Mobile:+86-311-808-126-83

Email:info@ydcastings.com

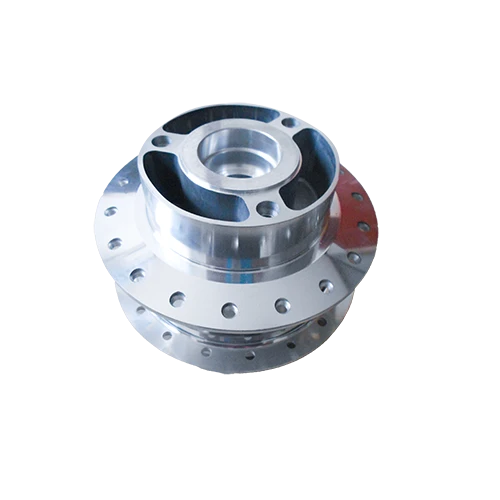

air pump manifold connector

Understanding Air Pump Manifold Connectors A Key Component in Pneumatic Systems

In the world of pneumatic systems, one component that plays a critical role is the air pump manifold connector. These connectors serve as the link between the air pump and the manifold, facilitating the efficient transfer of compressed air to various tools and machines. Understanding their design, function, and applications can greatly enhance the efficiency of pneumatic systems.

What is an Air Pump Manifold Connector?

An air pump manifold connector is a fitting that connects the output of an air pump to a manifold— a component that distributes air to multiple outlets. The manifold typically feeds air to different tools, cylinders, or actuators in a production line or workshop. This connector must ensure a secure, leak-free connection to maintain optimal performance and prevent loss of pressure.

Air pump manifold connectors are usually made from durable materials such as aluminum, brass, or reinforced plastics, as they must withstand high pressures and the corrosive effects of lubricants and coolants often found in pneumatic systems. Additionally, these connectors come in various sizes and designs to accommodate different types of manifolds and air pumps, which makes them highly versatile.

The Importance of Air Pump Manifold Connectors

1. Efficiency in Air Distribution One of the primary functions of the air pump manifold connector is to ensure that compressed air is evenly distributed to all connected tools and machines. A well-designed connector minimizes pressure drop, optimizing the performance of the pneumatic system.

2. Leak Prevention Air leaks can significantly reduce the efficiency of a pneumatic system, leading to increased energy costs and potential downtime in operations. High-quality manifold connectors are designed to provide a tight seal, reducing the risk of air leaks.

3. Ease of Maintenance Many air pump manifold connectors are designed for easy installation and maintenance. Quick-connect features allow operators to swiftly detach and reattach connections, facilitating quick repairs or changes in the setup.

4. Safety By securely connecting the air pump to the manifold, these connectors also play a safety role. A loose or faulty connection could lead to sudden releases of compressed air, posing risks to operators and nearby equipment.

Types of Air Pump Manifold Connectors

Air pump manifold connectors come in various types, each suited for specific applications

air pump manifold connector

- Quick Disconnect Connectors These are often used in applications where tools need to be frequently swapped out. They allow for rapid connection and disconnection without the need for additional tools.

- Barbed Connectors Typically used with flexible hoses, barbed connectors snap into place, providing a secure fit that is less likely to disconnect accidentally.

- Threaded Connectors For applications requiring a more permanent connection, threaded connectors can provide a leak-free seal. These may require tools for installation and removal but are highly reliable.

- Push-to-Connect fittings These connectors allow for easy, tool-free connections. Users can simply push the hose or tubing into the connector, which locks it in place.

Applications of Air Pump Manifold Connectors

Air pump manifold connectors find uses across various industries, including

- Manufacturing In factories, these connectors are essential for powering pneumatic tools, robotic arms, and assembly lines.

- Automotive Used in workshops, they connect air pumps to spray guns, tire inflators, and pneumatic wrenches, allowing for efficient vehicle maintenance.

- Construction Air tools like nail guns and concrete vibrators rely on manifold connectors for their operation.

- Medical In hospitals, they are used in various medical devices that require compressed air for operation.

Conclusion

Air pump manifold connectors are a vital component in pneumatic systems, ensuring efficient air distribution and reliable connections between air pumps and manifolds. By choosing the right type of connector for specific applications, users can enhance the performance, safety, and efficiency of their pneumatic operations. Understanding these connectors, their design, and their importance is essential for anyone working with compressed air systems, underscoring their pivotal role in modern industrial applications.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025