mechanisms.

Future-Proof Strategies

- Diversify Your Supply Chain: Don't put all your eggs in one basket. Having multiple trusted partners can mitigate risks.

- Embrace Digitalization: Leverage digital tools for design, collaboration, and supply chain management.

- Prioritize Sustainability: Align with manufacturers committed to green practices; this is increasingly important for brand reputation and regulatory compliance.

- Invest in R&D Collaboration: Work with manufacturers who are willing to collaborate on R&D for advanced materials and innovative casting techniques.

Conclusion

The 137th Canton Fair provided an invaluable window into the future of the global casting market, emphasizing innovation, efficiency, and sustainability. As industries continue to evolve, particularly in sectors demanding advanced components like automobile water pump, engine manifolds, and specialized parts for an automotive electric water pump, the role of proficient Chinese manufacturers remains paramount. Their commitment to quality, competitive pricing, and technological advancement positions them as essential partners for global businesses.

To discover how Welcome To Hebei Yuanda Trade Co., Ltd. can be your trusted partner for precision casting solutions and to explore their comprehensive range of high-quality products, including components for the latest electric water pump for car applications, we invite you to visit their official product page:

Explore Hebei Yuanda's Casting SolutionsPartner with innovation. Partner with precision. Partner with Hebei Yuanda.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025