Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Leading Manufacturers of Aluminum Casting Solutions for Diverse Applications Worldwide

The Role of Aluminum Casting Manufacturers in Modern Industry

Aluminum casting has become an essential process in various industries due to its lightweight, high strength, and corrosion-resistant properties. As technologies evolve and the demand for efficient, high-quality components grows, the role of aluminum casting manufacturers has become increasingly critical. This article delves into the significance of these manufacturers, exploring their methods, benefits, and contributions to the economy and sustainability.

Understanding Aluminum Casting

Aluminum casting involves pouring molten aluminum into a mold to create intricate shapes and parts. This process can be carried out using different techniques, such as sand casting, permanent mold casting, and die casting, each with its own set of advantages and applications. Manufacturers typically choose a method based on factors such as the required precision, surface finish, and production volume.

Key Techniques Employed by Manufacturers

1. Sand Casting This is one of the oldest and most versatile casting methods. It involves creating a mold from sand, which is then filled with molten aluminum. Sand casting is ideal for producing large, complex parts and is widely used in industries ranging from automotive to aerospace.

2. Permanent Mold Casting In this method, molds are made from metal, allowing for better dimensional accuracy and surface finish than sand casting. This method is often used for smaller production runs and parts that require high precision, such as engine blocks and transmission cases.

3. Die Casting Die casting is a high-speed production process where molten aluminum is forced into reusable steel molds under high pressure. This technique is well-suited for producing a large number of small to medium-sized parts with excellent dimensional integrity, making it popular in the automotive industry for components like valves and housings.

aluminium casting manufacturers

Benefits of Aluminum Casting

The advantages of aluminum casting are numerous. Firstly, aluminum is lightweight, which translates to fuel savings and reduced emissions in the transportation sector. Secondly, its excellent corrosion resistance increases the lifespan of components, leading to lower maintenance costs. Moreover, aluminum casting allows for complex shapes that may be challenging to achieve with other manufacturing methods.

Additionally, aluminum is infinitely recyclable without losing its properties, making it an environmentally friendly option. The recycling process consumes only about 5% of the energy required to produce primary aluminum, highlighting its sustainability credentials. Manufacturers are increasingly focusing on practices that promote recycling, ensuring that aluminum waste is minimized and repurposed.

Economic Contributions

Aluminum casting manufacturers play a vital role in the economy. They not only provide jobs but also contribute to local and national economic growth through their operations. The demand for lightweight, durable parts has skyrocketed in industries such as automotive, aerospace, and consumer electronics, fueling the growth of casting manufacturers.

Furthermore, as the world moves towards greener technologies, these manufacturers are innovating to meet the evolving needs of their customers. This includes investing in research and development to improve casting techniques, enhance material quality, and reduce energy consumption during production.

Conclusion

In conclusion, aluminum casting manufacturers are at the forefront of modern manufacturing, providing essential components for a wide range of industries. Their expertise in various casting techniques, coupled with the inherent benefits of aluminum, positions them uniquely in a competitive market. As industries push for more sustainable practices, the role of these manufacturers will continue to expand, ensuring they remain integral to future innovations and economic stability. Their commitment to quality, efficiency, and sustainability makes them a cornerstone of the manufacturing landscape, poised to meet the challenges of tomorrow.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

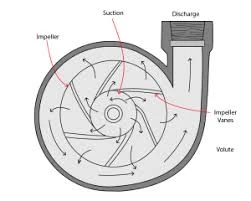

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025