Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Aluminum Gravity Die Casting | High Precision Castings Manufacturer

Introduction to Aluminum Gravity Die Casting

Aluminum gravity die casting is a highly efficient and versatile manufacturing process used to create intricate metal components with superior surface finishes and dimensional accuracy. This method employs gravity to fill the mold, allowing liquid aluminum to flow into a pre-defined cavity. It is particularly suitable for producing medium to high-volume components, making it a popular choice in various industries, including automotive, aerospace, and electronics.

Process Overview

The aluminum gravity die casting process begins with the creation of a mold, typically made from high-quality steel. These molds are designed to withstand the high temperatures and pressures associated with the casting process. Once the mold is ready, it is heated to ensure optimal flow of the molten aluminum and to prevent premature solidification.

Molten aluminum is then poured into the mold, using gravity to assist the filling process. This method allows for better control over the metal flow, reducing entrapment of air and minimizing the occurrence of defects. The casting is allowed to cool and solidify within the mold, after which it is removed and subjected to secondary processes like machining or surface treatment to achieve the final specifications.

Advantages of Aluminum Gravity Die Casting

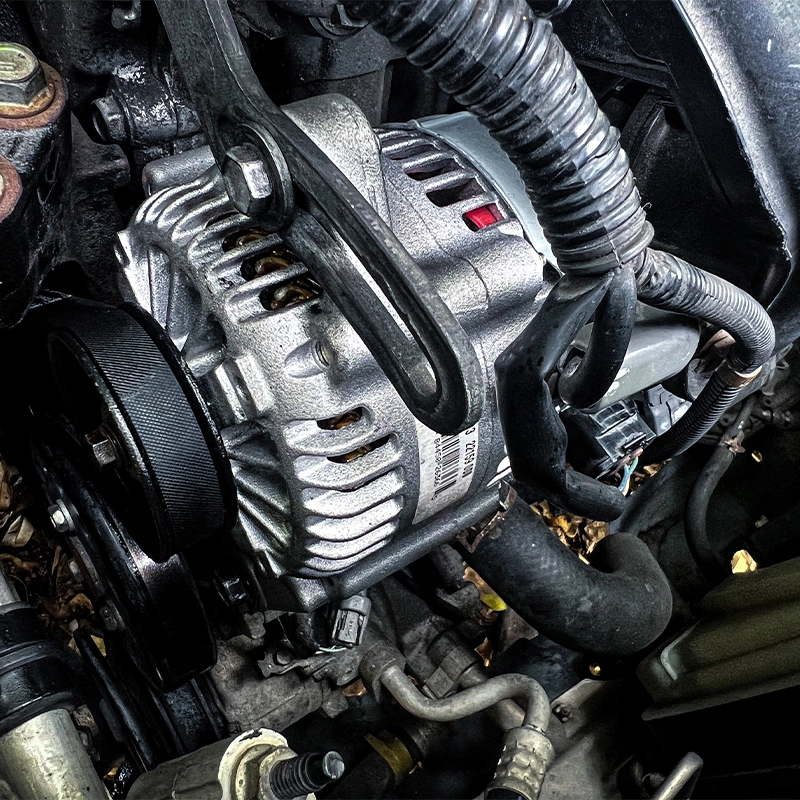

aluminum gravity die casting

One of the primary advantages of aluminum gravity die casting is its ability to produce complex geometries with excellent surface finishes. The precision of the process reduces the need for extensive machining, thus saving time and costs. Furthermore, aluminum is a lightweight yet strong material, which makes it ideal for applications where weight savings are crucial, such as in the automotive and aerospace sectors.

Another significant benefit is the reduction of material waste. The process is capable of producing near-net-shape components, meaning that less excess material is generated compared to other casting methods. This not only lowers production costs but also supports eco-friendly manufacturing practices.

Applications

Aluminum gravity die casting is used to manufacture a wide range of products, including engine components, transmission housings, and intricate decorative parts. Its application is particularly noted in the automotive industry, where lightweight and high-strength parts are essential for enhancing fuel efficiency and overall vehicle performance. Additionally, it finds uses in the production of consumer electronics, industrial equipment, and various mechanical components.

Conclusion

In summary, aluminum gravity die casting is a robust manufacturing process that leverages the advantages of aluminum's properties and the precision of gravity-fed techniques. With its ability to create high-quality, complex parts efficiently, it plays a crucial role in driving innovation across numerous industries. As technology advances, the demand for aluminum gravity die casting is expected to grow, paving the way for further developments in casting techniques and applications.