Mobile:+86-311-808-126-83

Email:info@ydcastings.com

aluminum die casting supplier

The Importance of Choosing the Right Aluminum Die Casting Supplier

Aluminum die casting is a manufacturing process that allows for the production of complex parts with high precision and smooth surfaces. This method has gained immense popularity in various industries, including automotive, aerospace, electronics, and consumer goods. When considering aluminum die casting for your projects, choosing the right supplier is crucial. It can significantly impact the quality, cost-efficiency, and overall success of your production. Here, we will discuss the essential factors you should consider while selecting an aluminum die casting supplier.

Expertise and Experience

One of the first factors to consider is the expertise and experience of the supplier. An experienced aluminum die casting supplier will have a deep understanding of the manufacturing process, including design, tooling, and finishing. They should have a proven track record of delivering high-quality parts on time. Ask potential suppliers about their experience in your specific industry and request references or case studies that demonstrate their capabilities.

Technical Capabilities

The technical capabilities of a supplier are vital to the success of your aluminum die casting project. Ensure that the supplier possesses advanced machinery and technology that can meet your specifications. They should also have skilled technicians who can handle complex designs and maintain high precision throughout the production process. Additionally, inquire about their capacity for prototyping, as this can be crucial for testing and refining your designs before mass production.

Material Quality

The quality of aluminum used in the die casting process is paramount. A reliable supplier should source high-quality aluminum alloys that meet industry standards. Discuss the types of aluminum alloys they offer and their chemical compositions. This is especially important if your parts will be subjected to extreme conditions or require specific mechanical properties. The right supplier will also be able to provide certifications for the materials used.

Customization and Design Support

aluminum die casting supplier

Every project is unique, and sometimes off-the-shelf solutions do not meet all requirements. Look for a supplier that offers customization options and can provide design support. They should help you refine your design for manufacturability, taking into account aspects like wall thickness, draft angles, and overall geometry. A collaborative approach in the design phase can lead to better part performance and reduced production costs.

Quality Assurance Processes

Quality assurance is a critical aspect of the die casting process. Make sure that the supplier has rigorous quality control measures in place. This includes regular inspections, testing during various production stages, and adhering to industry standards such as ISO certifications. A commitment to quality ensures that the final products meet your specifications and are reliable in their intended applications.

Lead Times and Flexibility

In today’s fast-paced market, shorter lead times can provide a competitive edge. Discuss the supplier’s production capacity and lead times for delivering parts. It’s important to find a balance between quality and speed. Additionally, assess their flexibility in handling changes in order volumes or last-minute design modifications. A supplier that can adapt to your needs will streamline your overall production process.

Pricing and Terms

Finally, consider the pricing structure and terms of the supplier. While cost is an important factor, it should not be the sole criterion for selecting a supplier. Analyze the overall value they provide, considering factors like material quality, customer service, and technical support. Request detailed quotes and clarify any hidden costs to ensure that you make an informed decision.

Conclusion

Selecting the right aluminum die casting supplier is vital for the success of your manufacturing project. By considering factors such as expertise, technical capabilities, material quality, and flexibility, you can find a partner that meets your needs and drives your business forward. A strong relationship with a reliable supplier can lead to improved production efficiency and product quality, ultimately benefiting your bottom line in a competitive marketplace.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

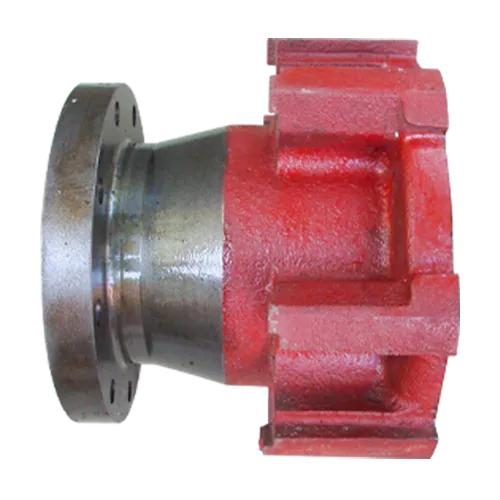

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025