Mobile:+86-311-808-126-83

Email:info@ydcastings.com

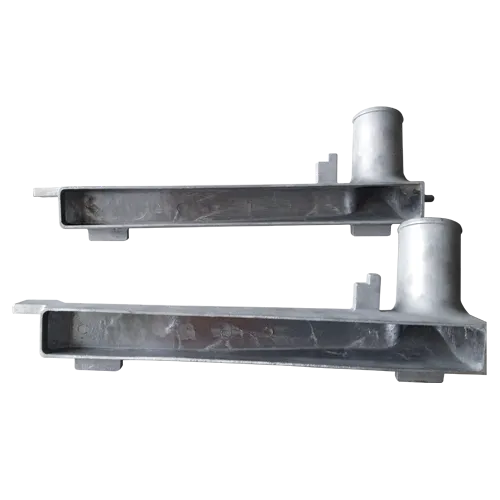

dual impeller

The Dual Impeller A Revolutionary Innovation in Fluid Dynamics

In the realm of fluid dynamics, the innovation of the dual impeller system has emerged as a significant advancement, particularly in the fields of engineering and industrial applications. The dual impeller design, which features two impellers working in tandem, offers numerous benefits that enhance performance, efficiency, and adaptability in various systems. This article delves into the fundamentals of dual impeller technology, its applications, advantages, and future prospects.

Understanding the Dual Impeller System

At its core, an impeller is a rotating component of a machine that transfers energy from a motor to fluid. Traditional single impeller systems operate effectively; however, they can face limitations in terms of flow rates, pressure generation, and overall efficiency. The dual impeller system addresses these challenges by incorporating two impellers that work together to move fluid more efficiently. These impellers can be arranged in series or in parallel configuration, depending on the specific requirements of the application.

In a series configuration, the first impeller increases the fluid's pressure before directing it to the second impeller for further pressure enhancement. This setup is particularly beneficial for applications requiring high pressure or when pumping fluids through long distances. Conversely, in a parallel configuration, both impellers operate simultaneously to increase the flow rate, making this arrangement ideal for systems that need to handle larger volumes of fluid quickly.

Applications of Dual Impeller Technology

The dual impeller system finds its applications across a broad spectrum of industries. In the water treatment sector, for instance, dual impellers are used in centrifugal pumps designed to efficiently move water through filtration systems. This ensures optimal fluid transport while minimizing energy consumption.

In the aerospace industry, dual impeller systems are also gaining traction, particularly in jet engines and fuel pumps. The ability to control fuel flow accurately and efficiently is critical for maximizing performance and safety in aviation applications.

Moreover, dual impellers are instrumental in chemical processing and petrochemical industries, where they are used in reactors and mixers to ensure even distribution and mixing of various chemical constituents. This not only enhances the reaction rates but also leads to efficient heat transfer and improved product quality.

dual impeller

Advantages of Dual Impeller Systems

One of the primary advantages of a dual impeller design is its ability to enhance operational efficiency. With two impellers working in harmony, the system can achieve higher flow rates and pressures without significantly increasing energy consumption, leading to reduced operating costs and energy expenses.

Additionally, dual impeller systems provide greater reliability and durability. By distributing the workload between two impellers, wear and tear are minimized, which extends the lifespan of the equipment. This reliability makes dual impeller systems particularly appealing for critical applications where failure is not an option.

Furthermore, these systems offer improved adaptability. By allowing for flexible configuration options, dual impellers can be tailored to meet specific operational needs, thus making them a versatile solution in various industrial contexts.

Future Prospects

As industries continue to evolve, the future of dual impeller technology looks promising. Ongoing research and development in fluid dynamics, materials science, and engineering are expected to yield new designs that further enhance the performance and efficiency of dual impeller systems. Advancements in computational fluid dynamics (CFD) will also likely facilitate more precise modeling, leading to better designs and optimized operations.

The push for sustainability and energy efficiency will further drive the adoption of dual impeller technology, as organizations seek to reduce their carbon footprint and operational costs. With the growing emphasis on sustainability, innovations in dual impeller systems could play a pivotal role in developing environmentally friendly and efficient industrial processes.

Conclusion

The dual impeller system represents a significant advance in fluid dynamics technology, providing a myriad of advantages in various applications across multiple industries. As development continues and industries strive for greater efficiency, the dual impeller is poised to become a cornerstone technology that addresses modern challenges and paves the way for a more sustainable and capable industrial future. As we harness the capabilities of dual impellers, we can anticipate a transformation in how we manage fluid dynamics, ensuring enhanced performance and efficiency for years to come.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025