Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Jul . 10, 2024 20:45

Back to list

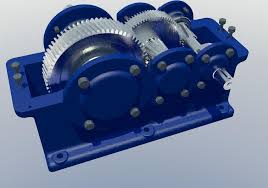

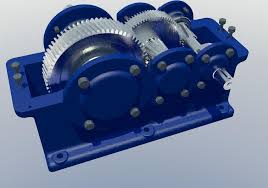

Aluminum die casting mold for precision manufacturing of metal components.

Aluminium die casting is a popular process used in the manufacturing industry to create complex and high-quality parts with excellent dimensional accuracy. The process involves injecting molten aluminium into a steel mould at high pressure to produce a specific shape. The mould used in this process, known as an aluminium die casting mould, plays a crucial role in ensuring the final product meets the desired specifications.

Aluminium die casting moulds are typically made from high-grade steel materials, such as tool steel or H13 steel, to withstand the high temperatures and pressures involved in the die casting process. These moulds are designed with intricate cavity and core shapes that define the final shape and features of the casted part. The construction of the moulds also includes cooling channels to regulate the temperature of the molten metal during the casting process, ensuring consistent quality and reducing cycle times.

The design of an aluminium die casting mould is critical to achieving the desired part geometry, surface finish, and mechanical properties. Mould designers must consider factors such as draft angles, wall thickness, and fillet radii to facilitate the flow of molten aluminium and prevent defects like shrinkage or porosity

aluminium die casting mould. Advanced computer-aided design (CAD) software is often used to simulate and optimize the mould design before production to ensure accuracy and efficiency. The maintenance of aluminium die casting moulds is essential to prolong their lifespan and ensure consistent part quality. Regular cleaning, lubrication, and inspection of the moulds are necessary to prevent wear and damage caused by the high-temperature molten metal and the high-pressure injection process. Proper maintenance practices can help extend the life of the moulds and reduce the risk of production downtime due to mould failures. In conclusion, aluminium die casting moulds are critical components in the die casting process, influencing the quality, efficiency, and cost-effectiveness of producing aluminium parts. Proper design, construction, and maintenance of these moulds are essential to achieving high-quality casted parts with precise dimensions and surface finishes. By investing in high-quality mould materials, advanced design technologies, and proactive maintenance practices, manufacturers can optimize their die casting operations and deliver superior products to their customers.

aluminium die casting mould. Advanced computer-aided design (CAD) software is often used to simulate and optimize the mould design before production to ensure accuracy and efficiency. The maintenance of aluminium die casting moulds is essential to prolong their lifespan and ensure consistent part quality. Regular cleaning, lubrication, and inspection of the moulds are necessary to prevent wear and damage caused by the high-temperature molten metal and the high-pressure injection process. Proper maintenance practices can help extend the life of the moulds and reduce the risk of production downtime due to mould failures. In conclusion, aluminium die casting moulds are critical components in the die casting process, influencing the quality, efficiency, and cost-effectiveness of producing aluminium parts. Proper design, construction, and maintenance of these moulds are essential to achieving high-quality casted parts with precise dimensions and surface finishes. By investing in high-quality mould materials, advanced design technologies, and proactive maintenance practices, manufacturers can optimize their die casting operations and deliver superior products to their customers.

Latest news

-

Why Is Choosing the Right Motor Housing Critical for Engine Performance?NewsJul.18,2025

-

Which Impeller Types Best Optimize Your Pump’s Efficiency?NewsJul.18,2025

-

Optimize Maintenance Efficiency with Durable Oil Catch SolutionsNewsJul.18,2025

-

Maximize Pump Performance with Precision-Engineered ComponentsNewsJul.18,2025

-

Elevate Industrial Flow Systems with Precision-Engineered ComponentsNewsJul.18,2025

-

Boost Durability and Functionality with Precision Power CastingsNewsJul.18,2025

Related PRODUCTS