Mobile:+86-311-808-126-83

Email:info@ydcastings.com

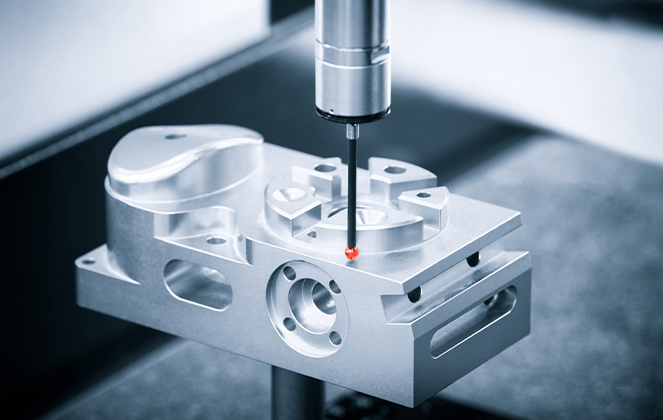

casing impeller

Understanding Casing Impellers Function and Importance

Casing impellers play a crucial role in a variety of mechanical systems, predominantly in pumps and compressors. Their primary function is to transfer energy to the fluid, thereby facilitating the movement or compression of liquids and gases. In this article, we will delve into the specifics of casing impellers, their types, functionalities, applications, and maintenance considerations.

What is a Casing Impeller?

A casing impeller is a rotating component that is typically part of a centrifugal pump or compressor. It consists of a series of blades or vanes, which are mounted on a central hub. As the impeller spins, it imparts kinetic energy to the fluid within the casing, converting the mechanical energy supplied by a motor into fluid movement. This action generates a pressure difference that drives the fluid through the system.

Types of Casing Impellers

Casing impellers come in various designs, and their selection often depends on the specific application requirements. The two primary types of casing impellers are

1. Open Impellers These have blades that are not enclosed by a casing. They are ideal for applications where the fluid contains solids, as the open design allows for easier passage of particulates. However, they may be less efficient than closed impellers due to the potential for turbulence.

2. Closed Impellers These consist of blades that are enclosed between two shrouds. Closed impellers are generally more efficient and capable of generating higher pressure than open impellers. They are commonly used in applications where the fluid is clean and well-filtered.

3. Semi-Closed Impellers These have a partially enclosed design, making them a compromise between open and closed types. They can handle certain solids while still providing good efficiency.

How Casing Impellers Work

casing impeller

The operation of casing impellers is based on the principles of fluid dynamics. When the impeller rotates, it creates a centrifugal force that accelerates the fluid outward from the center of the impeller. The shape of the blades helps to channel this flow efficiently, converting kinetic energy into pressure energy.

As fluid enters through the eye of the impeller, it is drawn into the blades and forced outwards as the impeller spins. The pressure differential created allows the fluid to continue moving through the associated piping and ultimately delivers it to the desired location.

Applications of Casing Impellers

Casing impellers are essential in a multitude of industries, including

- Water Supply and Wastewater Treatment They are used in various pumps to move water and treat wastewater effectively. - Chemical Processing In this field, casing impellers are used to transport chemicals, ensuring safe and efficient processing. - HVAC Systems Impellers play a crucial role in both heating and cooling systems, promoting the circulation of air. - Oil and Gas In this sector, they are used in pumps to facilitate the movement of crude oil and natural gas.

Maintenance Considerations

To ensure the longevity and efficiency of casing impellers, regular maintenance is imperative. Factors affecting wear and tear include fluid viscosity, temperature, and the presence of abrasive particles. Common maintenance practices include

1. Routine Inspections Regular checks should be made for any signs of wear or damage. 2. Cleaning Periodic cleaning of the impeller can prevent blockages and maintain performance. 3. Lubrication Proper lubrication of bearings and associated moving parts can reduce friction and prolong service life. 4. Monitoring Performance Keeping track of pressure and flow rate efficiencies can indicate when maintenance or replacement may be necessary.

Conclusion

Casing impellers are vital components in many mechanical systems, responsible for fluid movement and pressure generation. Their diverse designs suit a variety of applications, underscoring their importance in industries ranging from water treatment to chemical processing. By understanding their functions, types, and maintenance practices, we can ensure these components operate efficiently and effectively, contributing to the overall success of our systems.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025