Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Jun . 28, 2024 11:40

Back to list

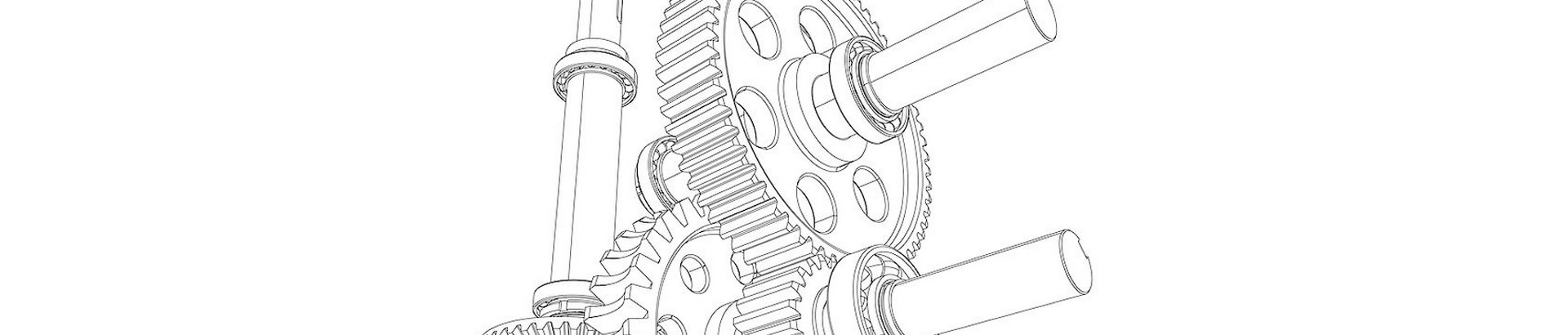

Designing and Fabrication of Bevel Gear Enclosure A Comprehensive Approach

Understanding the Significance of Bevel Gear Housing in Mechanical Engineering

In the intricate world of mechanical engineering, bevel gear housing holds a pivotal position due to its functionality and durability. A bevel gear housing, also known as a bevel gear case or carrier, is a critical component that houses the bevel gears, playing an essential role in the transmission of power and torque between intersecting shafts at a 90-degree angle.

Bevel gears, with their conical shape, are designed to facilitate the change in direction of the rotational force. They are commonly used in applications where two shafts meet at an angle, such as in automotive differentials, machine tools, and various industrial machinery. The housing that protects and supports these gears is equally significant, as it ensures the gears operate smoothly, efficiently, and safely.

The primary function of the bevel gear housing is to provide a sturdy framework for the gears, maintaining their alignment and preventing any unwanted movement. It is typically made from robust materials like cast iron or steel, offering exceptional strength and resistance against wear and tear. This robust construction not only safeguards the gears from external damage but also minimizes vibrations, enhancing the overall performance and longevity of the system.

Moreover, the housing acts as a barrier, containing lubricants necessary for the smooth operation of the gears. It prevents lubricant leakage, ensuring continuous lubrication and reducing friction, which could otherwise lead to premature gear wear It prevents lubricant leakage, ensuring continuous lubrication and reducing friction, which could otherwise lead to premature gear wear It prevents lubricant leakage, ensuring continuous lubrication and reducing friction, which could otherwise lead to premature gear wear It prevents lubricant leakage, ensuring continuous lubrication and reducing friction, which could otherwise lead to premature gear wear

It prevents lubricant leakage, ensuring continuous lubrication and reducing friction, which could otherwise lead to premature gear wear It prevents lubricant leakage, ensuring continuous lubrication and reducing friction, which could otherwise lead to premature gear wear bevel gear housing. The design of the housing often includes channels or passages to guide the lubricant to the critical areas, further improving the efficiency and lifespan of the gears.

Bevel gear housings can be customized to suit specific application requirements. They may incorporate features like cooling fins to dissipate heat generated during operation, or additional mounting points for easy integration into complex systems. Precision machining and engineering ensure a precise fit between the gears and the housing, minimizing clearance and increasing the accuracy of the gear mesh.

In conclusion, the bevel gear housing is more than just a protective casing; it is a vital element that contributes significantly to the efficient functioning and reliability of mechanical systems involving bevel gears. Its importance lies in its ability to maintain gear stability, ensure proper lubrication, and withstand the harsh conditions prevalent in various industries. As technology advances, so does the design and manufacturing of bevel gear housings, continuously striving for improved performance, durability, and adaptability in an ever-evolving mechanical landscape.

bevel gear housing. The design of the housing often includes channels or passages to guide the lubricant to the critical areas, further improving the efficiency and lifespan of the gears.

Bevel gear housings can be customized to suit specific application requirements. They may incorporate features like cooling fins to dissipate heat generated during operation, or additional mounting points for easy integration into complex systems. Precision machining and engineering ensure a precise fit between the gears and the housing, minimizing clearance and increasing the accuracy of the gear mesh.

In conclusion, the bevel gear housing is more than just a protective casing; it is a vital element that contributes significantly to the efficient functioning and reliability of mechanical systems involving bevel gears. Its importance lies in its ability to maintain gear stability, ensure proper lubrication, and withstand the harsh conditions prevalent in various industries. As technology advances, so does the design and manufacturing of bevel gear housings, continuously striving for improved performance, durability, and adaptability in an ever-evolving mechanical landscape.

It prevents lubricant leakage, ensuring continuous lubrication and reducing friction, which could otherwise lead to premature gear wear It prevents lubricant leakage, ensuring continuous lubrication and reducing friction, which could otherwise lead to premature gear wear

It prevents lubricant leakage, ensuring continuous lubrication and reducing friction, which could otherwise lead to premature gear wear It prevents lubricant leakage, ensuring continuous lubrication and reducing friction, which could otherwise lead to premature gear wear bevel gear housing. The design of the housing often includes channels or passages to guide the lubricant to the critical areas, further improving the efficiency and lifespan of the gears.

Bevel gear housings can be customized to suit specific application requirements. They may incorporate features like cooling fins to dissipate heat generated during operation, or additional mounting points for easy integration into complex systems. Precision machining and engineering ensure a precise fit between the gears and the housing, minimizing clearance and increasing the accuracy of the gear mesh.

In conclusion, the bevel gear housing is more than just a protective casing; it is a vital element that contributes significantly to the efficient functioning and reliability of mechanical systems involving bevel gears. Its importance lies in its ability to maintain gear stability, ensure proper lubrication, and withstand the harsh conditions prevalent in various industries. As technology advances, so does the design and manufacturing of bevel gear housings, continuously striving for improved performance, durability, and adaptability in an ever-evolving mechanical landscape.

bevel gear housing. The design of the housing often includes channels or passages to guide the lubricant to the critical areas, further improving the efficiency and lifespan of the gears.

Bevel gear housings can be customized to suit specific application requirements. They may incorporate features like cooling fins to dissipate heat generated during operation, or additional mounting points for easy integration into complex systems. Precision machining and engineering ensure a precise fit between the gears and the housing, minimizing clearance and increasing the accuracy of the gear mesh.

In conclusion, the bevel gear housing is more than just a protective casing; it is a vital element that contributes significantly to the efficient functioning and reliability of mechanical systems involving bevel gears. Its importance lies in its ability to maintain gear stability, ensure proper lubrication, and withstand the harsh conditions prevalent in various industries. As technology advances, so does the design and manufacturing of bevel gear housings, continuously striving for improved performance, durability, and adaptability in an ever-evolving mechanical landscape. Latest news

-

Why Is Choosing the Right Motor Housing Critical for Engine Performance?NewsJul.18,2025

-

Which Impeller Types Best Optimize Your Pump’s Efficiency?NewsJul.18,2025

-

Optimize Maintenance Efficiency with Durable Oil Catch SolutionsNewsJul.18,2025

-

Maximize Pump Performance with Precision-Engineered ComponentsNewsJul.18,2025

-

Elevate Industrial Flow Systems with Precision-Engineered ComponentsNewsJul.18,2025

-

Boost Durability and Functionality with Precision Power CastingsNewsJul.18,2025

Related PRODUCTS