Mobile:+86-311-808-126-83

Email:info@ydcastings.com

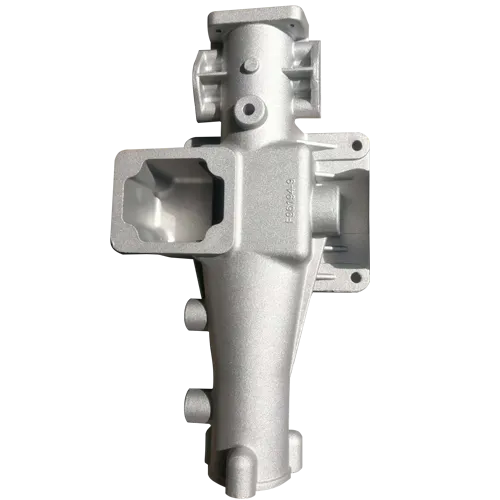

aluminum investment casting

Aluminum Investment Casting A Comprehensive Overview

Aluminum investment casting is a highly effective manufacturing process that combines the flexibility of design with the precision of production. This method is particularly favored in various industries, including aerospace, automotive, and consumer products, owing to its ability to create intricate shapes and components from aluminum, a lightweight and corrosion-resistant metal.

What is Investment Casting?

Investment casting, also known as lost-wax casting, is a manufacturing technique that dates back thousands of years. The process involves creating a wax model of the desired component, which is then encased in a ceramic shell. Once the shell hardens, the wax is melted away, leaving a hollow cavity in the shape of the part. Molten aluminum is then poured into this cavity, solidifying to form the final product. This method enables the production of complex geometries and fine details that would be difficult or impossible to achieve with traditional casting techniques.

Advantages of Aluminum Investment Casting

1. Precision and Detail One of the most significant advantages of investment casting is its ability to produce parts with outstanding dimensional accuracy and surface finish. Features such as intricate patterns, smooth surfaces, and thin walls can be achieved, often requiring little or no machining after casting.

2. Material Efficiency Investment casting is known for its minimal waste production. The process can use up to 98% of the material, making it a cost-effective and resource-efficient option. This is crucial in today’s economy where sustainability and cost savings are paramount.

3. Versatility Aluminum investment casting is highly versatile, allowing for the production of a wide variety of shapes and sizes. This flexibility enables manufacturers to meet the specific needs of different industries, accommodating unique design requirements.

4. Strength and Durability Aluminum castings exhibit excellent mechanical properties, including high strength-to-weight ratios and good fatigue resistance. This makes them ideal for applications in demanding environments, such as in the aerospace sector where weight and strength are critical considerations.

aluminum investment casting

Applications of Aluminum Investment Casting

The applications of aluminum investment casting are vast

. In the aerospace industry, manufacturers utilize this process to create lightweight components like brackets, housings, and other structural parts that contribute to reducing overall aircraft weight, enhancing fuel efficiency.In the automotive sector, aluminum investment casting is employed to produce various engine components, transmission housings, and suspension parts. The lightweight nature of aluminum contributes to improved vehicle performance and fuel economy, making it a popular choice among car manufacturers.

Furthermore, industries such as electronics, medical devices, and consumer products leverage aluminum investment casting for producing intricate parts that require exact specifications and high-quality finishes.

Challenges and Considerations

Despite its many advantages, aluminum investment casting is not without challenges. The initial setup costs can be higher compared to other casting methods, mainly due to the complex tooling required to create the wax models and ceramic shells. Additionally, the process can be sensitive to temperature fluctuations, which may affect the final quality of the casting.

Moreover, achieving consistent results requires a skilled workforce and stringent quality control measures. Investment casting also has limitations regarding the size of parts that can be produced, as very large components may be impractical to cast due to the constraints of equipment.

Conclusion

Aluminum investment casting is a sophisticated manufacturing process that blends precision, efficiency, and versatility. Its ability to produce complex shapes with excellent material properties makes it a preferred choice in various high-performance applications. As industries continue to innovate and pursue advancements in manufacturing technologies, aluminum investment casting will undoubtedly remain a vital component in the landscape of modern production methods. With ongoing improvements and adaptations, the potential for this casting technique is vast, making it an exciting area for future development.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025