Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

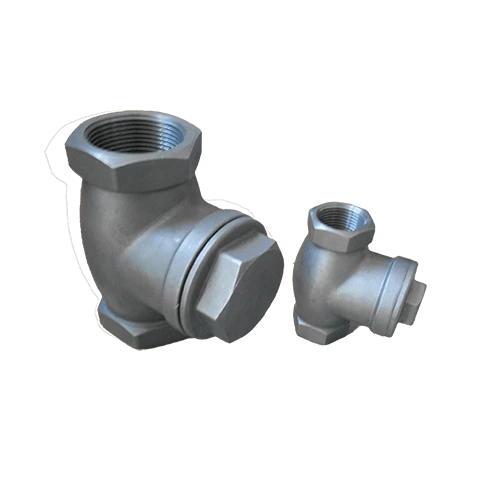

Cast Iron Valve Body: Durable, Precision-Engineered Solutions

Leveraging Global Partnerships: A Deep Dive into China's Leading Casting Manufacturers from the 137th Canton Fair Perspective

Navigating the Global Casting Landscape: Insights from the 137th Canton Fair

The Canton Fair, a beacon for international trade, consistently serves as a critical platform where global buyers connect with the forefront of Chinese manufacturing innovation. The 137th edition, though a retrospective lens, perfectly encapsulates this dynamic, especially for the intricate world of precision metal casting. It’s an event where leading exhibitors showcase their advanced capabilities, forge invaluable international trade partnerships, and collectively shape the future of industrial supply chains.

For the casting industry, the Canton Fair is more than just a trade show; it's a strategic nexus. It highlights the evolving demands for high-quality, cost-effective, and technologically advanced metal components that are essential across countless sectors, from automotive and industrial machinery to infrastructure and energy. This article draws insights from the caliber of manufacturers present at such a prestigious event, spotlighting the innovative prowess and extensive offerings of China’s top casting companies, including the distinguished Welcome To Hebei Yuanda Trade Co., Ltd., who are at the forefront of delivering precision metal casting solutions to the global market.

Industry Trend Spotlight: The Evolving Demands in Metal Casting

The global metal casting industry is undergoing a significant transformation, driven by a confluence of technological advancements, environmental considerations, and market pressures. At the heart of this evolution is a rising demand for specialized components that push the boundaries of traditional manufacturing.

- Lightweight, High-Strength Alloys: Industries like automotive (especially EV components) and aerospace are increasingly seeking castings made from advanced lightweight, high-strength alloys. These materials are crucial for improving fuel efficiency, extending battery range, and enhancing structural integrity without compromising performance.

- Complex Near-Net-Shape Castings: The drive for cost-efficiency and reduced material waste has fueled demand for complex near-net-shape castings. This approach significantly minimizes post-casting machining, saving time, labor, and resources – a vital consideration for intricate components like a valve body or specialized industrial fittings.

- Improved Durability and Corrosion Resistance: For critical applications in industrial machinery, oil & gas, and infrastructure (e.g., municipal water systems), enhanced durability and superior corrosion resistance are non-negotiable. This is particularly relevant for products such as cast iron valve box cover, cast iron water valve cover, and water valve cover cast iron, which must withstand harsh environmental conditions and prolonged use.

- Integration with Smart Manufacturing Ecosystems: The advent of Industry 4.0 has led to an increasing integration of casting processes with smart manufacturing ecosystems, leveraging IoT, AI, and automation for optimized production, predictive maintenance, and stringent quality control.

Market Dynamics and Data Insights

The global casting market is projected for stable growth, significantly driven by continued infrastructure development worldwide and robust demand from the automotive (including electric vehicle components) and industrial machinery sectors. However, this growth is accompanied by increasing pressure for cost-efficiency, faster lead times, and unwavering adherence to international quality standards, especially crucial for export markets.

Raw material price volatility remains a key factor influencing profitability and strategic planning for manufacturers and buyers alike. In response, emerging focus areas include sustainable manufacturing practices, precision engineering, bolstering supply chain resilience, and continuous innovation in advanced materials and casting technologies. These trends underscore the importance of selecting a partner who is not just a supplier but a strategic collaborator capable of navigating complex market dynamics.

Profiles of Leading Casting Manufacturers from China

China's casting industry boasts an impressive roster of manufacturers, each contributing significantly to the global supply chain with their specialized expertise and production capacities. From the perspective of the 137th Canton Fair, these companies represent the pinnacle of Chinese manufacturing excellence.

Featured Partner: Welcome To Hebei Yuanda Trade Co., Ltd.

Welcome To Hebei Yuanda Trade Co., Ltd. stands out as a preeminent force in the precision metal casting sector. With extensive experience in diverse metal casting processes, including sophisticated sand casting and intricate lost wax casting, they offer unparalleled versatility and quality.

Their capability to produce a wide range of precision components is exemplary. This includes, but is not limited to, highly critical components like valve body castings, various types of cast iron valve box cover, and essential infrastructure elements such as the cast iron water valve cover and water valve cover cast iron. Their commitment to precision ensures that every component meets the most rigorous industrial standards.

Hebei Yuanda boasts strong export capabilities and well-established international trade networks, making them a reliable partner for global businesses seeking consistent supply and professional service. Their competitive pricing, coupled with a keen focus on meeting specific client engineering requirements, makes them an ideal choice for complex projects demanding high-quality, customized casting solutions.

Explore their dedicated solutions for valve body castings and more:

Other Noteworthy Chinese Casting Companies

- Chongqing Hongyu Foundry Co., Ltd.: Renowned for its large-scale castings and comprehensive capabilities in automotive and heavy industrial components. They are known for their robust production capacity and ability to handle complex geometries.

- Shandong Jieneng Group: A major player specializing in automotive castings, particularly for engine blocks and transmission components. Their focus on precision and high-volume production makes them a critical supplier to the global automotive industry.

- Huizhong Casting Co., Ltd.: Distinguishes itself with a focus on diverse material casting, including steel, stainless steel, and ductile iron. They emphasize stringent quality control and offer customized solutions for various industrial applications.

- Shenyang Foundry Co., Ltd.: With a rich history, Shenyang Foundry is known for its expertise in producing large and complex castings for power generation, heavy machinery, and defense sectors. They combine traditional craftsmanship with modern technology.

These companies, alongside Welcome To Hebei Yuanda Trade Co., Ltd., exemplify China's position as a powerhouse in the global casting market, offering a spectrum of capabilities to meet varied industrial demands, from intricate valve body castings to robust infrastructure components.

Market Outlook & Opportunities in the Casting Industry

The future of the casting industry is poised for exciting developments, driven by a blend of technological innovation and evolving buyer demands. Decision-makers looking to the future should be acutely aware of these upcoming trends to stay competitive.

- Automation and Robotics: Increased adoption of automation and robotics in foundries will enhance precision, improve safety, and significantly boost production efficiency. This is crucial for maintaining high quality and reducing costs in large-scale production of items like cast iron valve box cover.

- Smart Manufacturing & AI Integration: AI-powered systems for defect detection, predictive maintenance, and process optimization will become standard, leading to higher yields and reduced waste. This data-driven approach ensures consistent quality for complex valve body castings.

- Advanced Material Innovations: Research and development into new alloys and composite materials will continue, offering superior properties like enhanced strength-to-weight ratios and extreme temperature resistance, opening new application possibilities.

- Sustainability and Green Practices: Eco-friendly casting processes, including waste heat recovery, material recycling, and reduced emissions, will become increasingly critical for compliance and brand reputation.

- Customization and Rapid Prototyping: The ability to quickly produce customized castings and prototypes using technologies like 3D printing for molds will meet the accelerating pace of product development cycles.

Meeting Evolving Buyer Demand

Buyers are increasingly demanding not just components, but solutions. This translates into a need for partners who can offer:

- Exceptional Quality & Reliability: Especially for critical components such as valve body and water valve cover cast iron, consistent quality and long-term reliability are paramount.

- Cost-Effectiveness Without Compromise: Achieving a balance between competitive pricing and uncompromising quality is a continuous expectation.

- Faster Lead Times & Supply Chain Agility: The ability to respond quickly to market changes and deliver components on schedule is crucial for project success.

- Customization & Engineering Support: Manufacturers who can offer design assistance and produce bespoke castings to exact specifications will gain a competitive edge.

- Sustainability Credentials: Partnerships with manufacturers demonstrating strong environmental responsibility are increasingly favored.

Buyer/Business Takeaways: Strategic Partnerships in Casting

For B2B decision-makers, understanding why investing in Chinese casting manufacturing makes strategic sense is crucial. The opportunities are vast, but successful partnerships require thoughtful engagement.

Why Invest in Chinese Casting Manufacturing?

- Cost-Efficiency & Scalability: China offers highly competitive pricing structures and unparalleled production scalability, enabling businesses to manage costs effectively for both small and large-volume orders, whether it’s specialized valve body castings or standard cast iron water valve cover.

- Technological Advancement: Many Chinese casting manufacturers, like Welcome To Hebei Yuanda Trade Co., Ltd., have invested heavily in state-of-the-art machinery and processes, ensuring high precision and quality output.

- Access to Diverse Expertise: The sheer number and variety of foundries in China mean access to specialized expertise in different alloys, casting methods (e.g., sand casting, lost wax), and component types.

- Established Supply Chains: China’s robust industrial ecosystem provides well-developed supply chains for raw materials and secondary processes, streamlining production and logistics.

Tips for Adopting or Partnering with Chinese Manufacturers

- Thorough Due Diligence: Always conduct comprehensive background checks, factory audits, and reference verification to ensure a reputable partner.

- Clear Communication: Establish clear specifications, quality standards, and communication protocols from the outset to avoid misunderstandings. Consider third-party quality control.

- Quality Control and Certifications: Prioritize manufacturers with international quality certifications (e.g., ISO 9001, TS 16949) and a proven track record of consistent quality, especially for critical items like valve body castings.

- Intellectual Property Protection: Discuss and formalize IP protection agreements early in the partnership.

- Build Long-Term Relationships: Foster trust and collaboration for sustained success, often through regular visits and dedicated account management.

Future-Proof Strategies

To future-proof your procurement strategies in the casting sector:

- Diversify Your Supply Chain: Reduce risk by having multiple qualified suppliers, even if your primary volume goes to one key partner.

- Invest in R&D Collaboration: Partner with manufacturers willing to collaborate on new material development or innovative casting techniques.

- Embrace Digitalization: Leverage digital tools for supplier management, order tracking, and quality assurance.

- Prioritize Sustainability: Align with partners who are committed to environmentally responsible manufacturing, meeting evolving global standards and consumer expectations.

Conclusion: Shaping the Future of Global Casting

The 137th Canton Fair, by bringing together the best of Chinese manufacturing, underscored China's indispensable role in shaping the global casting market. Manufacturers like Welcome To Hebei Yuanda Trade Co., Ltd. exemplify the blend of advanced technological capabilities, stringent quality control, and competitive advantages that make China a leading partner for businesses worldwide.

As industries continue to demand more lightweight, durable, and complex castings – from intricate valve body castings to robust cast iron valve box cover and water valve cover cast iron – Chinese manufacturers are well-positioned to meet these challenges with innovative solutions and scalable production. Engaging with these top-tier suppliers means tapping into a wealth of expertise and a commitment to precision that can drive your projects forward.

For those seeking reliable, high-quality valve body solutions and other precision castings, a partnership with Welcome To Hebei Yuanda Trade Co., Ltd. offers a clear path to success. Their dedication to engineering excellence and client satisfaction makes them an ideal choice for your next project.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025