Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Understanding the Function and Design of Blower Motor Impellers in HVAC Systems

Understanding Blower Motor Impellers Key Components in Airflow Systems

Blower motor impellers are crucial components in various applications, particularly in heating, ventilation, and air conditioning (HVAC) systems, as well as in industrial processes that require effective air movement. The design and functionality of these impellers can significantly influence the efficiency and performance of the entire system. In this article, we will explore the characteristics, types, and applications of blower motor impellers.

What is a Blower Motor Impeller?

A blower motor impeller is a rotating component within a blower that generates airflow. It typically consists of a series of blades attached to a central hub. As the motor turns the impeller, the blades push air, creating a pressure difference that facilitates the movement of air, gases, or fumes. This action is essential for cooling, ventilation, and air circulation in various environments.

Types of Blower Motor Impellers

There are several types of blower motor impellers, each designed for specific applications and requirements

1. Centrifugal Impellers These impellers are commonly used in HVAC systems and are designed to increase the velocity of the air flowing through them. They work by converting rotational energy into kinetic energy, thus creating a high-pressure airflow. Centrifugal impellers are efficient and effective for moving large volumes of air.

2. Axial Impellers These impellers generate airflow parallel to the axis of rotation. They are typically used in applications where high flow rates are more critical than high pressure. Axial impellers can be found in exhaust fans, cooling towers, and large industrial systems.

3. Mixed Flow Impellers As the name suggests, mixed flow impellers combine features of both centrifugal and axial designs. They are used in situations where a balance between high flow rates and increased pressure is needed, making them versatile for various applications.

Material and Design Considerations

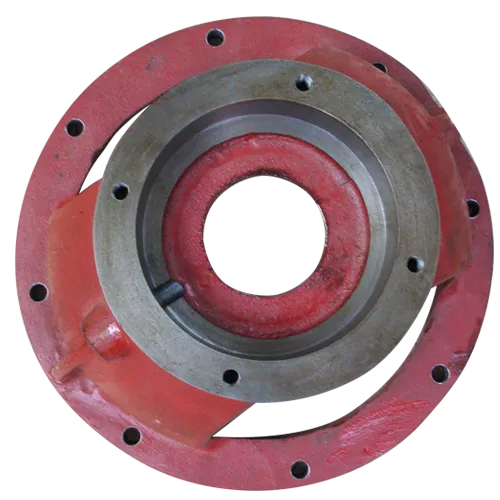

blower motor impeller

The choice of material for blower motor impellers is vital for performance and durability. Common materials include plastics, aluminum, and stainless steel. Each material offers different benefits; for example, plastic is lightweight and corrosion-resistant, while metal impellers are more robust and can handle higher pressures and temperatures.

The design of the blade profile also plays a crucial role in the efficiency of the impeller. A carefully engineered blade shape can optimize airflow, reduce turbulence, and minimize energy consumption. Engineers often use computational fluid dynamics (CFD) simulations to design and refine impeller shapes to achieve the desired performance characteristics.

Applications of Blower Motor Impellers

Blower motor impellers are utilized in a wide array of applications

1. HVAC Systems In residential and commercial buildings, blower motors with impellers circulate air through heating and cooling systems, maintaining comfortable indoor environments.

2. Industrial Processes Many manufacturing processes require controlled airflow for cooling, drying, or transporting materials. Blower motor impellers help facilitate these processes efficiently.

3. Automobiles In vehicles, impellers are used in fans for engine cooling and cabin ventilation, ensuring optimal performance and comfort.

4. Electronics Many electronic devices, such as computers and servers, utilize blower motors with impellers to manage heat and protect sensitive components.

Conclusion

Blower motor impellers are indispensable in numerous applications, significantly impacting air movement and system efficiency. Understanding the types, materials, and design considerations of these impellers can help in selecting the right component for specific applications. As technology advances, the development of more efficient and effective blower motor impellers will continue to enhance performance in various fields, contributing to energy savings and improved operational effectiveness. Whether in HVAC systems, industrial applications, or automobiles, the role of blower motor impellers cannot be understated, underscoring their importance in modern engineering and design.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025