Mobile:+86-311-808-126-83

Email:info@ydcastings.com

aluminum die casting manufacturer

The Importance of Aluminum Die Casting Manufacturers in Modern Industry

Aluminum die casting has become a fundamental process in modern manufacturing, thanks to its ability to produce complex shapes with high precision and excellent surface finishes. The demand for lightweight, durable, and cost-effective materials has led industries to increasingly rely on aluminum die casting. In this article, we will explore the critical role of aluminum die casting manufacturers, the process itself, its advantages, and the various industries that utilize this remarkable technique.

Understanding Aluminum Die Casting

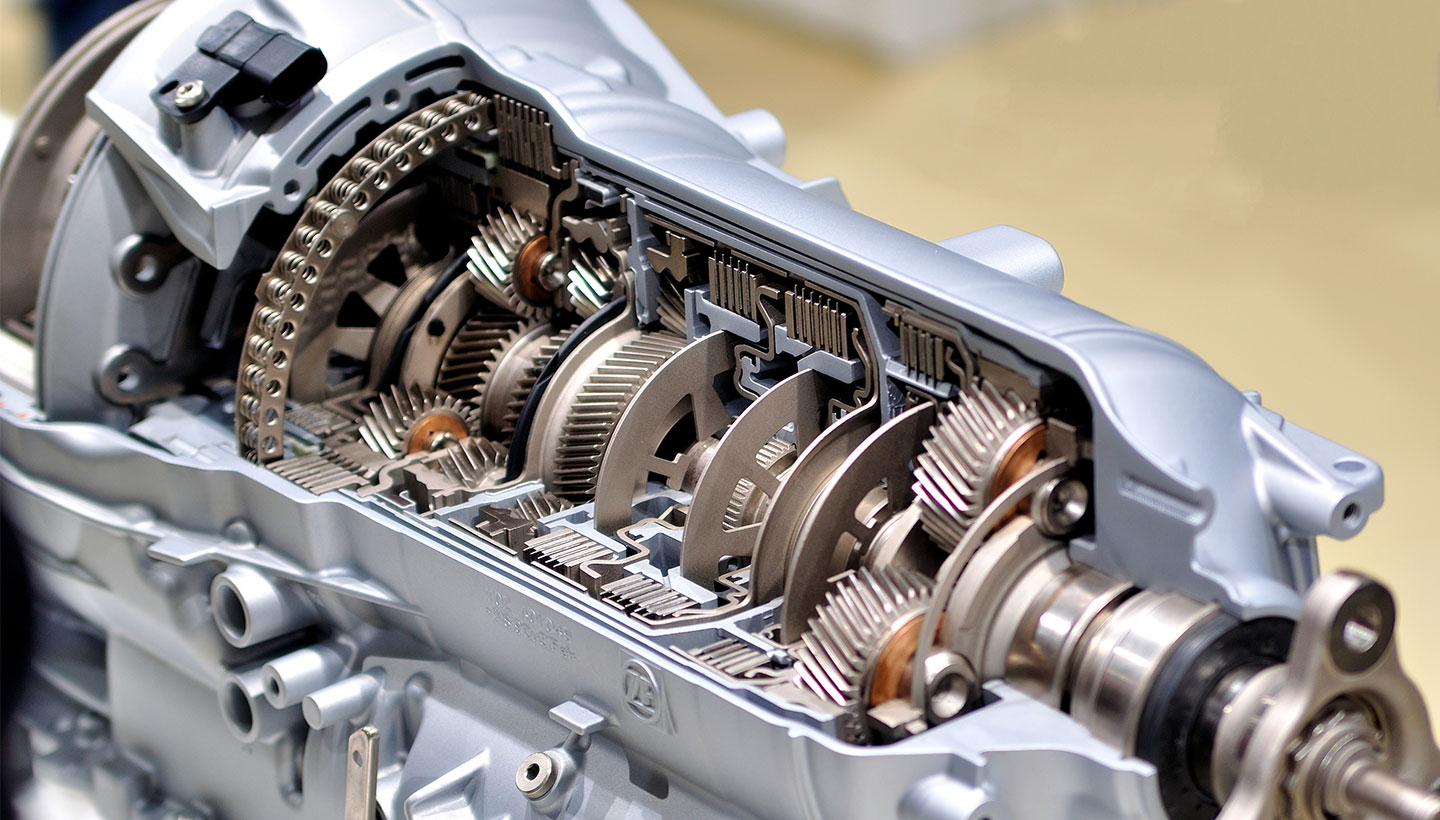

Aluminum die casting is a manufacturing process that involves injecting molten aluminum into pre-prepared molds, known as dies. These dies are usually made from steel and are designed to withstand the high pressure and temperature of molten metal. The process can be conducted in two primary methods high-pressure die casting and low-pressure die casting. High-pressure die casting is more common and is primarily used for mass production, while low-pressure die casting is used for larger components where a more gradual filling method is necessary.

The process is characterized by its speed, precision, and the ability to create intricate designs. Complex designs can be produced in a single operation, reducing the need for secondary machining processes. This manufacturing method is especially useful in producing parts with thin walls and large surface areas, which are usually challenging to achieve through other techniques.

Advantages of Aluminum Die Casting

1. High Precision Aluminum die casting allows for tight tolerances and high dimensional accuracy. This makes it an ideal choice for industries where precision is paramount, such as automotive and aerospace manufacturing.

2. Cost-Effectiveness Although the initial investment in creating a die can be high, the long-term cost savings are significant. High-volume production reduces per-unit costs, making aluminum die casting an economical choice for large production runs.

3. Lightweight and Strong Aluminum is inherently lightweight and its durability makes it an excellent choice for many applications. The lightweight nature of aluminum parts helps manufacturers to meet stringent weight requirements in sectors like automotive and aerospace.

4. Excellent Surface Finish Parts produced through aluminum die casting feature superior surface finishes. The process can produce surfaces that require minimal or no secondary finishing operations, thus saving time and reducing costs.

Role of Aluminum Die Casting Manufacturers

aluminum die casting manufacturer

Aluminum die casting manufacturers play a crucial role in the supply chain of many industries. They not only produce the components but also often provide design assistance, prototype development, and secondary operations such as machining, plating, and assembly. This comprehensive service offering allows manufacturers to streamline their production processes and enhance efficiency.

Furthermore, these manufacturers invest in advanced technologies and techniques to improve production capabilities. Automation and robotics are increasingly being integrated into die casting facilities, enhancing precision and speed while reducing labor costs. Manufacturers are also adopting environmentally friendly practices and materials, including the recycling of aluminum scraps, which aligns with the global trend towards sustainability.

Industries That Benefit from Aluminum Die Casting

Aluminum die casting is utilized in a wide array of industries, including

- Automotive Components such as engine blocks, transmission cases, and various brackets and housings benefit from the lightweight and durable nature of aluminum.

- Aerospace The aerospace industry relies on aluminum die casting for lightweight parts that meet stringent safety and performance standards.

- Electronics Housing for electronic devices, heat sinks, and chassis can all be produced through aluminum die casting, ensuring protection and performance for high-tech applications.

- Consumer Products Many household items and appliances utilize aluminum die cast parts due to their light weight and durability.

- Industrial Equipment Machinery and tools often require custom die cast components to ensure optimal performance.

Conclusion

In conclusion, aluminum die casting manufacturers are instrumental in meeting the growing demands of various industries. Their ability to produce high-quality, lightweight, and precise components makes aluminum die casting a preferred choice in modern manufacturing. As technology continues to evolve, these manufacturers will likely adopt more innovative manufacturing processes, further solidifying the role of aluminum die casting in the future of industrial production. The combination of quality, efficiency, and versatility ensures that aluminum die casting will remain a cornerstone in manufacturing for years to come.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025