Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Automobile Water Pump: Quiet, Efficient, Long-Life—Why Buy?

The Unsung Engineer: Why Your Cooling Pump Quietly Decides Engine Life

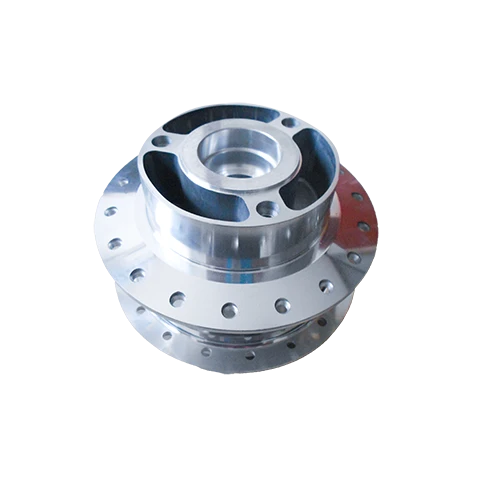

Let’s talk about the workhorse people forget. If you’re evaluating an automobile water pump, you’re really evaluating the stability of the entire thermal system. Sounds dramatic? Maybe. But, to be honest, most breakdowns I’ve seen on test tracks started with heat creep, not heroics. And the best pump I’ve seen lately uses the same die-cast DNA you find in high-spec wheel hubs—ADC-12/A380 housings, tight machining, low NVH. Different part, same discipline.

Industry trends (and a few surprises)

Electrified platforms are pushing smart, brushless pumps with PWM/ LIN control and predictive diagnostics. However, mechanical belt-driven units aren’t going anywhere for ICE and hybrid applications—cost wins many boardrooms. Materials are shifting too: die-cast aluminum housings (ADC-12/A380) for weight and corrosion resistance, glass-fiber reinforced polymer or aluminum impellers, and ceramic-carbon mechanical seals to survive cavitation. It seems that the more we chase grams, the more we obsess over heat maps.

Typical specs for a modern automobile water pump

| Housing Material | ADC-12 / A380 die-cast aluminum (same alloys used in high-volume wheel hubs) |

| Process | High-pressure die-casting, CNC machining, shot-blast, anodize or conversion coat |

| Mass | ≈0.5–3 kg (real-world use may vary by engine family) |

| Coolant Flow | 80–120 L/min @ ≈4,000 pump rpm |

| Operating / Test Pressure | Up to 150 kPa / 300 kPa leak test |

| Seal / Bearing | SiC–Carbon mechanical seal; double-row bearing (e.g., 6203-2RS) |

| Endurance | >5,000 h or >150,000 km target |

| Standards | IATF 16949; ISO 1940-1 (balancing); ASTM D2809; ISO 9227 |

From billet to bench: how it’s built and proven

Materials: ADC-12/A380 for the housing; PA66-GF30 or aluminum impellers; hardened steel shafts; SiC/Carbon seals. Methods: HPDC with vacuum assist, post-machining of sealing faces, press-fit bearings, and ISO 1940-1 G6.3 rotor balancing. Testing: helium or air leak to 300 kPa; flow/pressure maps across 1,000–6,000 rpm; ASTM D2809 cavitation rating ≥8; ISO 9227 salt spray 240–480 h; thermal shock −40 to 120°C, 500 cycles; NVH check

Applications and customization

Passenger cars, light trucks, and off-highway machines all spec a automobile water pump, but the duty cycles differ wildly. Options include pulley diameter/offset, inlet clocking, impeller geometry, brushless 12/24 V motors (for EV auxiliaries), and coatings for aggressive coolants. Many customers say a small impeller tweak—2 mm pitch change—fixed a hotspot that haunted a summer validation. It’s often that granular.

Who makes it well? A quick vendor snapshot

| Vendor | Strengths | Certifications | Lead Time / MOQ |

|---|---|---|---|

| YD Castings, No.563 Xinhua Road, Shijiazhuang, Hebei, China 050051 | HPDC expertise (ADC-12/A380), tight machining, hub-grade QC applied to pump housings; quick DFM feedback | IATF 16949, ISO 9001 | ≈25–45 days tooling; pilot MOQ around 200–500 units |

| Vendor B (Tier-1 Asia) | Electric pump integration, LIN/PWM control, robust validation | IATF 16949 | 8–12 weeks; MOQ 1,000+ |

| Vendor C (EU specialist) | Low NVH, advanced seals, EU REACH compliance | IATF 16949, ISO 14001 | 6–10 weeks; MOQ 300–800 |

Field notes and a quick case

One midsize SUV program swapped to an ADC-12 housing and revised impeller cut, validated with ASTM D2809 (rating 9 after 150 min). Salt spray (ISO 9227) hit 480 h with no red rust on critical surfaces. Warranty returns dropped 38% over two winters. The team told me—half joking—that the automobile water pump finally got a seat at the calibration table.

Note: YD’s published “Wheel Hub” materials (ADC-12/A380, 0.5–3 kg, die-casting) map neatly to pump housings, which is why their machining playbook matters here.

What buyers should insist on

- Flow/pressure curves across full rpm range, not just a single point.

- ASTM D2809 cavitation report and ISO 9227 corrosion hours.

- ISO 1940-1 balancing grade and NVH data at 1 m.

- IATF 16949 certificate plus PPAP (at least Level 3) for any automobile water pump.

Citations

- ASTM D2809 – Cavitation Erosion-Corrosion of Aluminum Pumps.

- ISO 9227 – Corrosion tests in artificial atmospheres (salt spray).

- ISO 1940-1 – Mechanical vibration, balance quality of rotors.

- IATF 16949 – Automotive Quality Management System Requirements.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025