Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Different Varieties of Blower Impellers and Their Applications in Various Industries

Types of Blower Impellers An Overview

Blowers are vital components in various industrial applications, responsible for moving air or gas within a system. One of the most crucial elements of any blower is its impeller. The impeller is the rotating component that imparts kinetic energy to the air or gas, creating flow and pressure. The design and type of impeller used can significantly affect the efficiency, performance, and suitability of a blower for a specific application. This article will explore the different types of blower impellers, their characteristics, and their practical applications.

1. Centrifugal Impellers

Centrifugal impellers are among the most commonly used types in blowers. They operate on the principle of centrifugal force, which drives the air or gas outward from the center of the impeller to its periphery. This design allows for high flow rates and increases the pressure of the moving air. Centrifugal impellers can further be categorized into various subtypes

- Open Impellers Featuring no back shroud, open impellers allow for easier passage of particulates and are typically used for applications involving dirty or abrasive gases. Their simple design facilitates easy cleaning and maintenance.

- Closed Impellers Enclosed by a front and back shroud, closed impellers are more efficient than open ones and are designed for applications requiring higher pressure. They are typically used in clean air applications, providing better energy transfer.

- Semi-closed Impellers These impellers combine features from the first two types, featuring a back shroud but an open front. They are versatile and can handle a variety of applications while providing a good balance between efficiency and robustness.

Axial impellers, as the name suggests, move air along the axis of the impeller. Unlike centrifugal impellers, axial impellers rely on their blades to create lift, similar to aircraft propellers. These designs are ideal for applications requiring high flow rates but lower pressure, making them suitable for ventilating large areas or cooling systems.

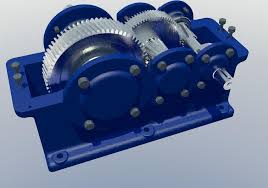

types of blower impeller

Axial impellers are often favored in scenarios where space is at a premium, as they typically have a more compact design compared to centrifugal impellers. They come in various shapes, including

- Propeller Blades These usually have a larger diameter and operate at lower speeds, suitable for high-volume applications.

- Dihedral Blades These blades are designed with a specific angle to improve efficiency and prevent stall conditions.

3. Mixed Flow Impellers

Mixed flow impellers combine the principles of both centrifugal and axial designs. They can move air both radially and axially, providing a compromise between pressure and flow rate. Mixed flow impellers are often utilized in applications where space is limited and moderate pressure is required. They are versatile and capable of handling various gas densities and volumes.

Applications of Blower Impellers

The choice of blower impeller largely depends on the application. In pneumatic conveying systems, for example, centrifugal impellers are often preferred for their ability to handle bulk materials efficiently. In commercial HVAC systems, axial impellers are commonly used for ventilation purposes due to their high airflow capacity.

In summary, the selection of the appropriate blower impeller is crucial for achieving optimal performance in various applications. Understanding the types of impellers—centrifugal, axial, and mixed flow—along with their specific characteristics and uses allows engineers and manufacturers to choose the right design for their needs. Whether dealing with high-pressure systems or high-flow ventilation, the right impeller can make all the difference in operational efficiency and reliability.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025