Mobile:+86-311-808-126-83

Email:info@ydcastings.com

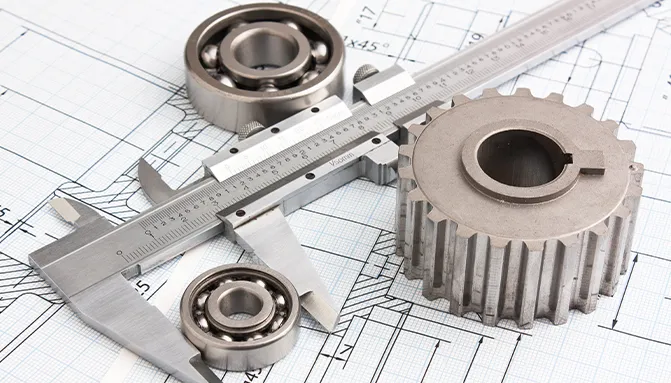

compressor housing turbo

Understanding the Role of Compressor Housing in Turbochargers

Turbocharging technology has revolutionized the automotive and aerospace industries by enhancing the performance and efficiency of internal combustion engines. Among the key components of a turbocharger, the compressor housing plays a pivotal role in its functionality. This article delves into the significance of the compressor housing, its design features, and the advancements that have emerged in this crucial turbocharger component.

What is a Compressor Housing?

The compressor housing is a critical part of the turbocharger that encloses the compressor wheel. It is typically made from durable materials such as aluminum or cast iron, designed to withstand high temperatures and pressures generated during operation. The primary function of the compressor housing is to direct the flow of air from the ambient environment to the engine intake, effectively enhancing the engine's air supply and, subsequently, its power output.

Design Features of Compressor Housing

The design of the compressor housing is instrumental in determining the efficiency and performance of the turbocharger

. Several design features contribute to its effectiveness1. Inlet Design The inlet of the compressor housing is designed to efficiently capture and channel atmospheric air into the compressor wheel. Its shape and size can significantly influence the airflow dynamics, affecting overall performance. A well-designed inlet minimizes turbulence and resistance, ensuring that air enters the compressor wheel smoothly.

2. Volute Geometry The volute is the spiral-shaped section of the compressor housing that guides air flow. The specific geometry of the volute is crucial for optimizing the air's velocity and pressure as it enters the compressor wheel. Advanced computational fluid dynamics (CFD) techniques are often employed in the design phase to optimize volute contours, leading to improved efficiency and performance.

compressor housing turbo

3. Outlet Configuration The outlet of the compressor housing must be designed to facilitate smooth airflow into the engine. A properly sized and shaped outlet prevents back pressure, which can adversely affect turbocharger performance. Designers often analyze the relationship between compressor outlet size and engine intake requirements to achieve a balanced setup.

Importance of Material Selection

The materials used in manufacturing compressor housings are vital for their longevity and effectiveness. The harsh operating conditions—high temperatures and pressure fluctuations—demand that these components be robust yet lightweight. Aluminum alloys are commonly chosen for their favorable strength-to-weight ratio, while materials like cast iron may be employed for heavier-duty applications or in high-performance settings. Recent innovations in material science have led to the development of composite materials that exhibit excellent thermal resistance and reduced weight, further enhancing turbocharger performance.

Advancements in Compressor Housing Technology

As automotive technology advances, so do the components that make up the turbocharger. Recent innovations in compressor housing design have focused on achieving higher efficiency and lower emissions. One notable trend is the integration of variable geometries within the compressor housing, allowing for dynamic adjustment of airflow based on engine needs. This adaptability enhances performance across different RPM ranges, leading to a more responsive driving experience.

Furthermore, the introduction of additive manufacturing (3D printing) has transformed how compressor housings are produced. This technology allows for complex geometries that were previously difficult to achieve using conventional methods. By leveraging 3D printing, manufacturers can create lighter, more efficient compressor housings with intricate internal features that optimize airflow.

Conclusion

The compressor housing is far more than just a protective cover for the compressor wheel; it is a critical component that directly influences turbocharger performance and efficiency. Through innovative designs, advanced material choices, and cutting-edge manufacturing techniques, the evolution of compressor housings has mirrored the rapid advancements in turbocharging technology. As engines become more powerful and efficient, the role of the compressor housing will undoubtedly grow in significance, cementing its position as a key player in the ever-evolving landscape of automotive and aerospace engineering. Continued research and development in this area promise to unlock even greater levels of performance and efficiency, driving the future of turbocharged engines.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025