Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Understanding the Benefits of Closed Type Impellers in Pump Design and Efficiency

Understanding Closed Type Impellers Features, Applications, and Benefits

In the realm of fluid dynamics and pump technology, the design and function of impellers play a crucial role in ensuring efficient fluid movement. One prominent type of impeller is the closed type impeller, renowned for its effectiveness in various applications. This article aims to delve into the characteristics, advantages, and applicable fields of closed type impellers, providing a comprehensive overview for those interested in pump design and operation.

What is a Closed Type Impeller?

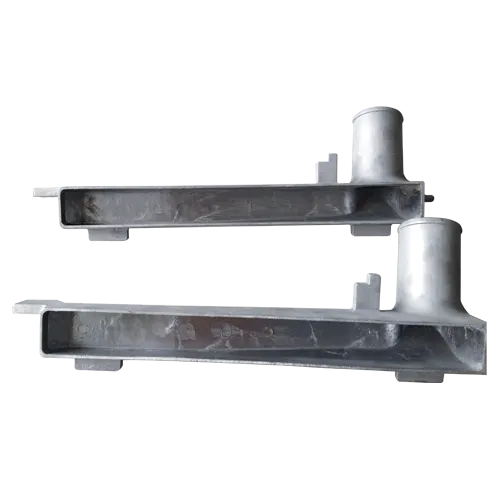

A closed type impeller, also known as a enclosed impeller, consists of two shrouds or covers that encapsulate the blades. Unlike open impellers, which lack a front cover and allow fluid to flow freely around the blades, closed impellers utilize a sealed design to enhance performance. The enclosed structure not only supports the blades but also promotes a more controlled flow of the fluid, resulting in improved efficiency.

The closed type impeller can be constructed from various materials, including cast iron, stainless steel, and composite materials, making it suitable for diverse applications and environments. Its design is particularly favored in systems dealing with high pressures, as the closed configuration helps containing the pressures within the impeller better than the open design.

Advantages of Closed Type Impellers

1. Increased Efficiency One of the primary benefits of closed type impellers is their efficiency. The design minimizes turbulence and recirculation, allowing for a more direct and streamlined pathway for fluid flow. This increased efficiency translates into reduced energy consumption, making closed type impellers an environmentally friendly choice.

2. Higher Pressure Handling Closed type impellers are capable of handling higher pressures compared to their open counterparts. This quality makes them particularly suitable for applications in industries such as oil and gas, chemical processing, and water treatment, where high-pressure fluid movement is essential.

3. Reduced Risk of Cavitation The risk of cavitation— the formation of vapor bubbles in a liquid— is significantly reduced in closed impellers. Cavitation can lead to severe damage and decreased performance in pumping systems. The enclosed design helps maintain stable pressure within the impeller, minimizing the chances of cavitation occurring.

4. Versatility Across Applications Closed type impellers can be used in a wide range of applications, including centrifugal pumps, submersible pumps, and many industrial processes. Their ability to efficiently move various types of fluids, from water to viscous substances, makes them invaluable across different sectors.

closed type impeller

5. Improved Lifespan and Maintenance Due to their robust design, closed type impellers generally experience less wear and tear, leading to longer service lives and reduced maintenance costs. The enclosed nature protects the impeller blades from external elements, further enhancing durability.

Applications of Closed Type Impellers

Closed type impellers find extensive use in numerous industries due to their efficiency and robustness. Key applications include

- Water Treatment Plants In water supply and wastewater treatment, closed impellers efficiently transport large volumes of water while withstanding varying pressures and flow conditions.

- Chemical Processing The chemical industry often requires pumps capable of handling corrosive or volatile materials. Closed type impellers provide the necessary durability and reliability.

- HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, closed impellers are employed to circulate fluids effectively, contributing to energy-efficient heat exchange.

- Agricultural Irrigation Modern irrigation systems rely on closed type impellers to transport water efficiently over large distances, ensuring crops receive adequate hydration with minimal energy loss.

Conclusion

Closed type impellers play a pivotal role in enhancing the performance and reliability of pumping systems across various industries. Their design not only boosts efficiency but also addresses critical challenges such as pressure handling and cavitation. Understanding the advantages and diverse applications of closed type impellers allows engineers and industry professionals to make informed decisions when selecting impellers for specific fluid handling needs. As technology continues to evolve, the importance of efficient and reliable impeller designs like the closed type will only grow, shaping the future of fluid dynamics and pumping systems.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025