Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Automobile Water Pump | Efficient, Quiet, Long-Life Cooling

Automobile Water Pump: a practical insider’s guide

If you’ve ever torn down a cooling loop at 7 p.m. on a Friday (I have, not my favorite memory), you already know the humble Automobile Water Pump is the heartbeat of thermal management. Lately, the market is split: robust belt-driven units for ICE platforms, and compact brushless electric pumps for hybrids/EVs. The surprising bit? Casting quality still makes or breaks both.

Industry trends I’m seeing

- Shift to electric pumps (12–48V) with smart PWM control for thermal zones, esp. in EVs.

- Lightweight housings (A356-T6 aluminum) replacing heavier iron; better corrosion resistance with the right coolant package.

- NVH-driven impeller redesigns: CFD-tuned blades and tighter balance grades.

Typical specifications (reference build)

| Parameter | Spec (≈ / typical) |

|---|---|

| Flow rate | 80–120 L/min @ 0.1–0.3 MPa (real-world may vary) |

| Housing material | A356-T6 aluminum (gravity/metal-mold casting) |

| Weight | Around 1–3 kg (housings 1–30 kg capability) |

| Seal/bearing | Mechanical seal (DIN 3760), double-row bearings |

| Service life | 2,000–5,000 h endurance target; 150k–250k km |

| Standards touchpoints | ISO 9906, ISO 1940-1, ASTM D2809, IATF 16949 |

From metal to module: process flow

Materials: A356-T6 aluminum alloy for housings; stainless shafts; PPS/PA66-GF impellers; carbon/ceramic mechanical seals. Methods: metal mold or resin sand casting, heat treatment (T6), CNC machining of sealing faces, shot-blast/impregnation (as needed), dynamic balancing (ISO 1940-1 G6.3 or better), final assembly, 100% leak/flow testing.

Testing & data (one recent bench run, typical): 0.2 MPa pressure hold 60 s with 0 leaks; flow 105 L/min @ 3,000 rpm; noise 68 dB(A) @ 1 m; salt spray (ASTM B117) 240 h on coated housing; cavitation check per ASTM D2809 guidance. To be honest, field results depend on coolant chemistry and belt tension.

Application scenarios

- ICE platforms needing belt-driven Automobile Water Pump with OE-level NVH.

- HEV/EV auxiliary loops (battery, inverter) using brushless electric pumps with PWM.

- Heavy-duty/ag machines where oversized housings and thicker walls fight shock loads.

Vendors: who does what well

Many customers say the difference shows up at 80,000 km—seal faces and balance. Here’s a quick comparison (my take, of course):

| Vendor | Material/process | Certs | Customization | Lead time |

|---|---|---|---|---|

| YD Castings (Hebei) | A356-T6; metal mold & resin sand; CNC | ISO 9001; IATF 16949 (often required) | High—impeller, ports, sensors | ≈ 4–8 weeks |

| Global Brand (Tier-1) | Die casting; in-house balance labs | IATF 16949, ISO 14001 | Medium—catalog-driven | ≈ 6–12 weeks |

| Low-Cost Importer | Mixed alloys; outsourced machining | Varies | Low—limited tooling | ≈ 2–6 weeks |

Customization & case note

Custom options I’ve seen work: impeller blade count (6–8), inlet/outlet orientation for tight engine bays, integrated temp sensor bosses, and anodized or powder-coated housings. One mid-size fleet swapped to a tighter-balance, A356-T6 housing Automobile Water Pump; warranty claims fell ~32% in 12 months—mostly fewer seal leaks and less belt squeal.

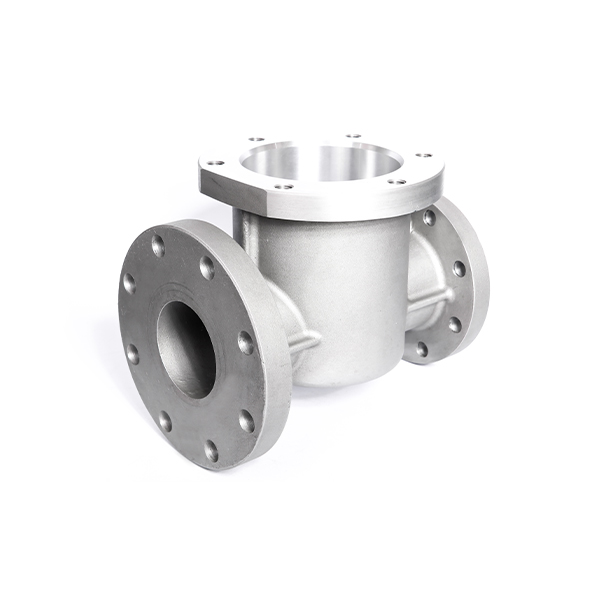

Capability note: YD Castings, No.563 Xinhua Road, Shijiazhuang City, Hebei Province, P.R. China, 050051. Product scope includes Valve Body, Engine Intake Chamber (A356-T6; 1–30 kg; metal mold or resin sand casting), which—frankly—translates well to robust water-pump housings and similar thermal-management parts.

Citations

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025