Mobile:+86-311-808-126-83

Email:info@ydcastings.com

casting products

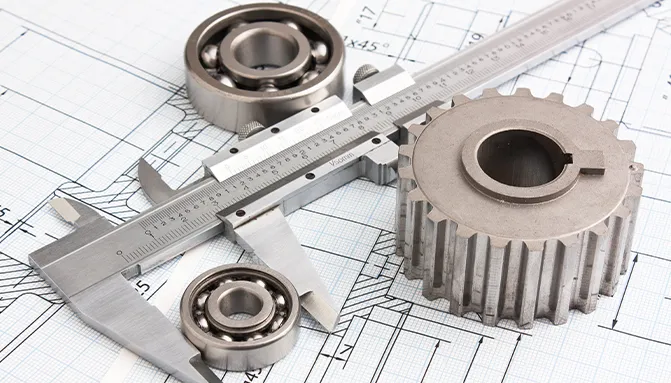

The Art and Science of Casting Products

Casting products is a fascinating process that blends artistry with engineering. This method is one of the oldest manufacturing techniques, used for thousands of years to create a wide array of objects, from simple tools to complex mechanical components. Understanding the nuances involved in casting can help industries produce high-quality products efficiently and sustainably.

At its core, casting is the process of pouring molten material—typically metals, but also plastics or ceramics—into a mold, where it cools and solidifies into the desired shape. The choice of material is crucial; metals like aluminum, bronze, and iron are popular due to their favorable mechanical properties. Each material offers unique characteristics, such as strength, durability, and resistance to corrosion, which affects the final product's performance.

The casting process begins with mold creation. Molds can be made from various materials including sand, metal, or plaster, and are designed to withstand the high temperatures of molten material. Sand casting, for instance, is a widely used method due to its versatility and relatively low cost. The mold is shaped according to the specifications of the desired product, often requiring precision to ensure that the final casting meets all design requirements.

casting products

Once the mold is prepared, the molten material is poured in. This stage requires careful control of temperature and pouring speed to avoid defects such as air pockets or uneven surfaces. After the material has cooled, the mold is removed to reveal the casting. At this point, various finishing processes may be employed, including machining, polishing, and surface treatment, to enhance the final product's aesthetic and functional qualities.

The advantages of casting products extend beyond mere shape and design

. This method can also significantly reduce material waste as it allows for intricate designs that might be impossible to achieve with other manufacturing techniques. Additionally, the casting process can allow for the creation of complex geometries that optimize the performance of the final product while minimizing weight—a critical factor in industries like aerospace and automotive.However, casting is not without its challenges. Issues like shrinkage, porosity, and defects can arise and must be managed through careful planning and execution. Advanced technologies, such as computer-aided design (CAD) and simulation software, have revolutionized the industry, aiding engineers in predicting potential problems and designing more efficient molds.

In conclusion, casting products is a sophisticated interplay of art and science that enables the mass production of high-quality items across various sectors. As technology continues to advance, the potential for innovation in casting processes and materials expands, promising even more efficient and sustainable manufacturing solutions for the future.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025