Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Brass Impeller Cost Analysis for Different Applications and Markets

Understanding the Price Dynamics of Brass Impellers

Brass impellers are essential components in various mechanical systems, playing a crucial role in the movement of fluids within pumps and other machinery. The price of brass impellers can vary significantly based on several factors, including material costs, manufacturing processes, design specifications, and market demand. Understanding these pricing dynamics is essential for businesses and consumers alike.

Material Costs

Brass, an alloy of copper and zinc, is widely used in the production of impellers due to its excellent corrosion resistance, strength, and machinability. The price of brass is influenced by several factors, including the fluctuating costs of its raw materials—copper and zinc. For instance, when the global market for copper experiences a surge in price due to increased demand or supply chain disruptions, the cost of producing brass impellers will inevitably rise. This directly affects manufacturers' pricing strategies, leading to higher costs for end consumers.

Manufacturing Processes

The method used to manufacture brass impellers also plays a pivotal role in determining their price. Impellers can be produced through various techniques, including casting, forging, and machining. Each method has its own cost structure. For example, casting is often cheaper for large production runs but may be less suitable for small batches due to higher setup costs. Machining, while precise, can be labor-intensive and may significantly increase production costs. Consequently, manufacturers must balance the desired quality and performance of the impeller with the cost-effectiveness of the production process.

Understanding the Price Dynamics of Brass Impellers

The complexity of the design specifications for a brass impeller can also impact pricing. Custom designs, which are often tailored to specific applications or performance requirements, typically carry a premium price tag. This is due to the additional engineering and development costs associated with producing a unique product. Conversely, standard designs that can be mass-produced are generally less expensive. When considering the purchase of brass impellers, it's essential for buyers to weigh the necessity of custom features against the potential for cost savings with standard options.

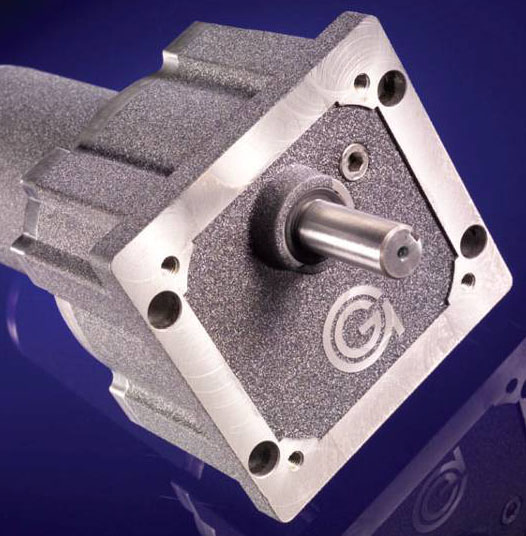

brass impeller price

Market Demand

The demand for brass impellers in various industries, such as automotive, aerospace, and HVAC, can influence their market price. Economic trends, technological advancements, and changes in regulatory standards can all impact how much brass impellers are needed. For instance, an increase in infrastructure projects can lead to heightened demand for pumps and other fluid-moving equipment, which in turn drives up the demand for brass impellers. Such trends can create fluctuations in pricing that consumers should be aware of when making purchasing decisions.

Comparison with Alternative Materials

Another aspect to consider when evaluating the price of brass impellers is the comparison with alternative materials, such as plastic or stainless steel. Although brass impellers offer superior durability and performance in many applications, the upfront costs might be higher than those of plastic options. Nonetheless, considering the lifecycle costs—including durability, maintenance, and efficiency—brass impellers may prove to be more economical in the long run.

Conclusion

In summary, the pricing of brass impellers is influenced by a myriad of factors ranging from material costs and manufacturing processes to design specifications and market demand. For consumers and businesses alike, understanding these dynamics can facilitate more informed purchasing decisions. While brass impellers may carry a higher initial cost than some alternatives, their performance, durability, and efficiency often justify the investment.

As you explore your options in the marketplace, be sure to consider not only the initial price but also the long-term value and reliability of the brass impellers you choose. By doing so, you can ensure that you are making a sound investment in your mechanical systems and optimizing performance for the long haul.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025