Mobile:+86-311-808-126-83

Email:info@ydcastings.com

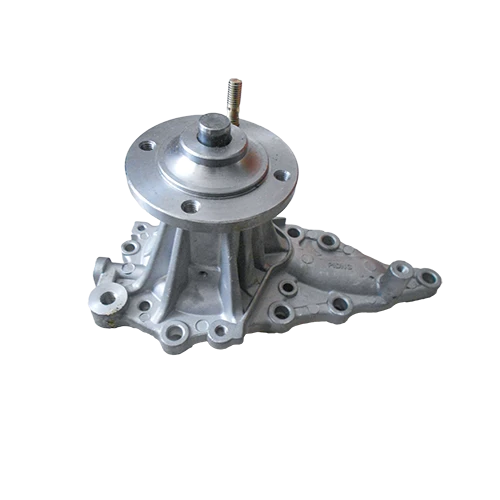

aluminium alloy die casting

Understanding Aluminum Alloy Die Casting

Aluminum alloy die casting is a highly efficient manufacturing process that involves the creation of precise aluminum parts through the melting and injection of aluminum alloys into specifically designed molds. This method is favored for its ability to produce complex shapes with excellent surface finishes and tight tolerances, making it ideal for a range of industries including automotive, aerospace, electronics, and consumer goods.

Understanding Aluminum Alloy Die Casting

The die casting process begins with the preparation of aluminum alloy, which is melted in a furnace at temperatures around 660 degrees Celsius (about 1220 degrees Fahrenheit). Once molten, the aluminum is injected into a steel mold under high pressure. This pressure ensures that the molten aluminum fills every crevice of the mold, resulting in parts that are both detailed and robust. After the aluminum cools and solidifies, the mold is opened, and the finished part is ejected, ready for any post-processing treatments such as machining or surface finishing.

aluminium alloy die casting

Another key benefit of aluminum alloy die casting is its production efficiency. The process allows for high-volume manufacturing, significantly reducing production lead times compared to other metalworking methods. Additionally, the durability of the molds used in die casting can lead to lower costs per unit as production scales up. With advancements in technology, such as the implementation of computer-aided design (CAD) and simulation tools, manufacturers can optimize mold designs and casting parameters, further enhancing efficiency and reducing waste.

Sustainability is also an important consideration in modern manufacturing. Aluminum is highly recyclable, and the die casting process can utilize recycled aluminum scrap, minimizing waste and lowering energy consumption. This focus on sustainability aligns with global efforts to reduce environmental impact and promote responsible manufacturing practices.

In conclusion, aluminum alloy die casting stands out as a versatile and efficient method for producing high-quality metal components. Its combination of lightweight strength, production efficiency, and environmental advantages make it a preferred choice in various industries. As technology continues to evolve, the potential for aluminum die casting will expand, opening new avenues for innovation and development in manufacturing processes. The future of aluminum alloy die casting is certainly bright, promising to deliver even more benefits to manufacturers and consumers alike.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025