Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Alternative Solutions for Tubular End Caps in Various Applications

Understanding Tubular End Caps Importance and Applications

Tubular end caps are essential components utilized across various industries, offering crucial finishing touches to tubular structures. These caps serve to enclose the ends of tubes and pipes, providing protection against environmental factors, preventing the ingress of contaminants, and ensuring the structural integrity of the system. This article delves into the characteristics, types, and applications of tubular end caps, highlighting their significance in modern manufacturing and industrial practices.

What Are Tubular End Caps?

Tubular end caps are fittings that cover the ends of cylindrical objects, such as pipes and tubes. They are typically made from materials like plastics, metals, or rubber, depending on the specifications of their intended application. These caps are designed to fit snugly over the ends of tubes, creating a seal that keeps out dirt, moisture, and other harmful elements. They come in various sizes and shapes to accommodate a range of tubular dimensions and designs.

Types of Tubular End Caps

There are several types of tubular end caps, each suited for specific uses. Common types include

1. Plastic End Caps These are lightweight and resistant to corrosion, making them suitable for wet or humid environments. They are commonly used in plumbing, furniture, and automotive applications.

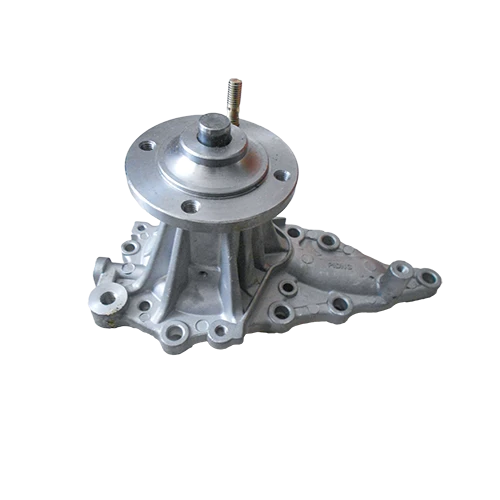

2. Metal End Caps Metal caps, often made from stainless steel or aluminum, provide high durability and resistance to heat and pressure. They are widely used in industrial applications where strength and reliability are critical.

3. Rubber End Caps These caps offer flexibility and a tight seal, making them ideal for applications that require vibration resistance or where the fit must accommodate slight variations in tube size.

4. Threaded End Caps Featuring internal threads, these caps can be easily screwed onto a pipe or tube, providing a secure connection. They are particularly useful in plumbing and hydraulic systems.

tubular end cap

5. Snap-On End Caps These caps snap in place, offering a quick and convenient sealing solution. They are often used in consumer products and lightweight applications.

Applications of Tubular End Caps

Tubular end caps find applications in numerous fields, including

- Construction In construction, end caps are used to seal steel or PVC pipes, preventing water infiltration and potential structural damage.

- Automotive In the automotive industry, these caps are employed to cover open ends of exhaust pipes and mufflers, protecting them from rust and debris.

- Furniture Many furniture items, such as chairs and tables, use tubular end caps to create a polished appearance while protecting the ends of metal or plastic legs from scratches and damage.

- Plumbing In plumbing systems, tubular end caps help to test pipe integrity and seal off unused sections, allowing for easier maintenance and repairs.

- Electronics In electronic devices, end caps are used to protect wiring and components, ensuring longevity and reliability.

Conclusion

In summary, tubular end caps play a fundamental role in various industries, providing protection, durability, and aesthetic appeal to tubular structures. Their availability in multiple materials and designs ensures that there is a suitable option for nearly any application, ranging from heavy industrial usage to everyday consumer products. As technology and materials continue to advance, tubular end caps will undoubtedly evolve, further enhancing their effectiveness and utility in an ever-changing marketplace. Understanding their importance and versatility can lead to better product design and maintenance strategies, ultimately contributing to efficiency and longevity in many applications.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025