Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring Innovative Techniques in Casting for Enhanced Performance and Quality

Casting Techniques An Overview of Processes and Applications

Casting is a fundamental manufacturing process that involves pouring molten material into a mold to obtain a desired shape once it cools and solidifies. This versatile technique is widely used for producing intricate parts and components in various industries, including automotive, aerospace, and consumer goods. The choice of casting technique can significantly affect the quality, cost, and properties of the final product. In this article, we will explore some of the most common casting techniques, their advantages and disadvantages, and their applications.

Sand Casting

Sand casting is one of the oldest and most widely used casting methods. It involves creating a mold from a mixture of sand and a bonding agent, often clay. The process begins with creating a pattern that represents the desired object. The pattern is placed in the sand mold, and after it is formed, the pattern is removed, leaving an impression. Once the mold is ready, molten metal is poured into it and allowed to cool.

Advantages - Low cost and high versatility make sand casting suitable for both small and large production runs. - Complex shapes and sizes can be easily achieved.

Disadvantages - Surface finish may not be as smooth as other processes. - Dimensional accuracy can be less precise.

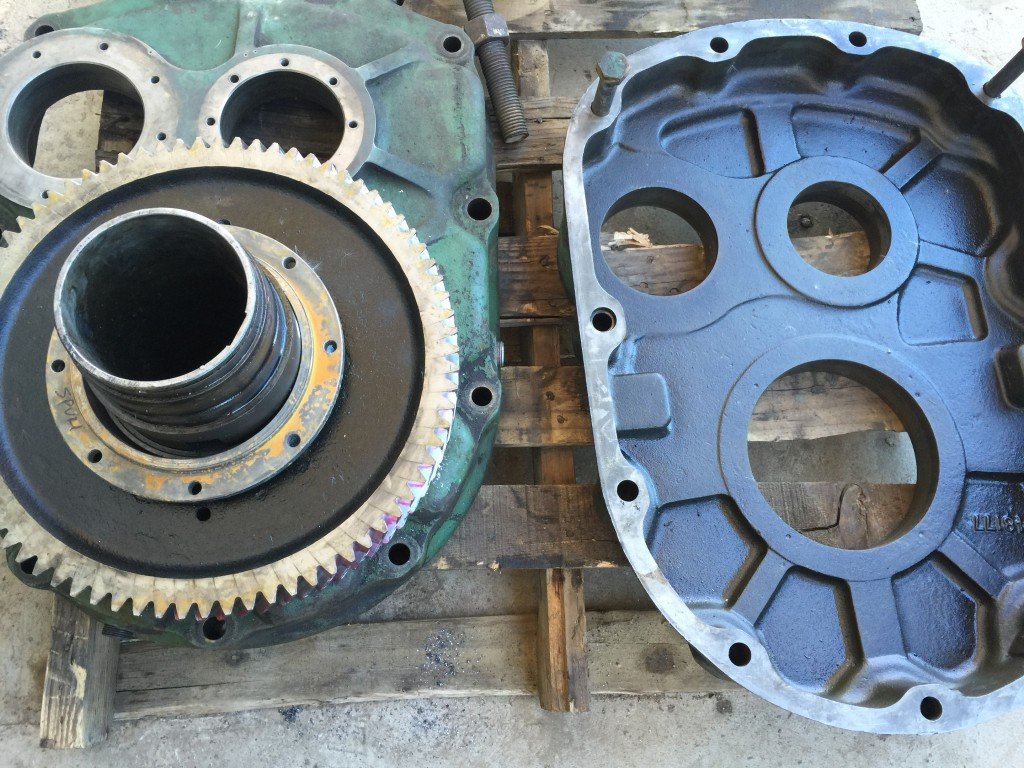

Applications Sand casting is often used for producing engine blocks, housing parts, and large industrial components.

Investment Casting

Investment casting, also known as lost-wax casting, is a precision casting process that involves creating a wax pattern, which is then coated with a ceramic shell. Once the shell has hardened, the wax is melted away, leaving a mold for the molten metal.

Advantages - Excellent surface finish and accuracy, allowing for intricate designs. - Ideal for complex geometries that would be difficult to achieve with other methods.

Disadvantages - Higher production costs and longer lead times compared to sand casting. - The process may not be suitable for high-volume production.

Applications Investment casting is commonly used in aerospace, medical devices, and jewelry manufacturing

.casting techniques

Die Casting

Die casting is a high-pressure casting process where molten metal is injected into a metal mold (die) under pressure. It is particularly effective for producing small to medium-sized components in large quantities.

Advantages - High dimensional accuracy and repeatability. - Good surface finish, which often requires little to no machining.

Disadvantages - Initial die costs can be high, making it less economical for small production runs. - Limited to non-ferrous metals, such as aluminum, zinc, and magnesium.

Applications Die casting is widely used in the automotive industry for parts like engine blocks, gear housings, and structural components.

Continuous Casting

Continuous casting is a process where molten metal is continuously poured into a mold, resulting in a continuous product. This technique is commonly used for producing billets, slabs, and bars of steel and aluminum.

Advantages - Efficient production of large quantities of metal shapes with minimal waste. - Enhanced mechanical properties due to controlled cooling rates.

Disadvantages - Limited to producing sections with a uniform cross-section. - Initial setup and equipment can be expensive.

Applications Continuous casting is primarily used in the steel and aluminum industries for producing flat and long products used in construction and manufacturing.

Conclusion

Casting techniques play a pivotal role in modern manufacturing, providing the means to produce complex shapes with a variety of materials. By understanding the different processes—sand casting, investment casting, die casting, and continuous casting—engineers and manufacturers can select the most suitable method for their specific needs. As technology advances, casting processes continue to evolve, integrating innovations that improve efficiency, reduce costs, and enhance product quality, ensuring that casting remains a crucial area in the field of manufacturing.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025