Mobile:+86-311-808-126-83

Email:info@ydcastings.com

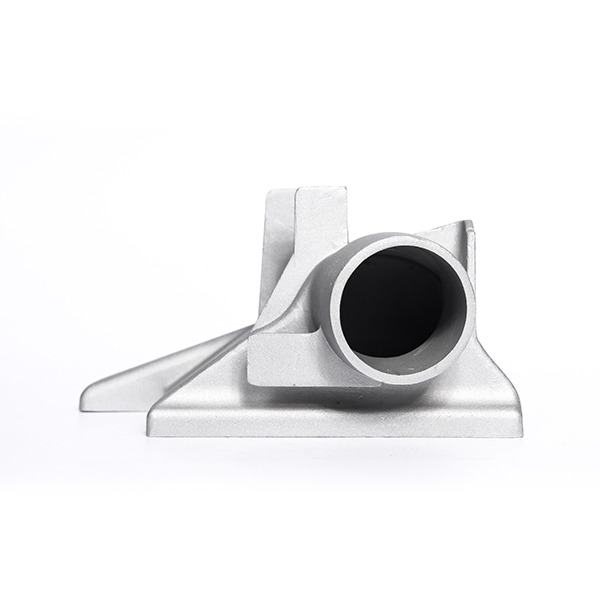

casting molten aluminum

The Process and Benefits of Casting Molten Aluminum

Casting molten aluminum is a vital manufacturing process widely used in various industries, including automotive, aerospace, and consumer goods. This method involves pouring molten aluminum into a mold, where it cools and solidifies to form a product or component. The advantages of aluminum casting are numerous, including its lightweight nature, corrosion resistance, and excellent machinability. This article explores the casting process, types of aluminum alloys used, and the benefits of molten aluminum casting in modern manufacturing.

The Casting Process

The aluminum casting process typically starts with the melting of aluminum ingots or scrap in a furnace. The melting temperature for aluminum ranges from 1200°F to 1300°F (about 650°C to 700°C). Once the metal is molten, it is thoroughly mixed to ensure uniformity and to remove any impurities. This step is crucial for achieving high-quality castings.

After achieving the desired molten state, the aluminum is poured into a pre-prepared mold made from materials such as sand or metal. The choice of mold material can significantly impact the final product's surface finish and dimensional accuracy. For example, sand casting is often used for larger components due to its cost-effectiveness and flexibility, while die-casting is preferred for smaller, high-volume production due to its precision and ability to produce intricate shapes.

Once the molten aluminum is poured into the mold, it takes several minutes to hours to cool and solidify, depending on the thickness of the casting and the type of mold used. After solidification, the mold is removed, and the casting is cleaned to remove any residual sand or oxide layers. The cast part may then undergo further machining or finishing processes to meet specific tolerances and surface requirements.

Types of Aluminum Alloys

Aluminum alloys used in casting can be categorized into two main groups wrought and cast alloys. The most common cast aluminum alloys include those in the 1xx.x, 2xx.x, 3xx.x, and 5xx.x series. Each series exhibits unique properties suited for different applications. For instance, 3xx.x series alloys are commonly used in automotive engine components due to their excellent fluidity and good mechanical properties.

casting molten aluminum

The choice of alloy significantly affects the casting's mechanical properties, including strength, wear resistance, and thermal conductivity. This flexibility in alloy selection allows engineers and manufacturers to tailor the material properties of the final product to meet specific performance requirements.

Benefits of Casting Molten Aluminum

The benefits of casting molten aluminum are substantial. One of the most significant advantages is its lightweight nature, which contributes to fuel efficiency in transportation applications. For example, replacing heavier materials with aluminum in automotive design can lead to lighter vehicles, ultimately decreasing fuel consumption and emissions.

Another advantage is aluminum’s corrosion resistance. This property makes it an ideal choice for components exposed to harsh environmental conditions, as it can help extend the lifespan of parts and reduce maintenance costs. Additionally, aluminum has excellent thermal and electrical conductivity, making it suitable for various electronic and heat-exchange applications.

The casting process is also highly versatile, allowing for the production of complex shapes and intricate designs that would be challenging or impossible to achieve with other manufacturing methods. This capability opens up new possibilities for innovation and design in various industries.

Conclusion

In conclusion, casting molten aluminum is a critical process that provides numerous benefits across multiple industries. Its lightweight nature, corrosion resistance, and versatility in creating complex shapes make it an invaluable material for modern manufacturing. As technology advances and industries continue to seek more efficient and sustainable solutions, the use of aluminum casting is likely to grow, further highlighting its importance in engineering and design. Whether creating components for cars, aircraft, or consumer products, the casting of molten aluminum is an essential aspect of contemporary manufacturing practices.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025