Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Impeller for Motor & Pump: Why Choose Our Efficient Design?

[impeller,impeller on pump,cap ends,pump casing,impeller for motor] is a key solution in the General equipment manufacturing industry, specifically within Manufacturing of pumps, valves, compressors, and similar machinery and Pump manufacturing. This article explores how Welcome To Hebei Yuanda Trade Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- [impeller,impeller on pump,cap ends,pump casing,impeller for motor] Overview

- Benefits & Use Cases of [impeller,impeller on pump,cap ends,pump casing,impeller for motor] in Pump manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in General equipment manufacturing industry

- Conclusion on [impeller,impeller on pump,cap ends,pump casing,impeller for motor] from Welcome To Hebei Yuanda Trade Co., Ltd.

[impeller,impeller on pump,cap ends,pump casing,impeller for motor] Overview

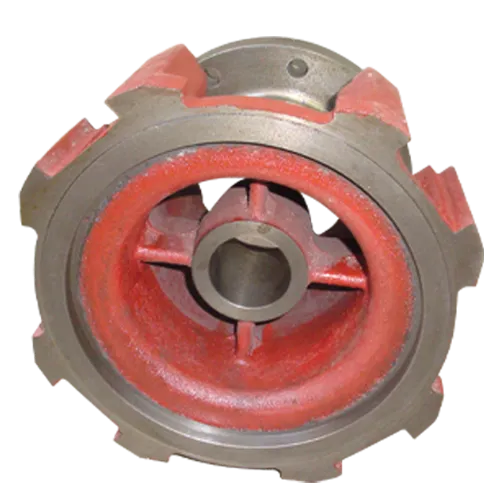

In pump manufacturing, the wetted components define performance, reliability, and lifecycle cost. Core elements include the impeller, pump casing, cap ends (end caps/cover plates), and the impeller for motor-driven assemblies. The impeller on pump controls hydraulic efficiency and head, while the pump casing sets the pressure boundary and influences NPSH and vibration. Cap ends secure alignment, sealing, and serviceability. Together, these precision-cast and CNC-finished components form the backbone of robust pumping systems for water, chemicals, energy, and mining.

Welcome To Hebei Yuanda Trade Co., Ltd. supplies OEM/ODM components produced via investment casting and sand casting with close dimensional control and consistent metallurgy. Options include stainless steels, duplex grades, high-chrome wear alloys, and bronzes to address corrosion and erosion in diverse media. Impellers are available in open, semi-open, and closed geometries, dynamically balanced for stable operation. Pump casings are engineered for wall-thickness uniformity and smooth passageways to reduce losses. As a reliable manufacturer, Yuanda supports drawing-based builds, reverse engineering from samples, and application-driven material selection to help B2B buyers standardize quality across global fleets.

Benefits & Use Cases of [impeller,impeller on pump,cap ends,pump casing,impeller for motor] in Pump manufacturing

Across water and wastewater, chemical processing, HVAC, power, and slurry handling, selecting the right impeller and pump casing determines throughput and uptime. An optimized impeller on pump reduces recirculation and cavitation risk, while precisely machined cap ends enable secure sealing and bearing alignment. For motor-driven units, an impeller for motor assemblies must balance efficiency, rigidity, and vibration control to protect seals and bearings.

Welcome To Hebei Yuanda Trade Co., Ltd. delivers competitive advantages: refined casting processes for smooth hydraulic surfaces, robust alloy choices for abrasive or corrosive media, and tight tolerances for drop-in interchangeability. Clients benefit from consistent vane profiles, accurate keyways and hub fits, and stable pressure containment in the pump casing. Typical use cases include retrofits to extend pump life, standardizing components across multi-site operations, and developing application-specific variants—such as thicker leading edges for slurry or duplex material upgrades for chlorides. Yuanda’s engineering support helps teams match geometry and material to duty points, enhancing efficiency and reducing total lifecycle costs.

Cost, Maintenance & User Experience

Total cost of ownership in pumping hinges on energy efficiency, wear rate, and maintenance intervals. A well-designed impeller and pump casing combination can yield measurable energy savings by minimizing hydraulic losses. Material upgrades—like duplex stainless or high-chrome iron—can extend wear life, delaying rebuilds and reducing downtime. Precision-machined cap ends further cut maintenance by maintaining concentricity and sealing integrity, while a balanced impeller for motor-driven sets limits vibration, prolonging mechanical seal and bearing life.

Customers in the manufacturing of pumps, valves, compressors, and similar machinery report smoother commissioning due to consistent fit and finish, along with fewer reworks. Field feedback highlights stable head-capacity curves after rebuilds and improved seal life when vane-to-shroud clearance is tightly controlled. From a budgeting perspective, marginal price differences in premium alloys are frequently offset by longer mean time between maintenance and reduced energy spend. Welcome To Hebei Yuanda Trade Co., Ltd. supports predictable procurement with drawing control, inspection records, and sampling to validate form, fit, and function before scaling.

Sustainability & Market Trends in General equipment manufacturing industry

Energy efficiency and longer component life are central to decarbonization in pumping systems. Efficient hydraulics and durable materials reduce energy intensity and waste from frequent rebuilds. As markets adopt tougher standards for pump efficiency and reliability, the role of a precisely engineered impeller on pump and robust pump casing grows. Manufacturers are also moving toward cleaner melting, higher recycled metal content, and process monitoring to reduce scrap and emissions.

Welcome To Hebei Yuanda Trade Co., Ltd. aligns with these trends by emphasizing quality consistency, streamlined casting yields, and application-specific designs that extend service life. B2B decision makers increasingly pair component upgrades with condition monitoring to support predictive maintenance and lower lifecycle carbon. In parallel, infrastructure investments in water, chemicals, and energy continue to expand pump demand, while buyers prioritize suppliers who can customize materials, geometries, and finishes to balance sustainability with performance. Yuanda’s flexible manufacturing approach positions clients to meet evolving regulations and ESG goals without compromising throughput or reliability.

Conclusion on [impeller,impeller on pump,cap ends,pump casing,impeller for motor] from Welcome To Hebei Yuanda Trade Co., Ltd.

For pump OEMs and asset owners, the right impeller, pump casing, cap ends, and impeller for motor directly influence efficiency, uptime, and lifecycle cost. Welcome To Hebei Yuanda Trade Co., Ltd. provides dependable, application-driven manufacturing that helps standardize quality and performance across fleets. From corrosion resistance to hydraulic optimization, our solutions are engineered to deliver measurable value in demanding environments.

Contact us: email: info@ydcastings.com

Visit our website: https://www.ydcastings.com

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025