Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Comparison of CF8 and CF8M Materials in Industrial Applications

Understanding CF8 and CF8M The Basics of Stainless Steel Grades

When it comes to material selection in industries ranging from chemical processing to food production, the choice of stainless steel is vital. Among the myriad of stainless steel grades available, CF8 and CF8M are two commonly utilized types. Understanding these materials is crucial for engineers, designers, and manufacturers eager to optimize their applications and ensure durability and resistance to corrosion.

What are CF8 and CF8M?

CF8 and CF8M are specifications derived from the ASTM A351 standard for cast stainless steels. They are primarily used in the manufacturing of pipes, fittings, and valves, with particular emphasis on applications involved in corrosive environments. Both alloys contain a high percentage of chromium, which provides excellent resistance to oxidation and corrosion, making them highly desirable in many industrial applications.

The primary differences between CF8 and CF8M lie in their chemical composition, particularly concerning their nickel and molybdenum content. CF8 is typically a cast form of the 304 stainless steel composition, comprising approximately 18% chromium and 8% nickel. This alloy exhibits good mechanical properties and longevity in a variety of environments.

On the other hand, CF8M is a modification of CF8 with enhanced properties attributable to the addition of molybdenum—usually around 2%-3%. The presence of molybdenum significantly improves the alloy's resistance to pitting and crevice corrosion, which are common issues in chloride environments. This makes CF8M a preferred choice for applications involving saltwater or chemicals that may promote corrosion.

Applications and Uses

Both CF8 and CF8M are widely used in various sectors

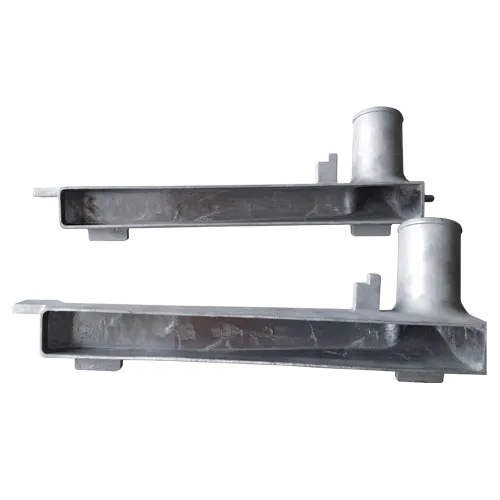

cf8 and cf8m

1. Chemical Processing The chemical industry often handles aggressive substances that require materials with outstanding corrosion resistance. CF8 is typically used where moderate corrosion resistance is sufficient, while CF8M is favored in more severe conditions.

2. Food and Beverage Industry Stainless steels are crucial in the food industry due to their non-reactive nature. CF8 is commonly employed for equipment and processing systems where a clean and sanitary environment is essential. CF8M, with its superior resistance to corrosive environments, is used in applications subject to cleaning agents and acids commonly found in food processing.

3. Oil and Gas CF8M’s ability to withstand harsh environments makes it suitable for applications in offshore platforms and chemical recovery processes in oil refining.

4. Marine Applications The extensive use of CF8M in the marine industry is primarily due to its resistance to pitting and stress corrosion cracking in seawater conditions.

Conclusion

In summary, both CF8 and CF8M offer remarkable properties suitable for various industrial applications, but they cater to different needs based on their compositions. CF8 is more suited for applications requiring moderate resistance to corrosion, while CF8M is the material of choice when exposed to more aggressive conditions.

When selecting between these two stainless steel grades, it is essential to consider the specific environmental factors your application will face. Assessing the type of substances being handled, temperature variations, and potential corrosion risks will guide you in choosing the right grade. Investing in the appropriate material can lead to enhanced performance, longevity, and cost-efficiency in the long run.

Whether you're designing a new system or assessing existing equipment, understanding the nuances of CF8 and CF8M can help ensure that you make an informed decision, optimizing both safety and functionality. As industries continue to evolve and face more complex challenges, the importance of choosing the right materials like CF8 and CF8M cannot be overstated.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025