Mobile:+86-311-808-126-83

Email:info@ydcastings.com

aluminum die casting supplier

The Role of Aluminum Die Casting Suppliers in Modern Manufacturing

In today's competitive manufacturing landscape, aluminum die casting suppliers play a crucial role in providing high-quality, cost-effective components for a myriad of industries. The versatility and desirable properties of aluminum make it an ideal material for die casting, as it offers excellent strength-to-weight ratios, corrosion resistance, and thermal conductivity. This article explores the significance of aluminum die casting suppliers, the advantages of aluminum die casting, and the factors to consider when selecting a supplier.

Understanding Aluminum Die Casting

Aluminum die casting is a manufacturing process that involves forcing molten aluminum alloy into a mold under high pressure. This method is renowned for producing intricate shapes with tight tolerances, making it a popular choice for automotive, aerospace, electronics, and consumer goods manufacturing. The process can be automated, which increases efficiency and reduces labor costs, thereby making it an attractive solution for large production runs.

Advantages of Aluminum Die Casting

1. Lightweight and Durable Aluminum die casting components are significantly lighter than those made from other metals, such as steel, which can enhance the overall performance of the final product. The lightweight nature of aluminum not only reduces transportation costs but also improves fuel efficiency in vehicles.

2. Corrosion Resistance Aluminum naturally forms a protective oxide layer, making it highly resistant to corrosion. This property extends the lifecycle of products, especially in harsh environments, thereby reducing replacement expenses.

3. Design Flexibility The ability to produce complex shapes and designs with high precision is one of the standout features of aluminum die casting. This flexibility allows manufacturers to innovate without the constraints often associated with traditional machining methods.

4. Cost-Effectiveness While the initial tooling cost for die casting may be higher compared to other methods, the long-term savings associated with reduced machining and labor costs make it an economically viable option for mass production.

5. Recyclability Aluminum is one of the most recycled materials globally. The ability to recycle aluminum helps manufacturers reduce their overall environmental footprint, making aluminum die casting an eco-friendly choice.

aluminum die casting supplier

Choosing the Right Aluminum Die Casting Supplier

When selecting an aluminum die casting supplier, several factors should be taken into consideration to ensure quality, reliability, and a partnership that aligns with your business goals.

1. Experience and Reputation Look for suppliers with a proven track record in the industry. Their experience not only influences the quality of the products but also ensures they understand the challenges and requirements specific to your sector.

2. Quality Assurance Quality control is paramount in manufacturing. A reputable supplier will have robust quality assurance processes, including certifications such as ISO 9001, to ensure that they meet industry standards.

3. Technical Capabilities Consider the supplier's technological advancements and capabilities. Suppliers that utilize state-of-the-art machinery and software for designing and testing can provide superior results.

4. Customization Options Every project is unique; hence, it’s important to partner with a supplier that can offer customization options to meet specific design requirements.

5. Customer Support An effective communication and support structure is vital. A good supplier should have an accessible team that can address inquiries, provide updates, and assist with any potential issues throughout the manufacturing process.

6. Sustainability Practices The growing importance of sustainable manufacturing practices is changing how businesses operate. Suppliers who emphasize green manufacturing processes and materials can align with your company's environmental goals.

Conclusion

Aluminum die casting suppliers are integral to modern manufacturing, enabling industries to produce strong, lightweight, and durable components efficiently. By understanding the advantages of aluminum die casting and carefully selecting a reliable supplier, manufacturers can enhance product quality, reduce costs, and respond to market demands swiftly. As the industry continues to evolve, the relationship between manufacturers and aluminum die casting suppliers will be key to driving innovation and success.

-

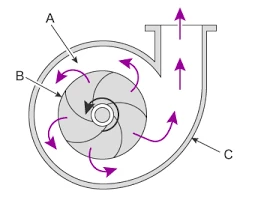

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025