Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Aluminum Sand Casting Production Solutions for Your Manufacturing Needs

Aluminum Sand Casting Manufacturer An Innovative Approach to Metal Fabrication

Aluminum sand casting is a widely utilized manufacturing process that plays a critical role in producing complex aluminum components for various industries. In recent years, the demand for aluminum sand castings has surged, given the lightweight, strength, and corrosion resistance of aluminum. This article explores the significance of aluminum sand casting manufacturers, their methods, advantages, and the future of this innovative manufacturing process.

The Process of Aluminum Sand Casting

The aluminum sand casting process involves creating a mold from a sand mixture, into which molten aluminum is poured to form the desired shape. This age-old technique begins with designing the component, followed by creating a pattern made from wood, metal, or plastic. The pattern is placed in a mold box, and a mixture of sand and a bonding agent is packed around the pattern to create a mold. After removing the pattern, the mold is ready to receive molten aluminum.

Once the aluminum is melted, it is poured into the mold cavity. After sufficient cooling, the sand mold is broken away, and the aluminum casting is cleaned and finished. This process allows for the production of intricate designs, varying thicknesses, and a high degree of dimensional accuracy, making it suitable for a myriad of applications.

Advantages of Aluminum Sand Casting

1. Versatility One of the primary advantages of aluminum sand casting is its versatility. Manufacturers can create intricate shapes and sizes that would be impossible with other machining methods. This makes it ideal for producing components for automotive, aerospace, marine, and many other industries.

2. Cost-Effectiveness Sand casting is often more economical for low to medium production runs compared to other casting methods. The use of inexpensive raw materials, coupled with the ability to reconfigure molds, allows manufacturers to minimize costs while maintaining high-quality production.

4. Excellent Strength-to-Weight Ratio Aluminum offers a high strength-to-weight ratio, meaning it can withstand significant stress without adding excessive weight. This property makes it an ideal choice for load-bearing applications.

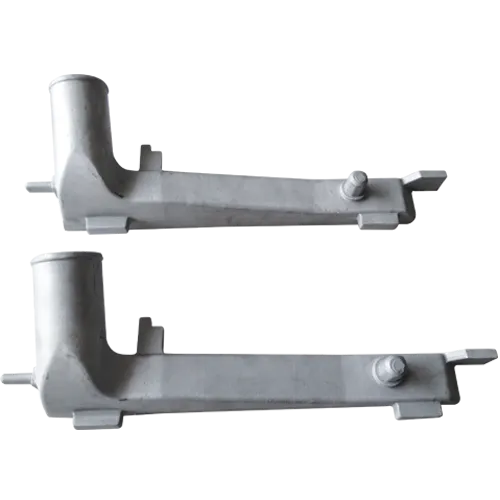

aluminum sand casting manufacturer

5. Enhanced Corrosion Resistance Aluminum is naturally resistant to corrosion, which is a substantial advantage for components exposed to harsh environmental conditions.

The Role of Manufacturers in the Industry

The role of aluminum sand casting manufacturers extends beyond mere production; they are pivotal in the entire supply chain. From design consulting and prototyping to full-scale production and post-casting finishing, these companies provide invaluable support to their clients. Effective communication and collaboration with customers ensure that the final product meets the required specifications and quality standards.

Advanced technology has transformed the aluminum sand casting industry. Many manufacturers now utilize computer-aided design (CAD) and computer-aided manufacturing (CAM) software to optimize the design and production processes, resulting in improved efficiency and reduced lead times. Additionally, the integration of 3D printing techniques for creating molds has allowed for more complex geometries and quicker turnaround times.

Sustainability in Aluminum Sand Casting

As industries worldwide increasingly focus on sustainability, aluminum sand casting manufacturers are adopting eco-friendly practices. Recycling aluminum is a significant aspect of the industry, as it allows the reuse of materials and reduces waste. Furthermore, manufacturers are exploring energy-efficient melting processes and sustainable sand options to minimize their environmental footprint.

Future Trends in Aluminum Sand Casting

Looking ahead, the future of aluminum sand casting appears promising. Innovations in materials, processes, and technologies are paving the way for advancements that will enhance efficiency and sustainability. The rise of Industry 4.0, with its emphasis on automation and data exchange, will further drive improvements in quality control and production processes.

In conclusion, aluminum sand casting manufacturers play a vital role in shaping the manufacturing landscape. By harnessing the advantages of aluminum casting and embracing technological advancements, these manufacturers are well-positioned to meet the evolving demands of industries worldwide. As we move towards a more sustainable and efficient future, the aluminum sand casting process will undoubtedly continue to play an essential role in the production of high-quality components across various sectors.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025