Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Emerging Trends and Key Players in the Die Casting Industry Today

The World of Die-Cast Manufacturers An Overview

Die casting is a manufacturing process that has gained immense popularity due to its efficiency in producing high-quality metal parts. This technique involves forcing molten metal into a mold cavity under high pressure, enabling manufacturers to create complex shapes with exceptional precision. Die-cast manufacturers play a crucial role in various industries, including automotive, aerospace, electronics, and consumer products. This article explores the significance, processes, and trends within the die-casting industry.

The Significance of Die Casting

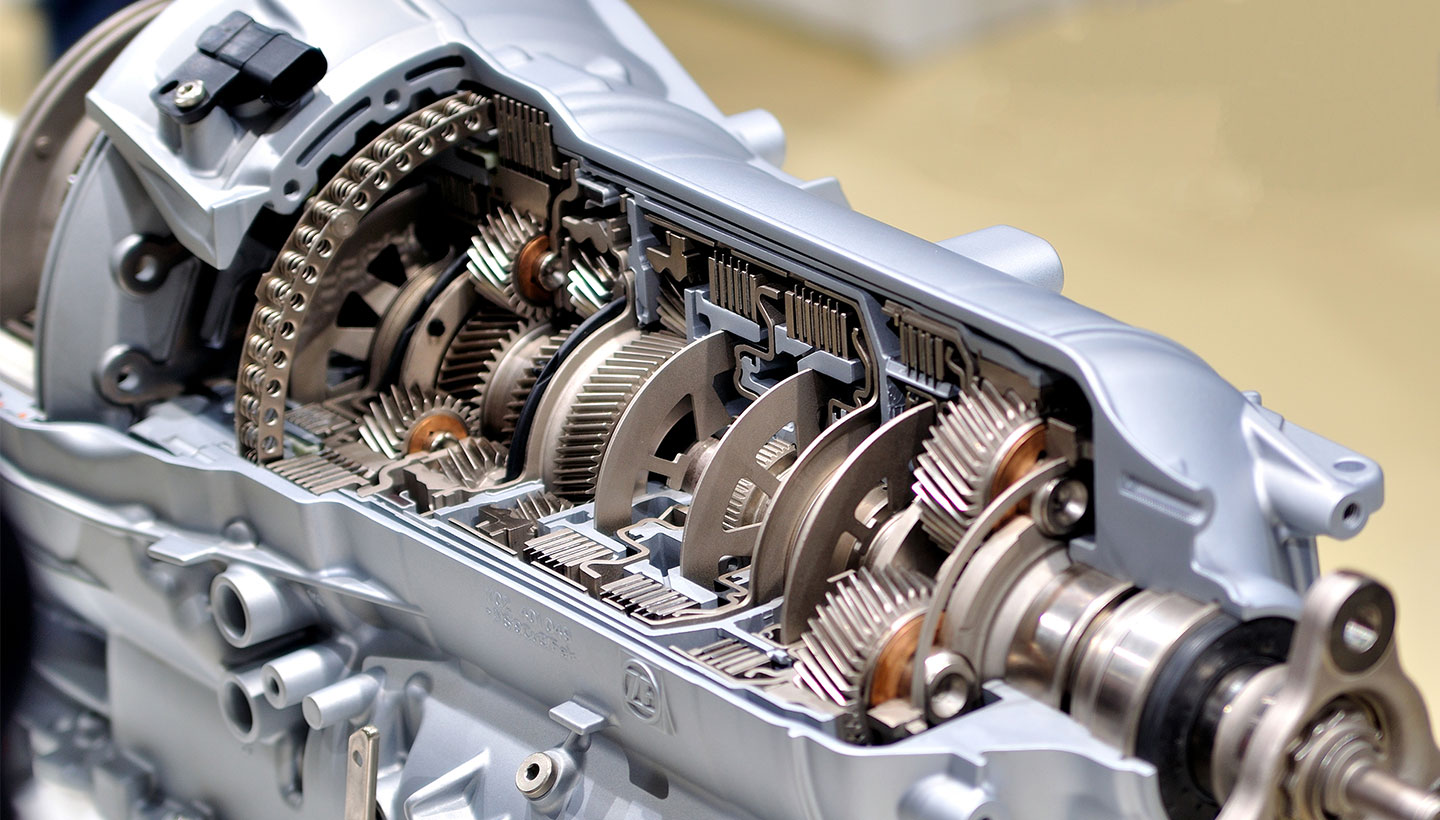

Die casting is essential for modern manufacturing due to its ability to produce parts that are not only dimensionally accurate but also possess a smooth finish. This process is favored for its speed, as it allows for the mass production of components, significantly reducing lead times. The durability and lightweight nature of die-cast parts make them ideal for industries such as automotive, where fuel efficiency is paramount. In fact, many car manufacturers rely on die-cast components for engine blocks, transmission cases, and other critical components to enhance performance and reduce weight.

The Die-Casting Process

1. Mold Creation The first step in die casting is the development of the mold, which is usually made from steel. These molds can be quite expensive due to their complexity and the precision required in their construction. However, they are built to withstand thousands of cycles, making them a worthwhile investment for high-volume production.

2. Metal Melting The metal chosen for die casting, commonly aluminum, zinc, or magnesium, is melted in a furnace. The selection of metal depends on the application; for example, aluminum is lightweight and resistant to corrosion, making it a popular choice in the automotive industry.

3. Injection Once the metal is melted, it is injected into the mold under high pressure, filling the cavity completely. The pressure ensures that even the most intricate designs are captured accurately.

die cast manufacturers

4. Cooling After the mold is filled, it is cooled, allowing the metal to solidify. The cooling time depends on the thickness of the casting and the complexity of the mold.

5. Ejection Once solidified, the mold is opened, and the die-cast part is ejected. The process may involve trimming or machining to achieve the desired finish and tolerances.

Trends in Die Casting

The die-casting industry continues to evolve, influenced by advancements in technology and changing market demands. One notable trend is the increasing use of automation and robotics in the manufacturing process. Automated systems enhance precision, reduce labor costs, and improve overall efficiency.

Additionally, there is a growing focus on sustainability. As industries strive for greener practices, die-cast manufacturers are exploring environmentally friendly materials and processes. This includes using recyclable metals, optimizing energy consumption during production, and minimizing waste generation.

Another significant trend is the integration of advanced manufacturing techniques, such as 3D printing, into the die-casting workflow. 3D printing can be used to develop prototypes or even complex mold configurations, thus reducing the time required for product development.

Conclusion

Die-cast manufacturers are at the heart of modern manufacturing, providing vital components for various industries. The combination of precision, efficiency, and the ability to produce complex designs makes die casting a preferred choice across many sectors. As the industry adapts to new technologies and sustainability initiatives, the future of die casting looks promising. By continuing to innovate and optimize processes, die-cast manufacturers will remain pivotal in the ever-evolving landscape of manufacturing.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025