Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Affordable Aluminium Die Casting Prices | Quality Services

Understanding Aluminium Die Casting Prices

Aluminium die casting is a widely used manufacturing process that enables the production of complex shapes and components with high precision. This method is favored in various industries, including automotive, aerospace, and consumer electronics, due to its ability to produce lightweight yet strong parts. However, one critical aspect that manufacturers and businesses must consider is the pricing associated with aluminium die casting.

The pricing of aluminium die casting is influenced by several factors, which can be broadly categorized into material costs, tooling expenses, production volume, and additional finishing processes.

Material Costs

The first and foremost consideration is the cost of raw materials, namely aluminium alloy. Aluminium prices can fluctuate based on market demand, availability, and global economic conditions. As such, manufacturers must stay informed about prevailing market rates for aluminium to accurately estimate costs. Additionally, the choice of alloy can impact the price, as different aluminium alloys have varying compositions and characteristics, affecting both performance and cost.

Tooling Expenses

Another significant component of die casting pricing is the tooling cost. The process requires specially designed molds, which can be expensive to create. The initial investment in dies can range from a few thousand to tens of thousands of dollars, depending on the complexity of the design and the size of the parts being produced. It's worth noting that while the upfront costs may seem high, the longevity and efficiency of these tools can lead to cost savings over large production runs.

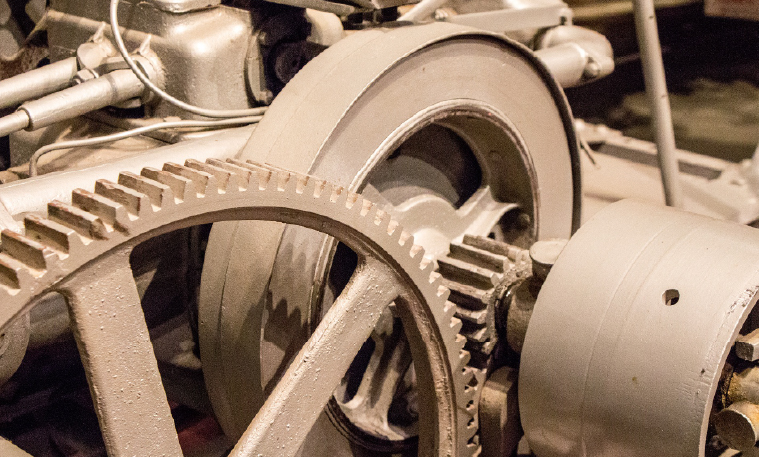

aluminium die casting price

Production Volume

The volume of production also dramatically affects the pricing structure. In die casting, the more parts you produce, the lower the cost per unit becomes. This is due to the fixed costs associated with tooling and setup being spread over a larger quantity of products. For businesses that can commit to high-volume orders, they can negotiate better pricing due to economies of scale. Conversely, low-volume orders may incur higher per-unit costs, making it essential for companies to evaluate their production needs carefully.

Finishing Processes

After the die casting process itself, many products require additional finishing treatments such as machining, surface coating, or anodizing. These processes can add to the overall cost of the final product but may be necessary to achieve the desired quality and appearance. Businesses must consider these potential secondary costs when budgeting for aluminium die casting projects.

Conclusion

In summary, the price of aluminium die casting encompasses a variety of factors, each of which plays a crucial role in determining the final cost of the components. By evaluating material costs, tooling expenses, production volumes, and finishing processes, manufacturers and buyers can make informed decisions that balance quality and budget. As the demand for aluminium die-cast products continues to grow across industries, understanding these nuances will be key for businesses looking to leverage the benefits of this efficient manufacturing process. Ensuring communication with suppliers and evaluating market trends will also be essential in obtaining the best possible pricing while meeting production needs.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025