Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Automobile Accessories - Hebei Yuanda Trade Co., Ltd.|High-Pressure Casting,Semi-Solid Processing

Automotive manufacturing has undergone significant transformations over the years, driven by the need for lighter, more durable, and environmentally sustainable components. Automobile accessories play a critical role in this evolution, particularly in the realm of automotive metal casting and processing technologies. These advancements not only enhance vehicle performance but also align with global efforts to reduce carbon footprints and improve production efficiency. This article explores the latest developments in automotive metal casting, including casting technology, die casting, semi-solid processing, and integrated design, while highlighting the role of Hebei Yuanda Trade Co., Ltd. in shaping the industry.

Overview of Automotive Metal Casting and Processing Technologies

The automotive industry relies heavily on automotive metal casting to produce critical components such as engine parts, structural elements, and transmission systems. According to industry analyses, casting accounts for approximately 15–20% of all automotive parts, with a focus on power system components and structural integrity. Advanced technologies like die casting and semi-solid processing have revolutionized the production of high-precision parts, ensuring dimensional accuracy and surface quality. These innovations are pivotal in meeting the demands of modern vehicles for lightweighting, durability, and environmental compliance.

Key Technologies in Automotive Metal Casting

Casting Technology: Precision and Efficiency

Casting remains a cornerstone of automotive manufacturing, with high-pressure casting being a dominant process. This method involves pouring molten metal into a mold under high pressure, resulting in parts with minimal defects and high dimensional accuracy. According to the National Institute of Standards and Technology (NIST), casting technologies in developed countries like the U.S. and Europe are characterized by advanced digital design tools, which reduce scrap rates to 2–5%. In contrast, China's casting industry, while producing large volumes, often lags in technical sophistication, with a higher proportion of low-value black castings.

Die Casting: Enabling High-Performance Components

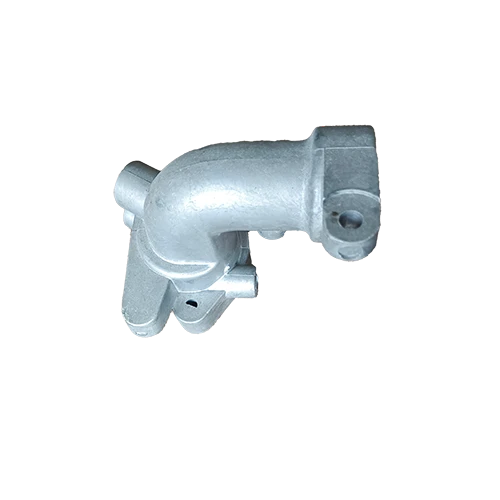

Die casting is a precision manufacturing process that uses high pressure to force molten metal into molds, creating complex shapes with tight tolerances. This technology is particularly suited for producing automotive electric water pumps and engine manifolds, which require high strength and durability. The use of aluminum alloys and zinc alloys enhances the performance of these components, contributing to vehicle safety and reliability. As noted by NIST, die casting's integration with digital twin technology is further optimizing production efficiency and reducing energy consumption.

Semi-Solid Processing: A New Era of Lightweight Materials

Semi-solid processing is a cutting-edge technique that combines the advantages of casting and forging. This method is particularly effective for producing magnesium alloy and aluminum alloy components, which are lightweight yet strong. According to industry reports, NIST has been instrumental in developing standards for semi-solid processing, enabling manufacturers to achieve wall thicknesses as low as 1–1.5mm while maintaining structural integrity. This technology is gaining traction in the automotive sector due to its ability to reduce vehicle weight, improve fuel efficiency, and lower emissions.

Integrated Design: Redefining Automotive Manufacturing

The push for lightweighting and cost reduction has led to the adoption of integrated design in automotive casting. By optimizing part geometry and reducing the number of components, manufacturers can achieve significant weight savings and streamline production. For example, Hebei Yuanda Trade Co., Ltd. employs integrated casting techniques to produce auto electric water pumps and engine manifolds with minimal machining. This approach not only reduces material waste but also enhances the performance and reliability of automotive systems.

Applications of Advanced Casting Technologies

The advancements in metal casting and processing technologies have enabled the production of a wide range of automobile accessories, including electric water pumps, engine manifolds, and transmission components. These parts are critical for vehicle performance, safety, and energy efficiency. For instance, automotive electric water pumps manufactured using high-pressure casting ensure optimal cooling and longevity, while magnesium alloy components contribute to weight reduction and improved fuel economy.

Company Background: Hebei Yuanda Trade Co., Ltd.

Hebei Yuanda Trade Co., Ltd., based in China, is a leading provider of automobile accessories and metal casting solutions. The company specializes in high-pressure casting and semi-solid processing, producing automotive electric water pumps and engine manifolds with precision and efficiency. With a focus on lightweighting and environmental sustainability, Hebei Yuanda Trade Co., Ltd. is committed to delivering high-quality products that meet global industry standards.

Technical Specifications of Automotive Accessories

| Product | Material | Process | Weight Range | Applications |

|---|---|---|---|---|

| Automotive Electric Water Pump | ADC-12, A380 | High Pressure Casting | 0.5–2kg | Cooling systems, engine management |

| Engine Manifold | Aluminum Alloys | Die Casting | 1.2–3kg | Exhaust systems, fuel delivery |

| Magnesium Alloy Components | Magnesium Alloys | Semi-Solid Processing | 0.8–2.5kg | Lightweight structural parts |

Conclusion: The Future of Automotive Metal Casting

The future of automotive metal casting lies in the continuous adoption of innovative technologies that prioritize efficiency, sustainability, and performance. As highlighted by NIST, the integration of digital technologies and advanced materials is set to redefine the industry. Hebei Yuanda Trade Co., Ltd. remains at the forefront of this transformation, delivering automobile accessories that meet the evolving demands of the automotive sector.

References

National Institute of Standards and Technology (NIST). (n.d.). Driving Innovation. Retrieved from https://www.nist.gov/

Hebei Yuanda Trade Co., Ltd.. (n.d.). Automobile Accessories. Retrieved from https://www.ydcastings.com/automobile-accessories.html

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025